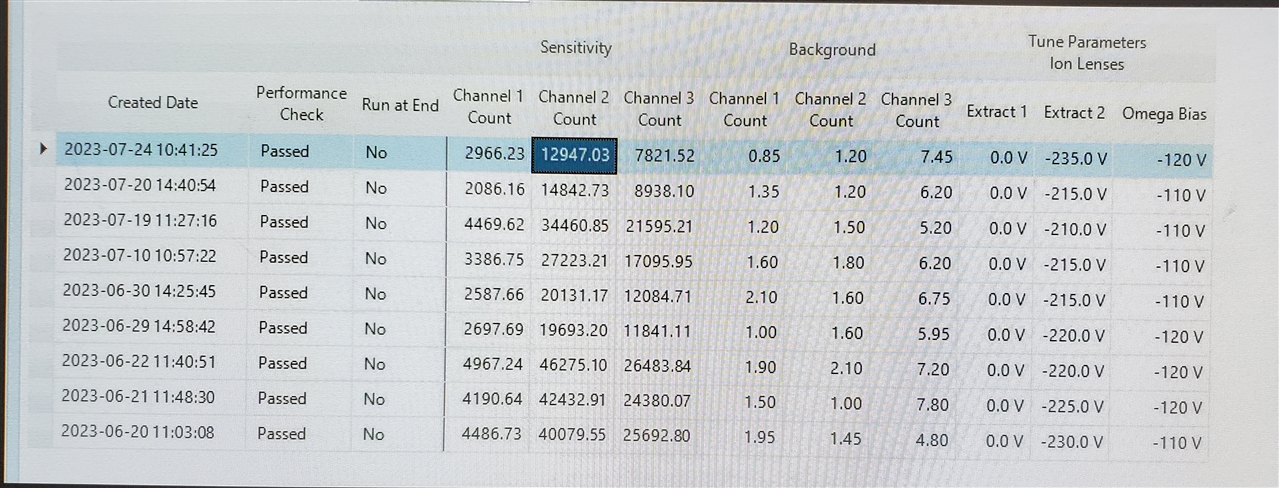

Is this level of variability in the 7/89/205 counts during plasma startup considered normal?

During install counts were as follows versus specification (converted to local units):

| m/z | Specification | Result |

| 7 | > 3,000 | 4,896 |

| 89 | > 15,000 | 34,144 |

| 205 | > 9,000 | 25,086 |

I'm attempting to set a requirement for routine testing but an unsure what's feasible given the variability. If it's not normal, how can I go about controlling this better?