Does 502 split running Autotune? What are your tune targets for this tune -- tune ion relative abundances and peak widths? What is the carrier gas and column flow?

What is the DC Polarity listed on the sticker on the analyzer - is it Pos or Neg? See: (+) Quadrupole DC Polarity - what it means and how to check it - Files - GC/MS - Agilent Community

Hi Paul,

To answer your questions:

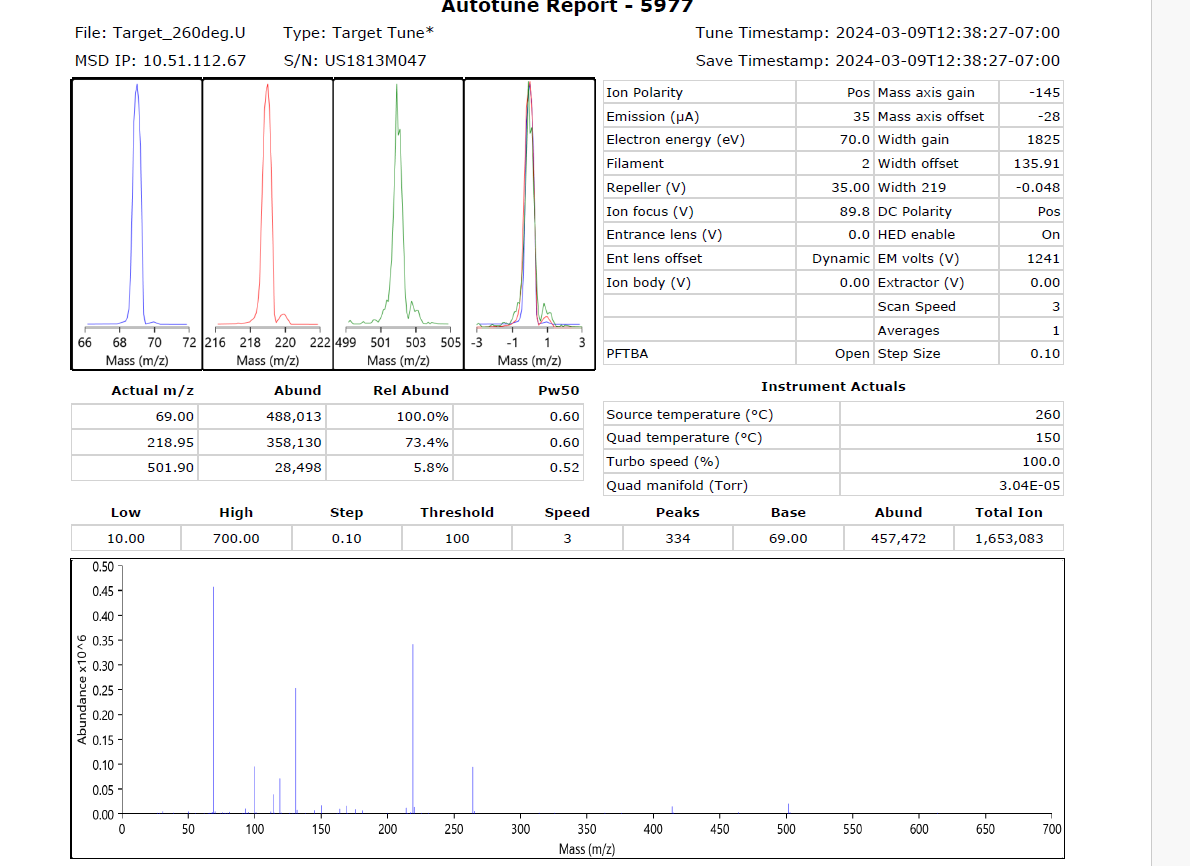

Does 502 split running Autotune? I have not ran an autotune, just our target tune

What are your tune targets for this tune -- tune ion relative abundances and peak widths? See below

What is the carrier gas and column flow? Carrier gas is H2, Column flow is set to 1.7

What is the DC Polarity listed on the sticker on the analyzer - is it Pos or Neg? Positive

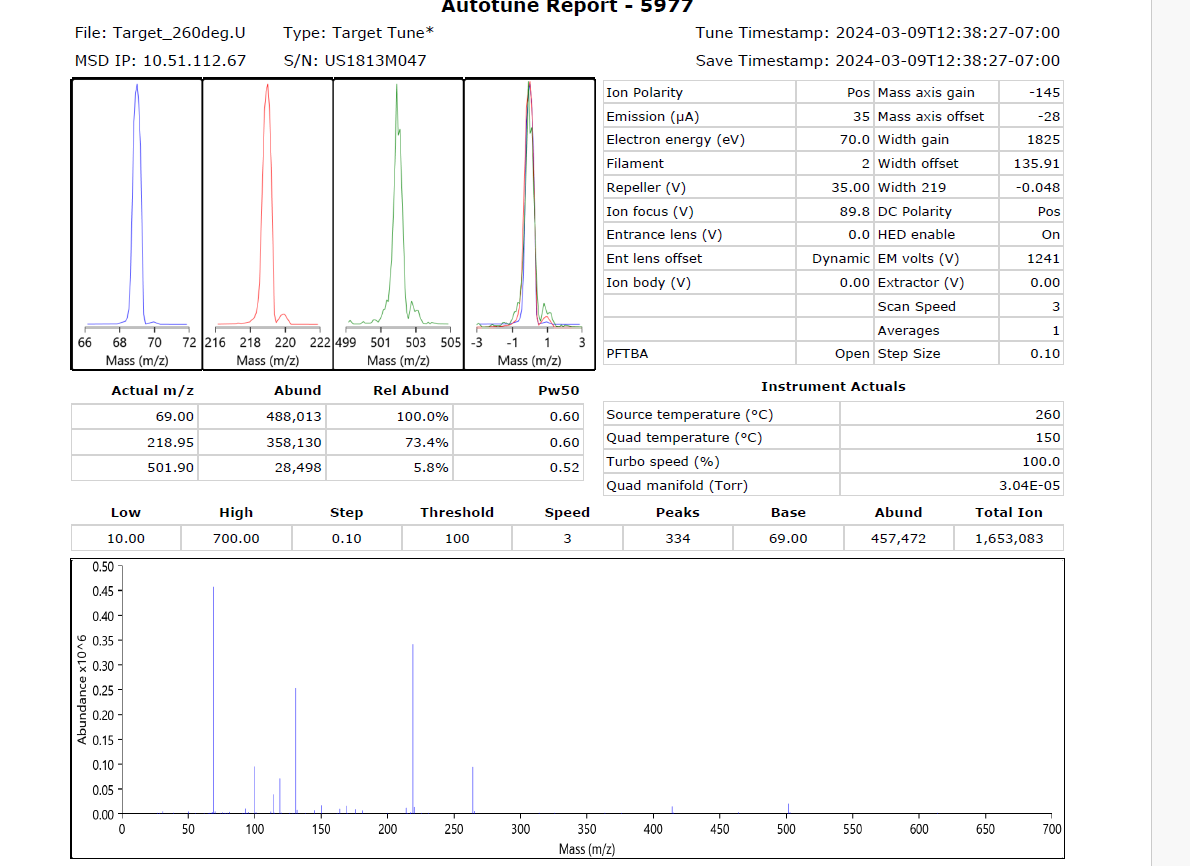

This tune file is from this morning, I'm just concerned with the noise seen before the 502 peak in the tune. Should it be a concerned? If so, what could be the cause?

Thank you so much!

Turn the hydrogen carrier gas flow down to 0.8 ml/min and try again.

1.7 ml/min of hydrogen is too much flow into the GCMS. While the maximum recommended hydrogen flow in the manuals is 2.00 ml/min, that does not mean the system will work properly at that flow rate. The optimum flow into the ion source is 1.2 ml/min of helium. There are so many more molecules of hydrogen at the same volume than helium that the recommendation for hydrogen is ~ 60% that of helium - so 0.72 ml/min.

There are 353 peaks in your tune spectrum. This is high but not unusual running hydrogen carrier gas and certainly not unusual at too high column flow rate.

All troubleshooting is done using ATUNE or ETUNE tune reports as the way those algorithms work is standardized. Target Tunes can be changed.

Please turn the column flow down to 0.8 ml/min and share an autotune report. You may have too large of a column installed to be able to get the flow that low and still have the recommended >5.0 psi inlet pressure at your oven initial temperature. Please explore using a 20m x 0.18 mmid column when using hydrogen carrier gas.

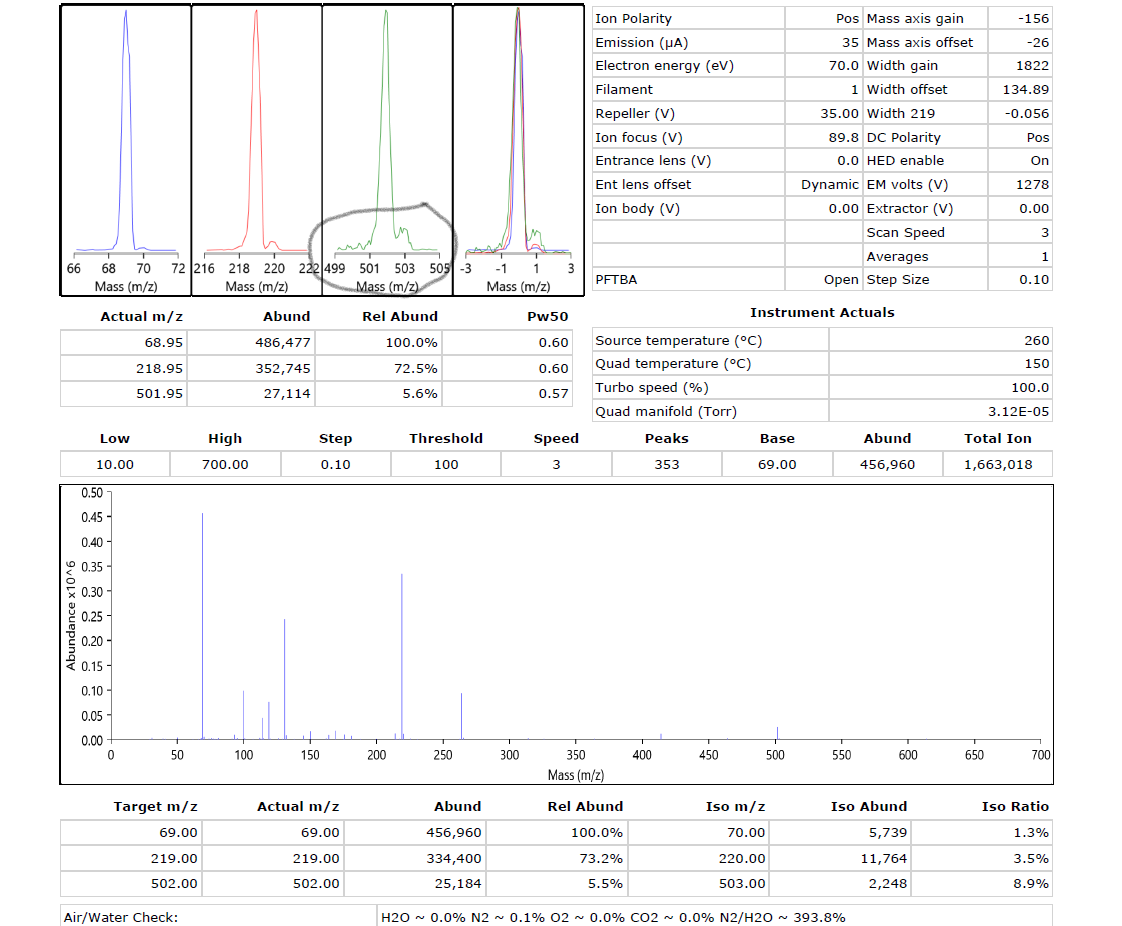

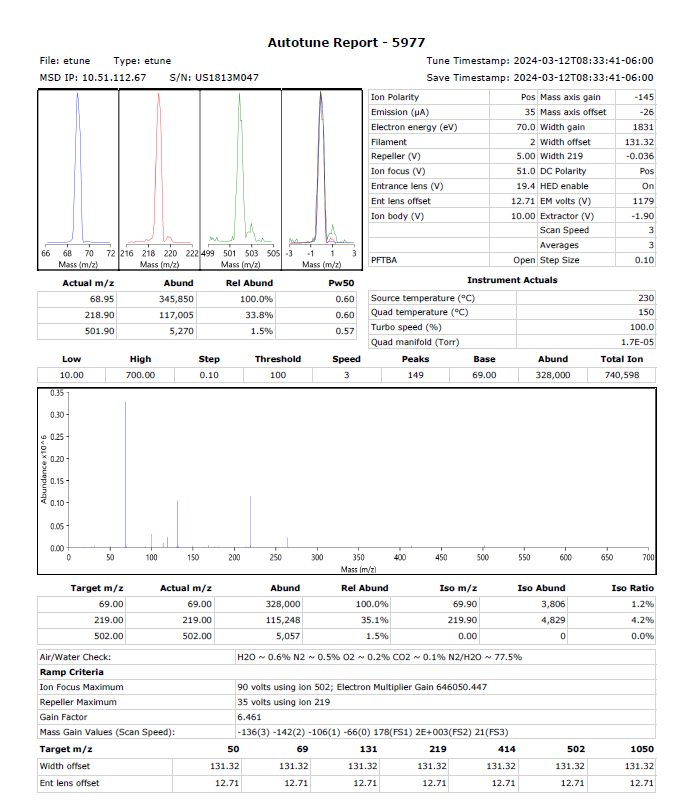

Hi, I changed my flow rate to 0.9ml/min in order to have meet the recommended >5.0 psi inlet pressure. I attached the etune below. I do want to mention that we have a hydrogen inert source since we are using hydrogen gas.

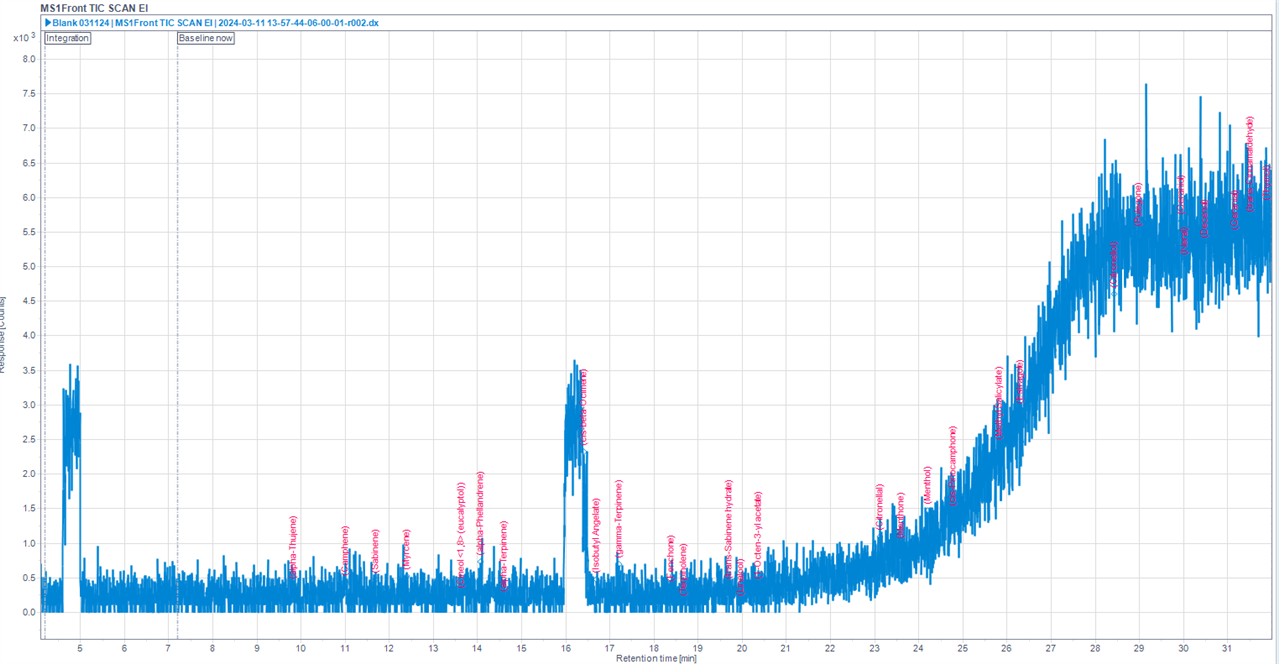

I do want to mention that I ran some blanks (just DCM) yesterday and I'm now starting to see a baseline drift in my blanks. See the image after the tune file. The baseline drift is appearing in my samples as well.

The hydroinert ion source uses a 9mm extractor lens, so the tune is going to be different/lower than typical 3mm extractor. The tune ion peak shapes are better with the lower flow rate, but 219 and 502 are both quite low relative to the 69. The hydroinert ion source cannot be abrasively cleaned. I would suggest baking it out at 325° C for some hours, three or five, let it go back to 230° C for an hour, and tune again at this proper flow rate.

Total Ion Chromatogram going up over time with oven temperature is GC related, not MS. There are many data points before 21 minutes that show 0 abundance. What is your acquisition gain setting, electron multiplier voltage, and threshold? What is a spectrum of the noise at 7 or so minutes compared to the baseline at 29 or so minutes? I would guess that this is typical column bleed at 207 amu.... What type of column is installed? What inlet, flow, and oven setpoints?

I'd avoid using dichloromethane as solvent with hydrogen carrier if possible. At high inlet temperatures, it can react with the H2 carrier and create HCl. Our GCMS Hydrogen Conversion guide (Agilent EI GC/MS Instrument Helium to Hydrogen Carrier Gas Conversion) notes this can happen when inlet temperature is above 280 C - see page 34.