Hello,

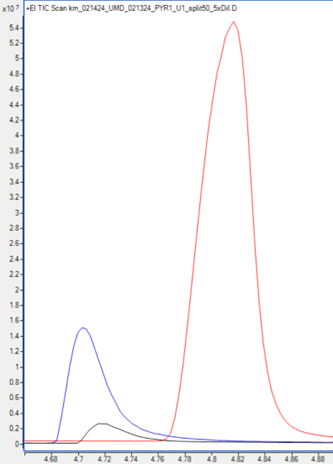

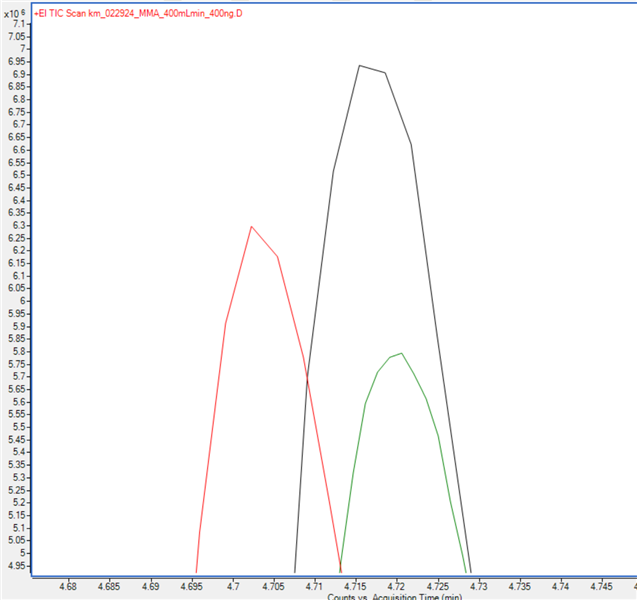

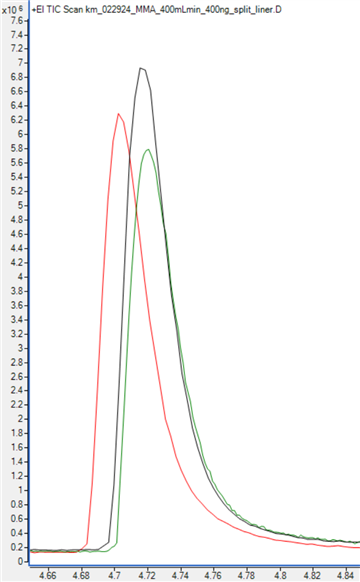

I am trying to increase the range of my calibration curve but I have problems with saturation. First, if the integration list says the peak is saturated, does that mean the peak area is unreliable to use in the calibration curve? In the attached image, the red peak is the standard extract with 10:1 split ratio, the blue peak is the same extract with 50:1 split ratio, and the black peak is 5x diluted extract with 50:1 split ratio. According to the integration list only the black peak is saturated even though we know less analyte has been injected. How does this saturation relate to concentration? I am also assuming the saturation has to do with the number of data points at the peak. Are there certain MS parameters I should adjust to eliminate the saturation? I am also interested in advice to reduce the tailing as concentration decreases.