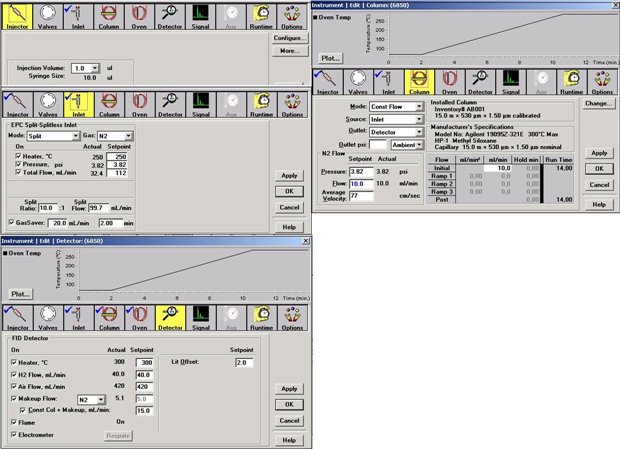

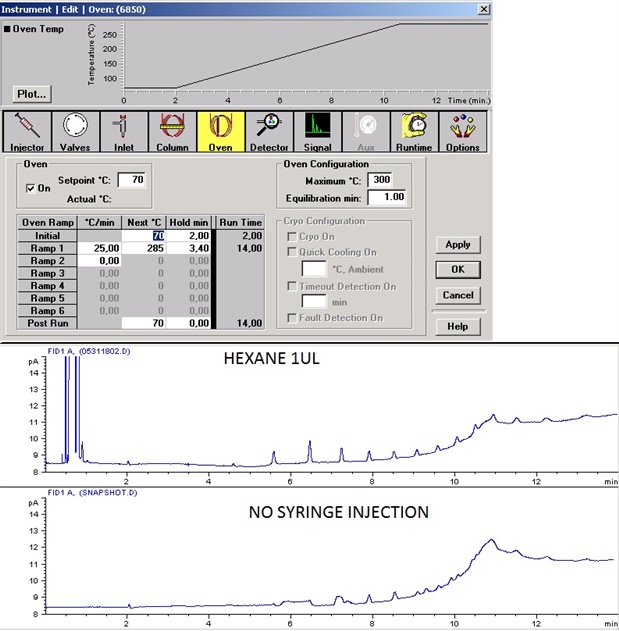

Hi guys, I'm experiencing regular times ghost peaks starting at 120°C to 295°C.....my setup is GC-FID 6890, Low pressure drop, Ultra Inert Liner with glass wool, column HP1 widebore.....

I have cutted the inj/det 5 inches of column, heated at 295°C with 1mL/min Nitrogen flow, changed the liner...but nothing has changed.

The column is new, I only injected few samples of "ketones" in acetone.

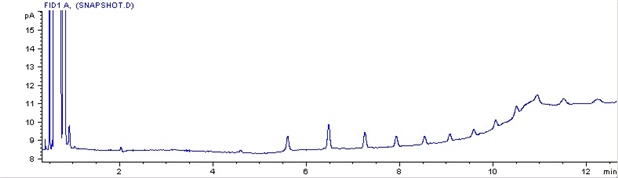

The analysis below is a vial of HEXANE; I have those regular ghost peaks injecting acetone or acetonitrile as well.

THANX