We are having issues with the sample uptake rate on our SpectrAA 55 AAS unit. Apart from replacing parts, we have tried all the troubleshooting steps we can think of but can't get the uptake rate up past ~2.5mL/min, which is well below the required rate of 5-6mL/min. We used to be able to optimise a 10ppm Au solution to an absorbance of 0.36, but currently the maximum we are able to achieve is 0.2.

We have tried:

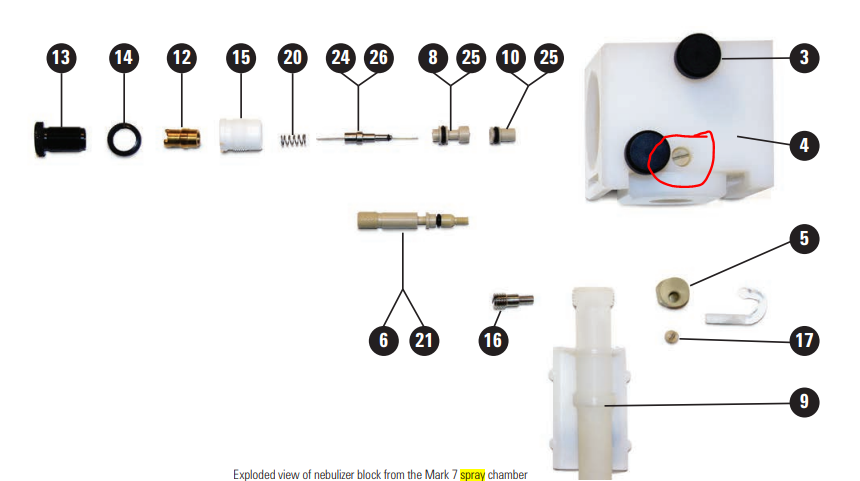

- Disassembling, cleaning and reassembling all the spray chamber components.

- Changing the capillary tubing.

- Cleaning the nebulizer with wire.

One thing I will note is that the thimble does seem a little loose fitting in the bush bearing. A slight movement can be felt when the thimble is wiggled when it is screwed in.

Before I go ahead and order replacement parts for everything, is there anything else I should be trying, or any specific part that is most likely to be at fault?

Appreciate your knowledge and advice.