Hi All,

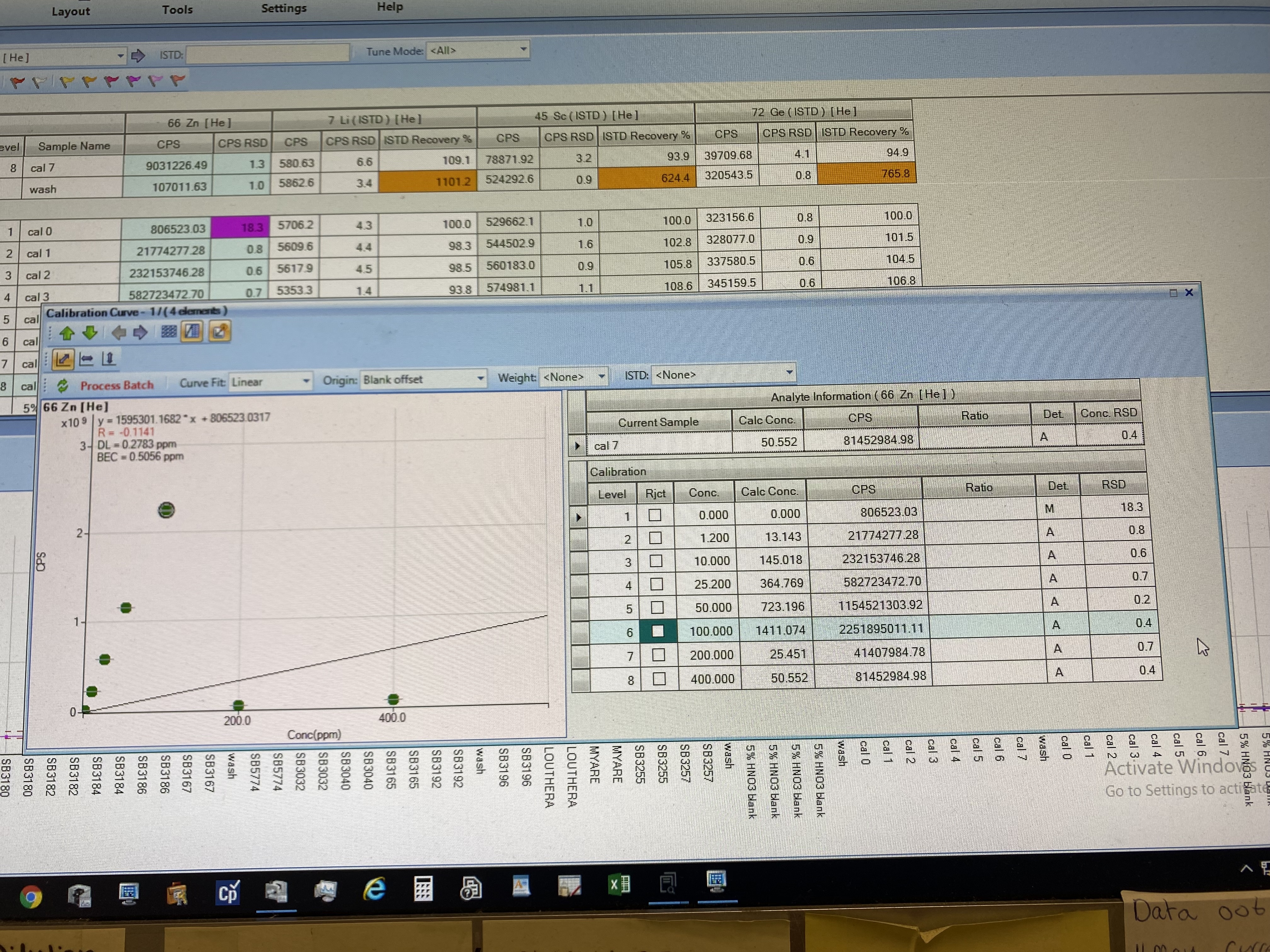

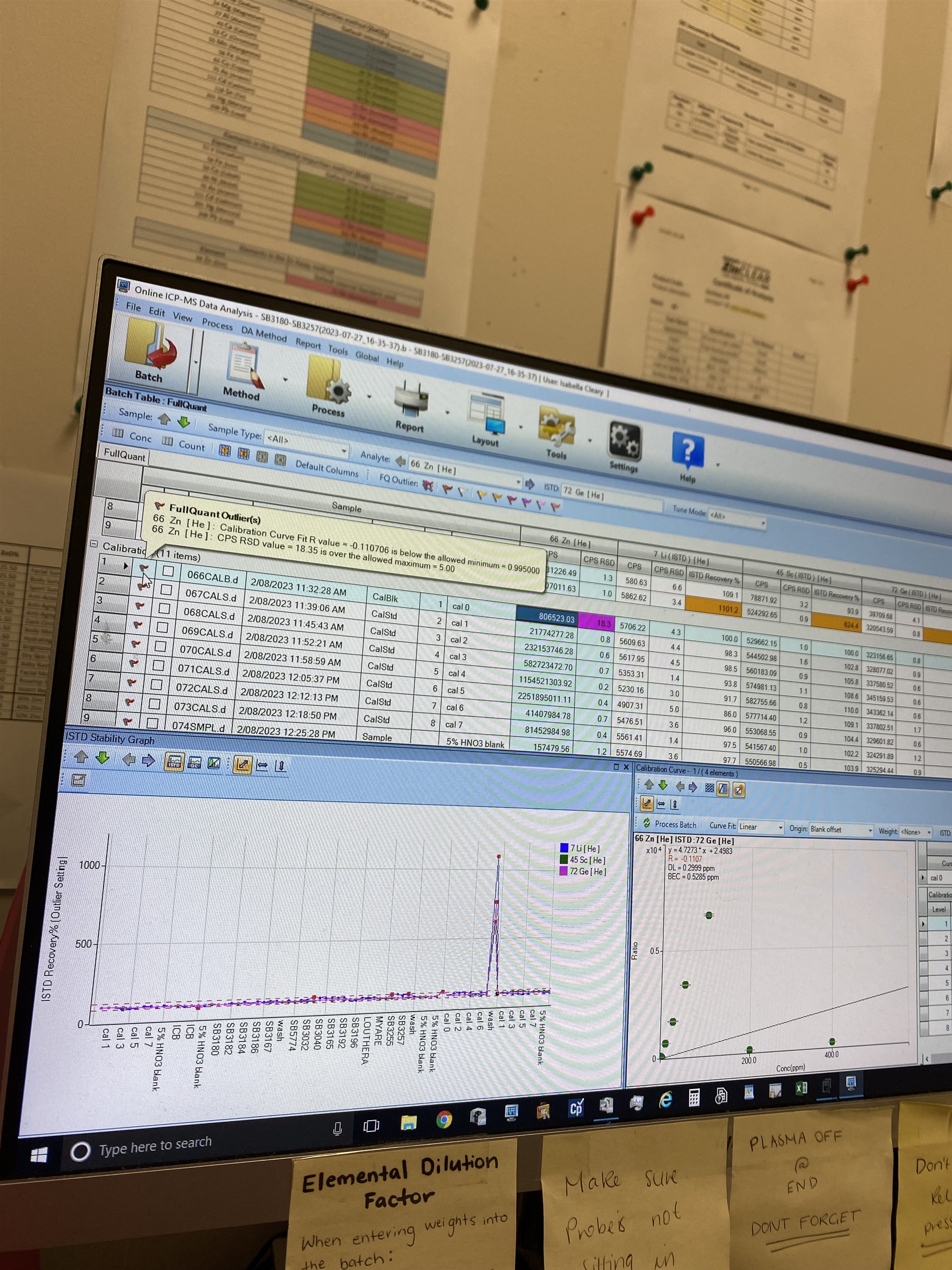

i have been having an issue with my ICP-MS software as my calibrations are coming back at a negative R value. this is despite full glassware changeover, tubing changed, fresh standards, and ITSD, and doing a thorough wash cycle.

the batch tune passes with good counts and RSD. any troubleshooting support to bring my R value to within range would be greatly appreciated.