Dear All,

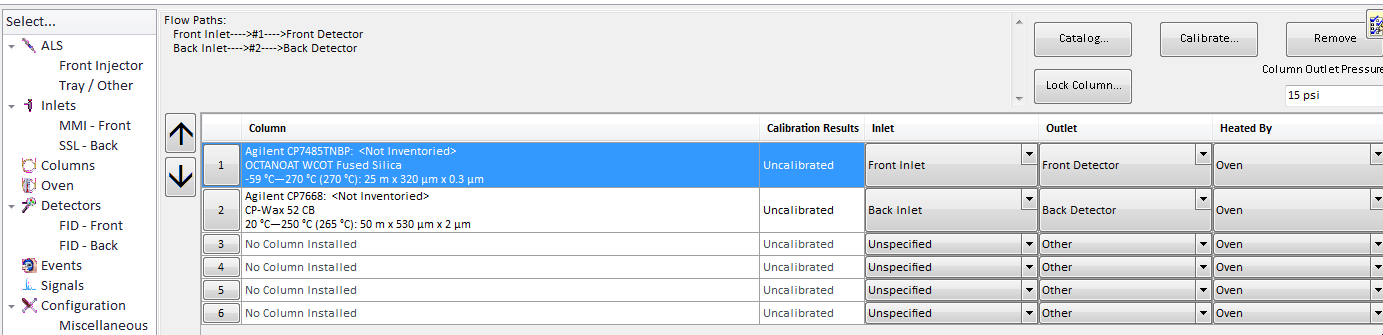

I analysed samples and standards with GC-7890b for CH4, N2O and CO2. I could see the peaks for each gas in each sample during running and everything was normal.

When the work of machine has been finished, I checked the result out, I can't see peaks and I saw this message for each sample: Warning: calibrated compound not found!

Could you please give me advice about this problem? Do you think I can fix it?

Thank you so much,

Milad