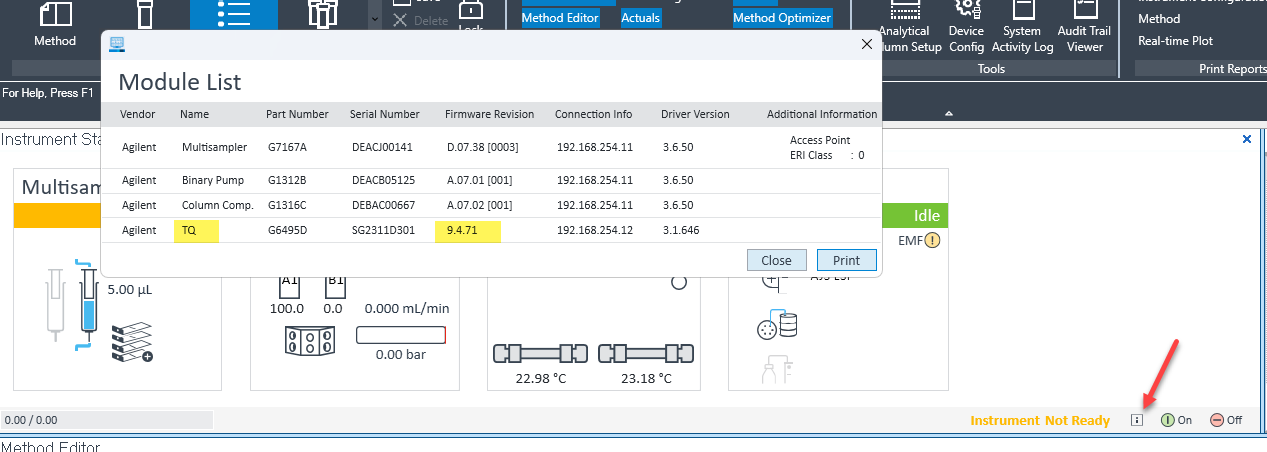

I have noticed recently that on hot afternoons, the triple quad computer doesn't recognize the temperature settings for the drying and sheath gasses (set to 200 C, flow rate of 10 L/min). Instead of abiding the setting, the temperature for both gasses increases until around 395C before throwing a drying gas flow fault error (zone controller cannot regulate for requested setting). I believe the software thinks the temperature has been set this high, as hovering over the TQ icon shows that the desired range is between 395 and 400C despite the settings for both gasses being at 200C. I can prevent the error by turning the TQ off and allowing the temperature to settle back down to 225 and 150 C for the drying and sheath gasses respectively. This, however, does not change the discrepancy between the set and resulting temperatures. There are times that resending the method to the instrument fixes this, but on the hottest days nothing will get the quad to listen. I managed to run some samples by starting the worklist before the instrument readied (standby at 225 and 150C). Doing this finally got through to the TQ computer as the temperature began decreasing and eventually equilibrated at 200 C.

I've been able to evade this issue and run samples, but it seems like a Band-Aid fix. I was wondering if anyone else has experienced this and knows if it could be temperature related. I know that the temperature by the MS is within operating range, but I only seem to have this issue on hot days in the afternoon.