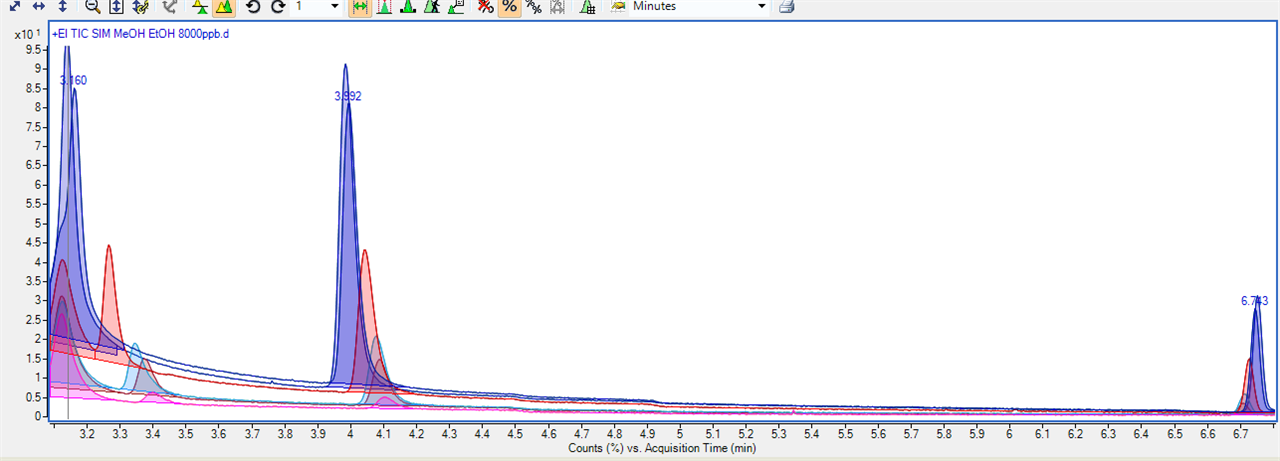

Hello everyone, I am working on GC/MS (8890 GC-5977B MSD). I run Methanol (in CS2) by DB-WAX column but the retention time of MeOH seem to be changed when I adjusted the injected volume 0,1; 0,2; 0,5; 1; 5 µL(other parameters still the same). Can somebody explain that phenomenon? Thank you for your help.