Midway through the analysis, the argon ran out, and error code 11011: Vacuum (IF/BK) time out, vacuum too high to start turbo pump, appeared. I've attempted a full system restart, but the same error persists

Midway through the analysis, the argon ran out, and error code 11011: Vacuum (IF/BK) time out, vacuum too high to start turbo pump, appeared. I've attempted a full system restart, but the same error persists

Hello! There is the Error 1101... It could be probably generated due to an incomplete closure of the gate-valve. The gate-valve separates (when closed) the vacuum chamber (where is vacuum) from the outside and is driven by Argon pressure, thus, when the Argon pressure sadly drops, the gate-valve can't close because there is not enough pressure to push it. To check that you have to remove the cones and the assembly of lenses behind the cones. Behind the lenses should be no hole further into the vacuum chamber but just a silvery black wall (circular shape). If the gate is not closed, it could be maneuvered (by a service engineer) into open and then closed state, from the Service interface of Mass Hunter (the Ar should be on and you need to have a proper pressure).

Is there any procedure to perform the closure by myself? I am in Colombia, and the technical service is terrible; I have been waiting for an engineer for over a week. Is it possible for me to do it myself?

You must first check if this is the issue. If it is the case, you can ask the engineer to log remotely to your PC, by TeamViewer or so, and set it on or off remotely from Mass Hunter. The main problem is that you need a Service password to access the Service interface, but since you are not trained by Agilent you can not have access to that interface.

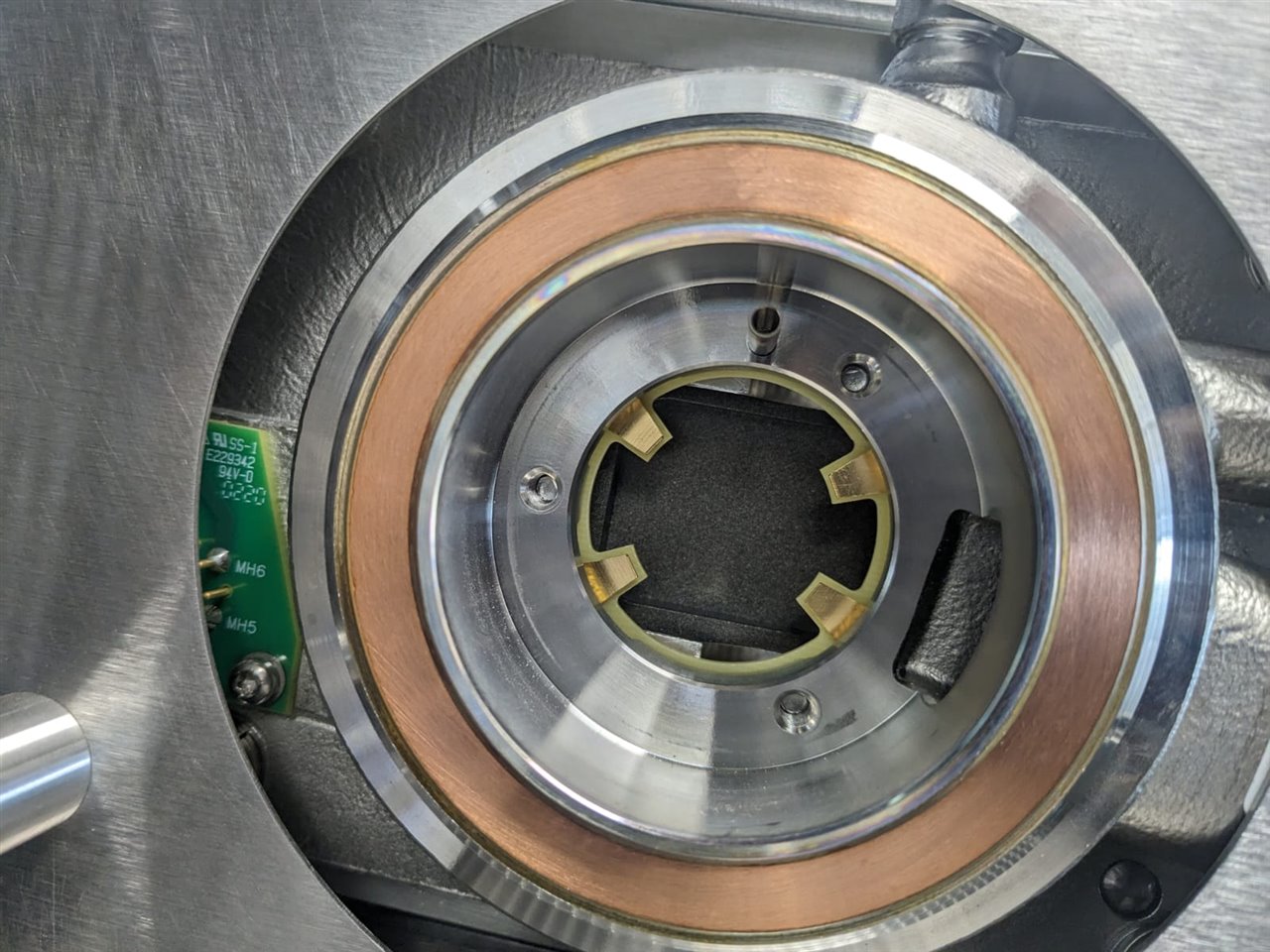

So, remove the lenses and send him, or here, a picture of what you see in that remaining space... we need to see if the valve is on or off...

You must first check if this is the issue. If it is the case, you can ask the engineer to log remotely to your PC, by TeamViewer or so, and set it on or off remotely from Mass Hunter. The main problem is that you need a Service password to access the Service interface, but since you are not trained by Agilent you can not have access to that interface.

So, remove the lenses and send him, or here, a picture of what you see in that remaining space... we need to see if the valve is on or off...

Amazing! I will do that. Thank you so much

I already removed the lenses and I think the gate valve is closed:

Maybe if I change the O-Ring, it will help? Thank you

The IF/Bk errors are also related with the graphite gasket or the cones, the dimensions of the orifices. But, in this case is strange, because the missing of argon does not influence that... check also with other cones.

Ok, I'm cleaning the cones, changing the graphite gasket and I will replace the oil on the pump as well to see if it works.

Larger are the orifices of the cones, particularly the sample cone, more chance you have to get the IF/Bk pressure errors. Usually when the sample cone is too used then is passing too much air or whatever trough it at the interface, and the ICP senses a pressure much higher than expected, and will not start the turbo. Better use a new Sample cone. Yes, the oil in the preliminary pump may help, but may not be the cause.

1101 Error: Vacuum (BK) time out, vacuum too high to start turbo pump.

The turbomolecular pump cannot work because the vacuum pressure (IF/BK) is not

below the limit within the prescribed time (When the instrument is changing from

Shutdown mode to Standby mode).

Check the vacuum pressure (IF/BK). The following causes are inferred.

• The vent valve is not closed or the seal is incomplete.

• The cover of the vacuum chamber is not closed or the seal is incomplete.

• The power of the foreline pump is not connected or the breaker is OFF.

• The foreline pump oil level is low or the oil is dirty.

• There is a leak in the gate valve.

• The vacuum tubing has failed (the tubing is off, or a leak is caused by an incomplete seal such

as a pin hole or a defective O-ring).

• There is a fault in the Pirani gauge (IF/BK) or the Connection PCA.

• There is a leak in the backing line, between turbo pump backing port to foreline pump inlet.