I am using the RapID RAMAN and to read KRAFT paper bag together with a transparent plastic bag the system indicates a low value of r, my question is, what should the parameters be to be able to read this type of container?

I am using the RapID RAMAN and to read KRAFT paper bag together with a transparent plastic bag the system indicates a low value of r, my question is, what should the parameters be to be able to read this type of container?

Hi, there is a actually a good guide to develop methods with RapID and it gives standard settings for common containers. please find it attached.

frederic

Hi

I already have this guide, what I do not see in this guide are the containers such as cardboard boxes and cardboard cans too, one of the materials comes in a blue bottle as well as a black plastic bag and a transparent bag too, then at at the time of reading, the spectrum of the sample does not show what we require

Hi,

Where are you located? I think it would be good for us to get on the phone with you to discuss your questions.

We are not mentioning the containers that you mentioned in your post because they will likely not work with SORS.

SORS spectroscopy cannot be used to analyze raw materials directly through fiber boards drums, carboard drums like the ones you are showing on the picture above. The laser light does not go through this type of containers and therefore why you are not seeing the desired spectra. I suspect that you are seeing a lot of noise plus a few cellulose peaks with some fluorescence as the spectra that you are collecting. For cardboard or fiberboard conainer, you will need to open them up and scan the material throught the primary packaging which is typically a plastic transparent liner.

For the blue bottle or blue drum that you are mentioning, SORS may or may not be usable. It depends on the raw material that you have inside. Can you be a bit more specific on this? If it is an API, there is a good likelyhood that SORS will be able to acquire the signal of your API inside that blue drum but if it is a weak scatterer, it probably will not work. When SORS does not work directly through the blue drum, you will need to open the container and scan the material through the primary transparent container.

For the black plastic, light is typically fully adsorbed by the back plastic bag, and, creates a hot point and you might see needle size hole on the bag you are trying to go through. This type of bag is typically used to actually protect the container or the material from any light source (be it ambient or artificial like the laser for SORS). For this bag, you will need to open the bag and sample through the transparent primary container inside (provided there is no additional container).

SORS will work with all transparent bags (to the exception of aluminum foil bag). In this case, you can use the clear bag example in the manual for the settings.

Please let me know if this makes sense.

My name is Frederic Prulliere. I work for Agilent Technologies as the product manager for the RapID and other SORS based products for raw material ID verification. I can be reached directly by email at frederic_prulliere@agilent.com or by phone at 00-1-864-320-8625.

Cordially,

Frederic

Hi Frederic good morning, , i´m México

Hi Frederic good morning, , i´m México

I have the following problem,

I have the following problem,

Generating my report of the first batch, in the last box comes the following legend Overal Batch Results FAIL, as you can see, our batch was 720 samples and there were 44 failed readings,

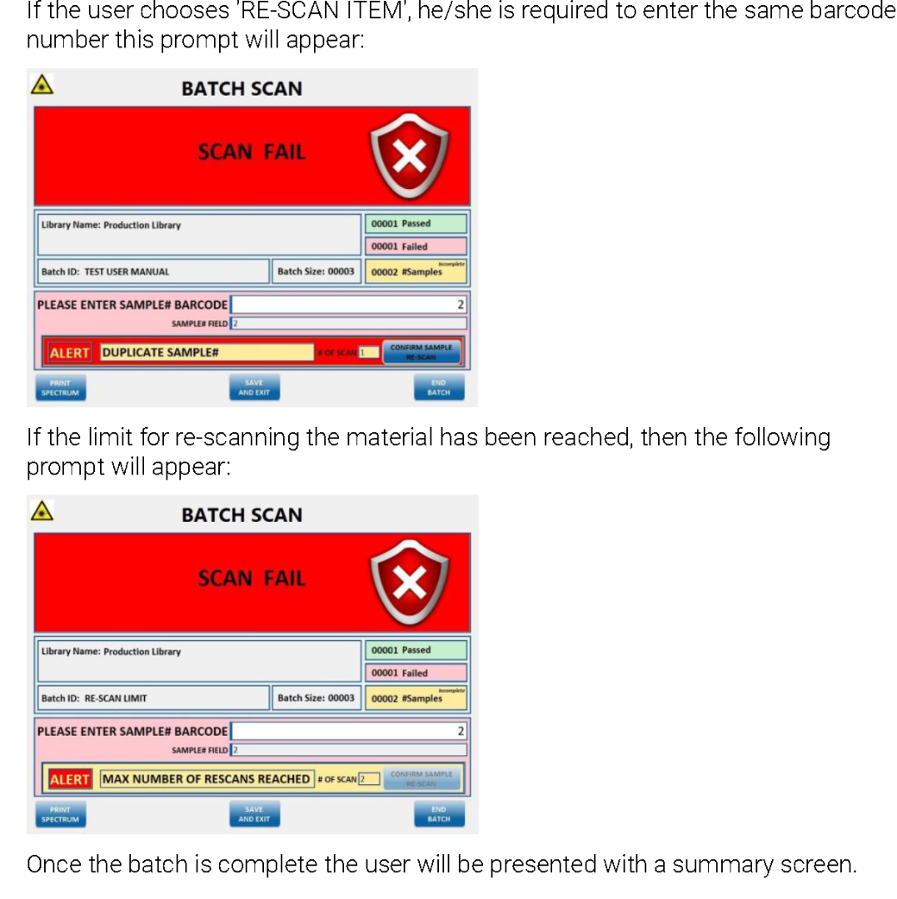

The question is the following, How do I modify the system so that in the result or summary of the scanned Lot it does not indicate that there was FAIL? All this was due to what I show the following

where I see or modify the configuration so that the failed reads can be re-scanned and thus not influence the final report, as it happened to me and I show it as follows

since the re-escan does not appear to me

I appreciate the attention and support for these questions

regards

Hello,

Your question brings some additional questions for me.

You mentioned that your rescans are failing eventhough the product is correct. Is your method robust enough. You should not see many fails in a batch if the instrument is properly operated (i.e. no user error) or if the raw material/container varies within the boundaries of the method.

If you are still looking to have a no fail batch after this if you have failed scans, this would require a new report.

We have asked through our local representative your database to check on your request.

Cordially,

Frederic