Hi,

I am currently encountering coeluted peaks in my chromatographic analysis for two specific analytes following a recent maintenance session. To provide a comprehensive overview, here is a detailed timeline of the actions taken:

- Prep MPA (0.1 % formic acid aq) and MPB (0.05% formic acid aq)

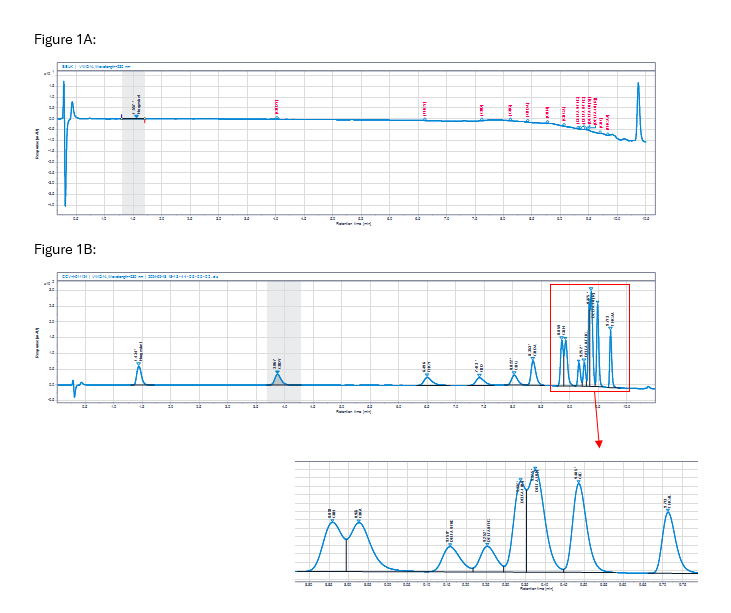

--> ran a blank (MeOH) [Figure 1A] and system stability check of a Continuing Calibration Verification Standard [Figure 1B].The chromatography of this run mirrors our normal results

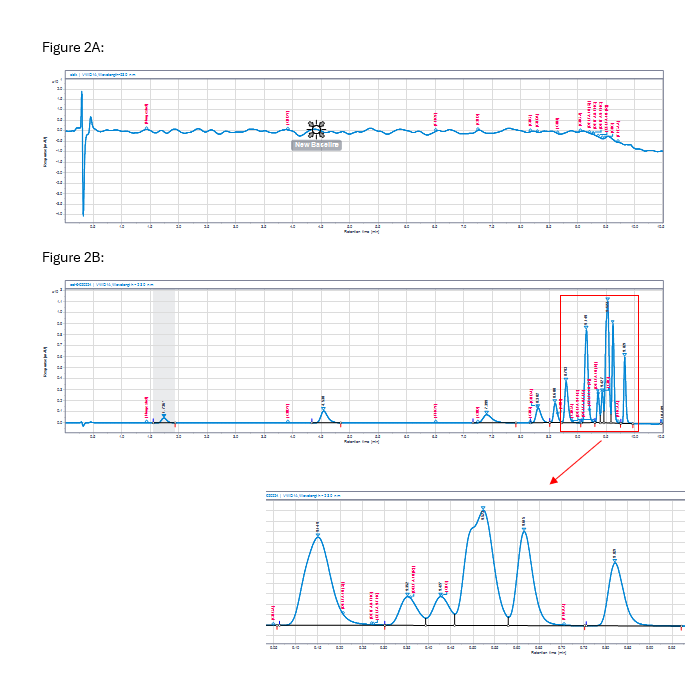

- Same day: Following the calibration run, the chromatogram reveals RT shifts and coeluted peaks

--> blank (MeOH) [figure 2A] and a calibration level [figure 2B]

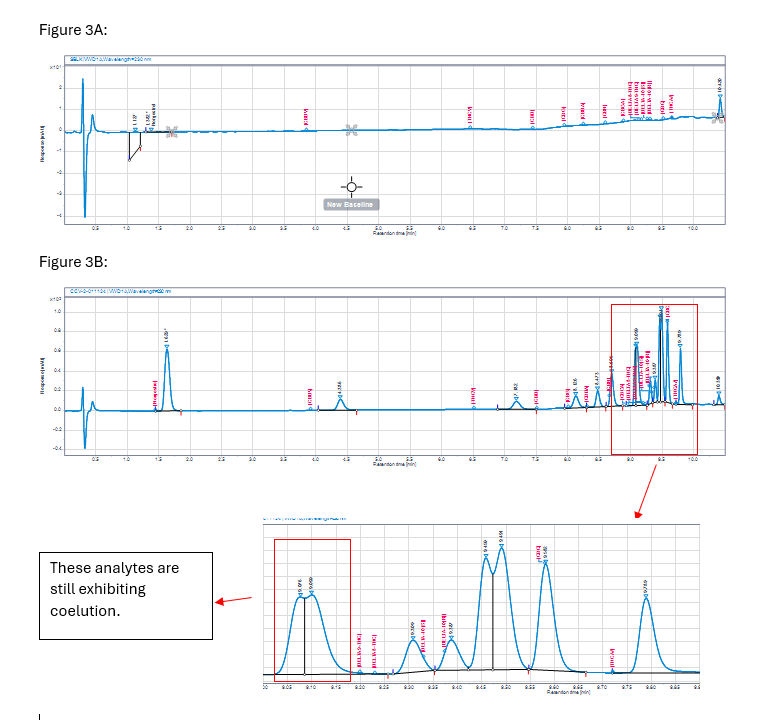

- Replace the guard column, ran a blank (MeOH) [figure 3A] and a calibration level [figure 3B]

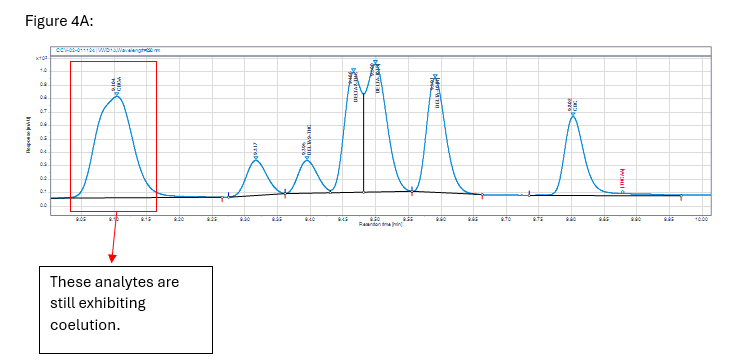

- Replace guard column and analytical column [Figure 4A]

Any ideas on how I can fix this issue?