Hello,

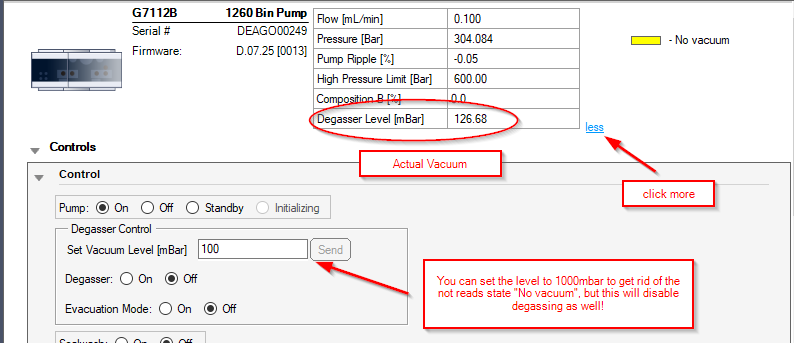

I've just yesterday encountered a problem with our HPLC (Agilent 1220 LC model). After a full day of sample prep I found I couldn't run my sequence as my gradient pump would never switch to ready in Chemstation. Scrolling over the pump status gives the error "no vacuum" insinuating that the degasser is faulty. I called support and was told we likely have to replace the degasser.

My question is is there anything that could cause this other than the degasser before we go ahead and replace that part? Could any tubing or frits be causing a leak that would be a much easier fix, etc? This is my first encounter having to go through repairs like this on this type of instrumentation so any help, suggestions to try, or troubleshooting tips are appreciated.