Hello,

I have set the temperatures to the minimum, but when I put the QQQ on standby, the temperatures rise again. If I open the spray chamber, I receive an error/fault message stating that the source is open. The gas continues to flow, and I cannot set it to zero. Is this expected?

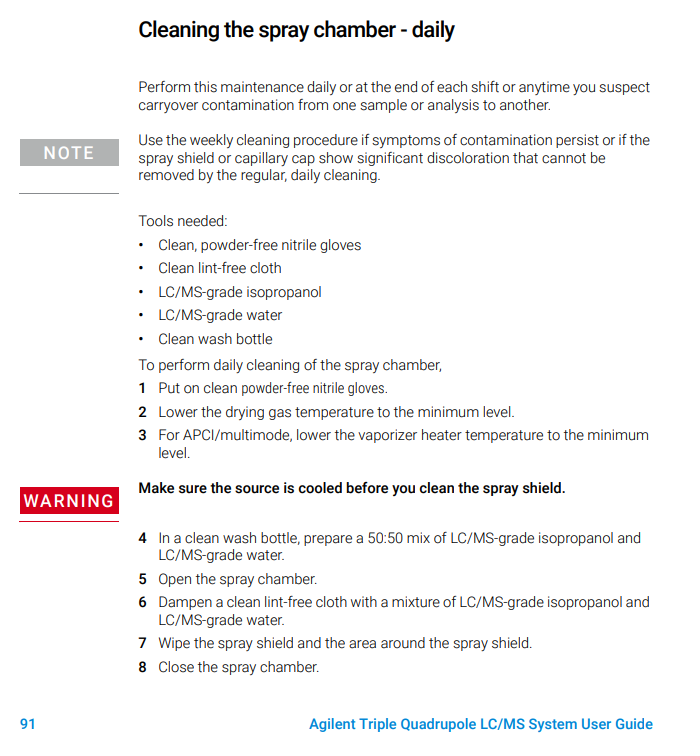

I have consulted the resources from Agilent on how to clean the spray chamber, but they don't provide enough details, and I am not confident in how to do it.

Could you please refer me to a more detailed procedure or give me advice on how to clean the spray chamber?

Thank you!

Best,

Karina