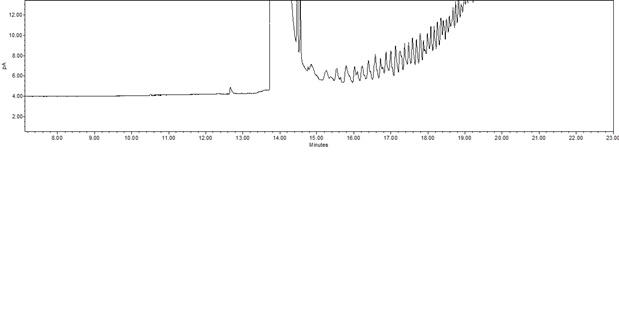

We have a baseline that gives a sinusoidal wave that starts about 16 minutes. We are using an Agilent 6850 GC with a split/splitless injector and an FID. The inlet is interfaced to a 7679A HS. The baseline is good up until 15.5 minutes then it starts the sinusoidal response. This response is consistent from one run to the next. We've baked the column per the manufacturer's instructions. We've re-installed the column on the detector end and put in a new inlet liner. Any ideas?