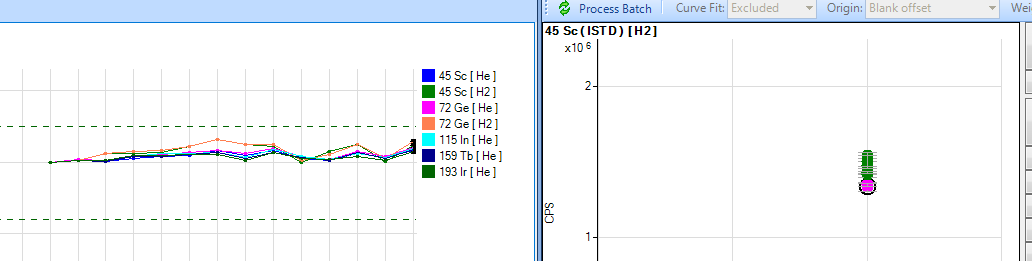

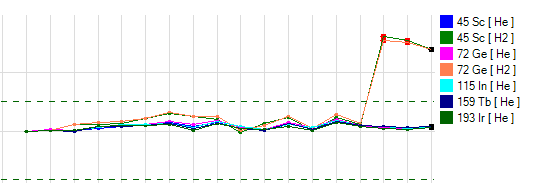

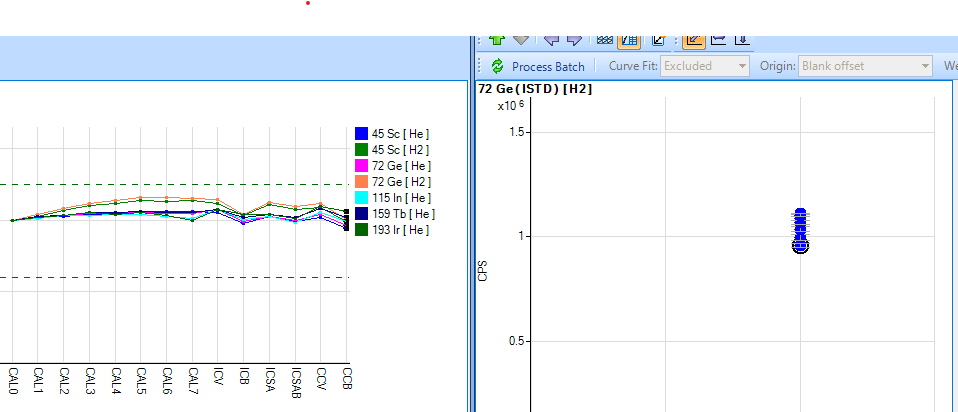

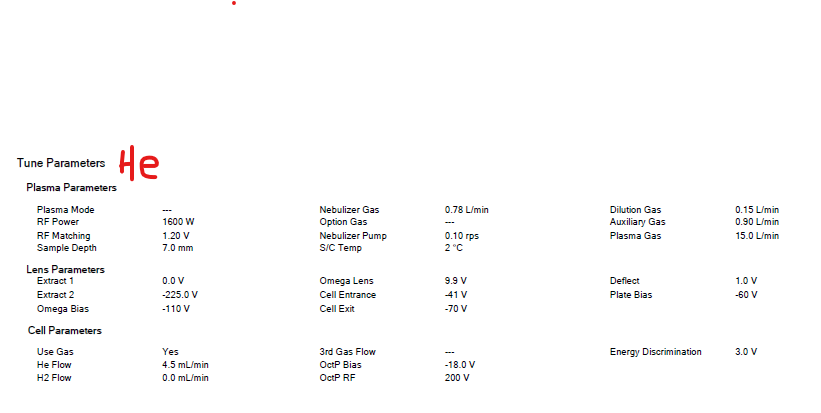

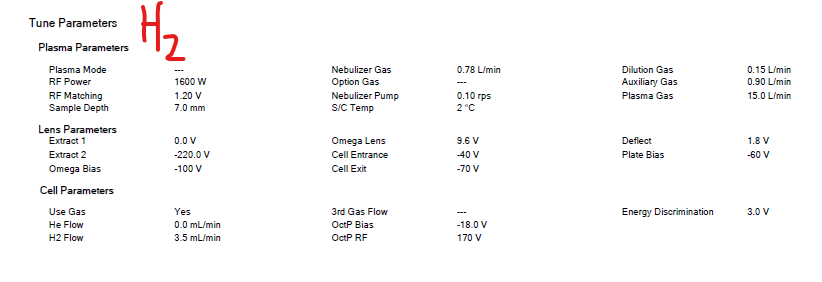

I've been having problems with my internal standards (running methods 200.8 and 6020B). The H2 standards tend to split off from the He standards. Every morning I just do an auto tune, do you think it has to do with the fact that the tune settings are different between gas modes?