Hi All,

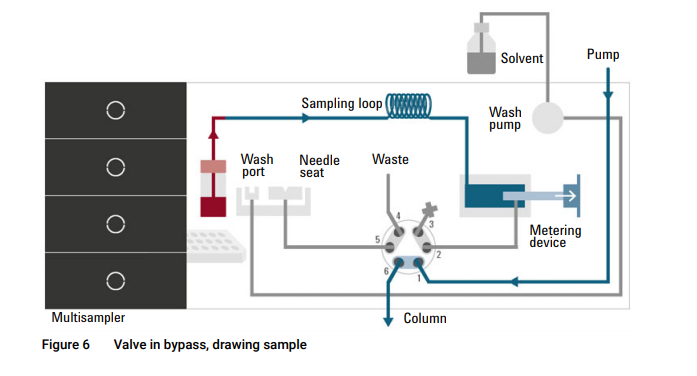

My goal is to make the autosampler dilute our sample by 30 times (possibly more) before injecting 1ul, preferably without mixing in a separate vial. The reason being that we have very low (~1ng/ml) and very high (~2mg/ml) concentrations of some compounds in our samples. I have tried deoptimizing the high concentration compounds and that didnt work because they were still overloading the column.

Normal injection volume without injection program (to get low concentration compounds) is 3ul. We have a 20ul injection loop installed.

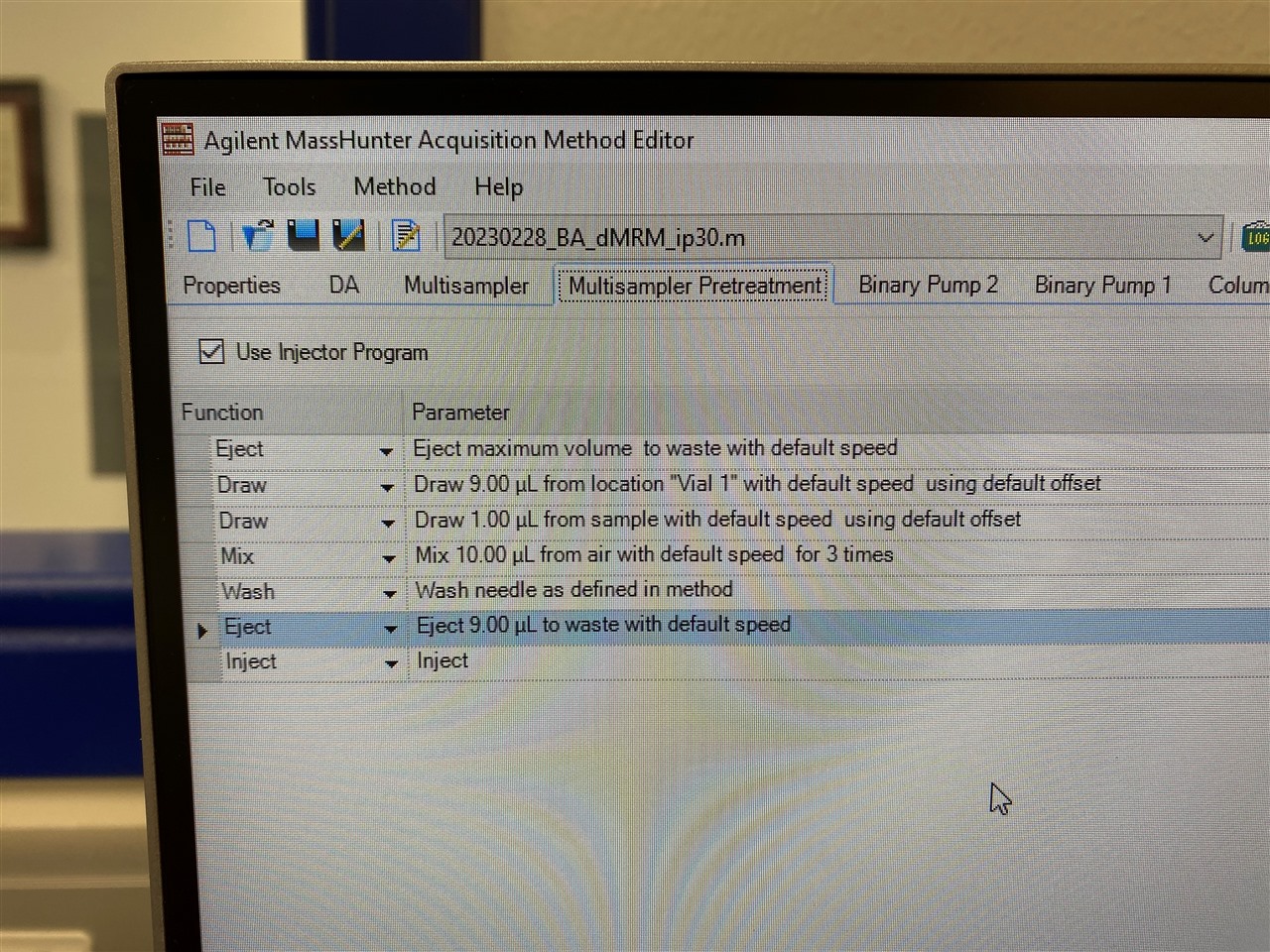

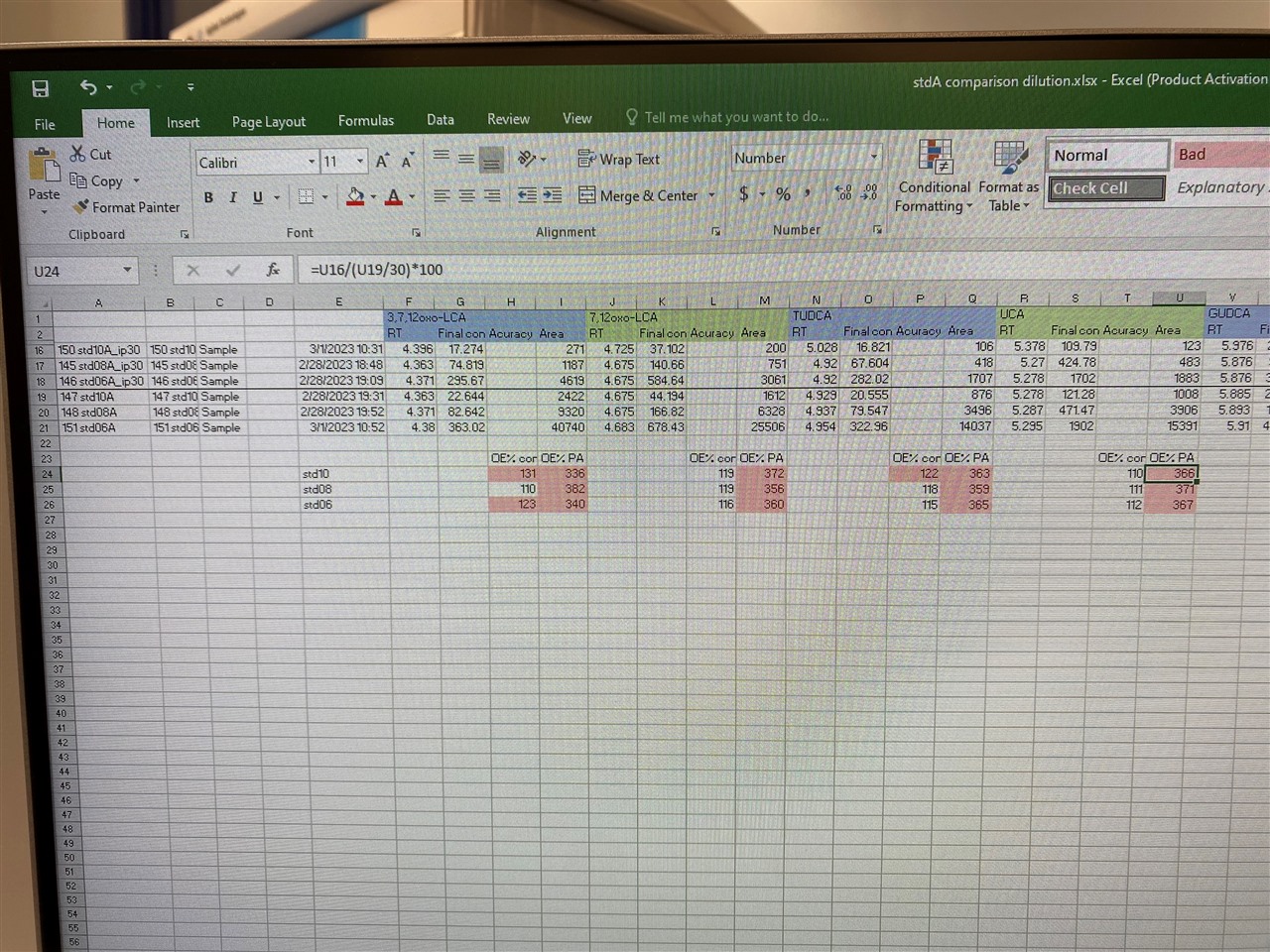

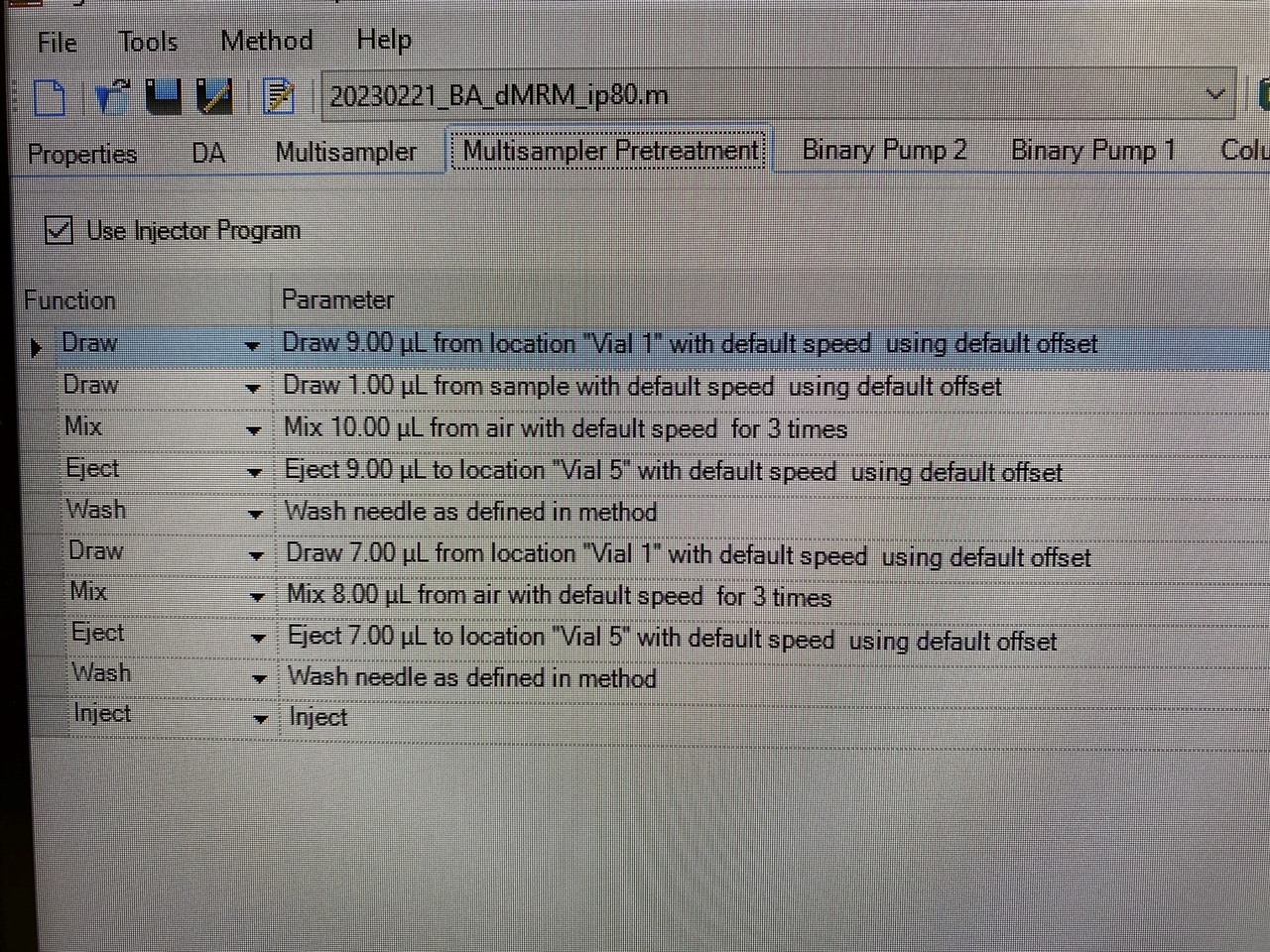

The injection program we are trying to use for 30x dilution is pictured below, idea being that if there is only 1ul of the diluted mixture left in the needle, it will inject that amount at the inject step. Methanol with a preslit septa is in vial 1 position, and an empty vial with no cap is our waste vial in vial 5 position. The injection volume on "multisampler" tab was automatically(?) changed to 20ul. The peak areas of standards run with this injector program are 900% observed to expected ratios consistently compared to the same standards run without the injector program.

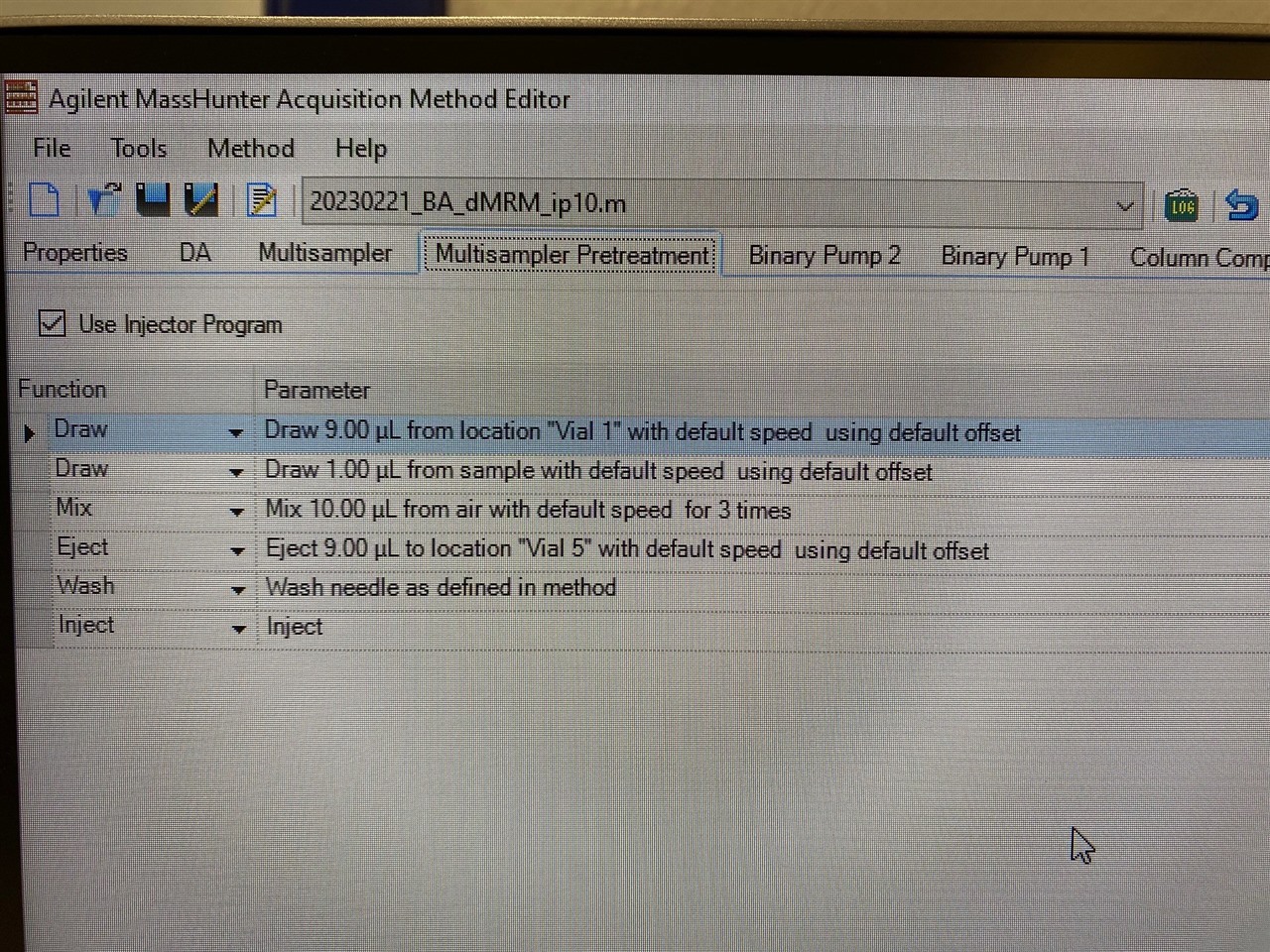

I also tried the program pictured below to dilute by 240x. When I tried changing the injection volume back to 1ul on the "multisampler" tab, the method errored at the second mixing step saying something along the lines of volume of the sample loop was exceeded. setting the injection volume back to 20ul allowed the program to run.

My main question is, what volume is injected when using an injector program? The volume left in the loop? or the volume specified in the "multisampler" tab. Also where does it go wrong with getting a 30x and 240x dilution?

I have seen other solutions that involve diluting and mixing in a separate vial prior to injecting, but we really want to avoid that if possible.

Also please note: injecting only 1ul of undiluted standards does give 1/3 peak areas of 3ul injection.