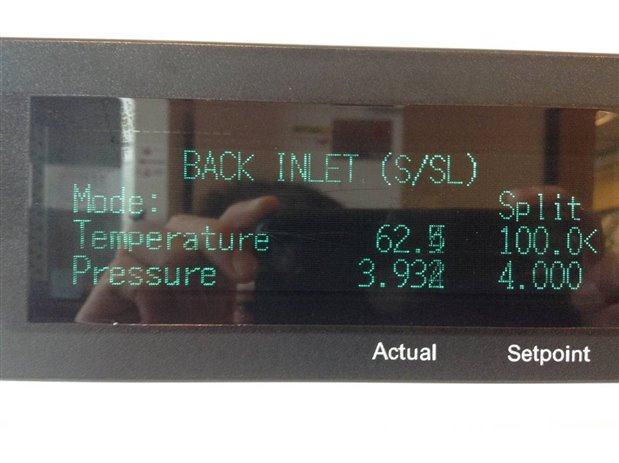

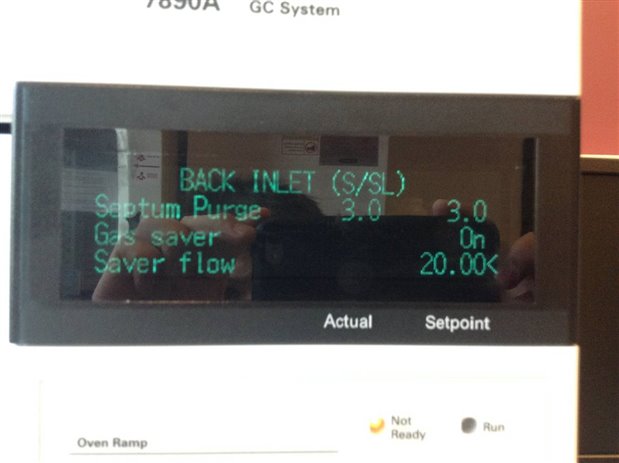

I have an Agilent 7890A GC-FID with dual split/splitless inlets and detectors configured with a 0.53 mm ID capillary column. My instrument keeps giving me the message "front inlet pressure, system shutdown". The front inlet cannot maintain pressure and the unit shuts down. On start up the front inlet pressure does reach the setpoint (5.96 psi), albeit sluggishly, but a few seconds later the pressure drops off by about 1.5 psi until it reaches a certain point. Then the pressure begins to slowly increase again by 0.001 psi/sec but never attains the setpoint and I get the error message. I'm working in splitless mode with N2 carrier gas and gas saver on, but I've gotten the same problem in split mode. I switched the column to the back inlet and the problem arises there too.

Agilent technical support told me the symptoms present as a leak, but everything I've tried has been unsuccessful. I've replaced the inlet septum, liner, liner o-ring, gold seal and washer, graphite ferrule, and zeroed the pressure sensors. I also cleaned in and around the inlet with methanol. I checked all gas connections with an electronic leak detector and did not find any leaks. The worst case scenario is a bad EPC(s), and I'm hoping we don't have to replace that! Any suggestions or insights would be greatly appreciated. Is there something I'm missing here or haven't thought to rule out? This is my last effort before I result to an Agilent service call. Thanks!!!