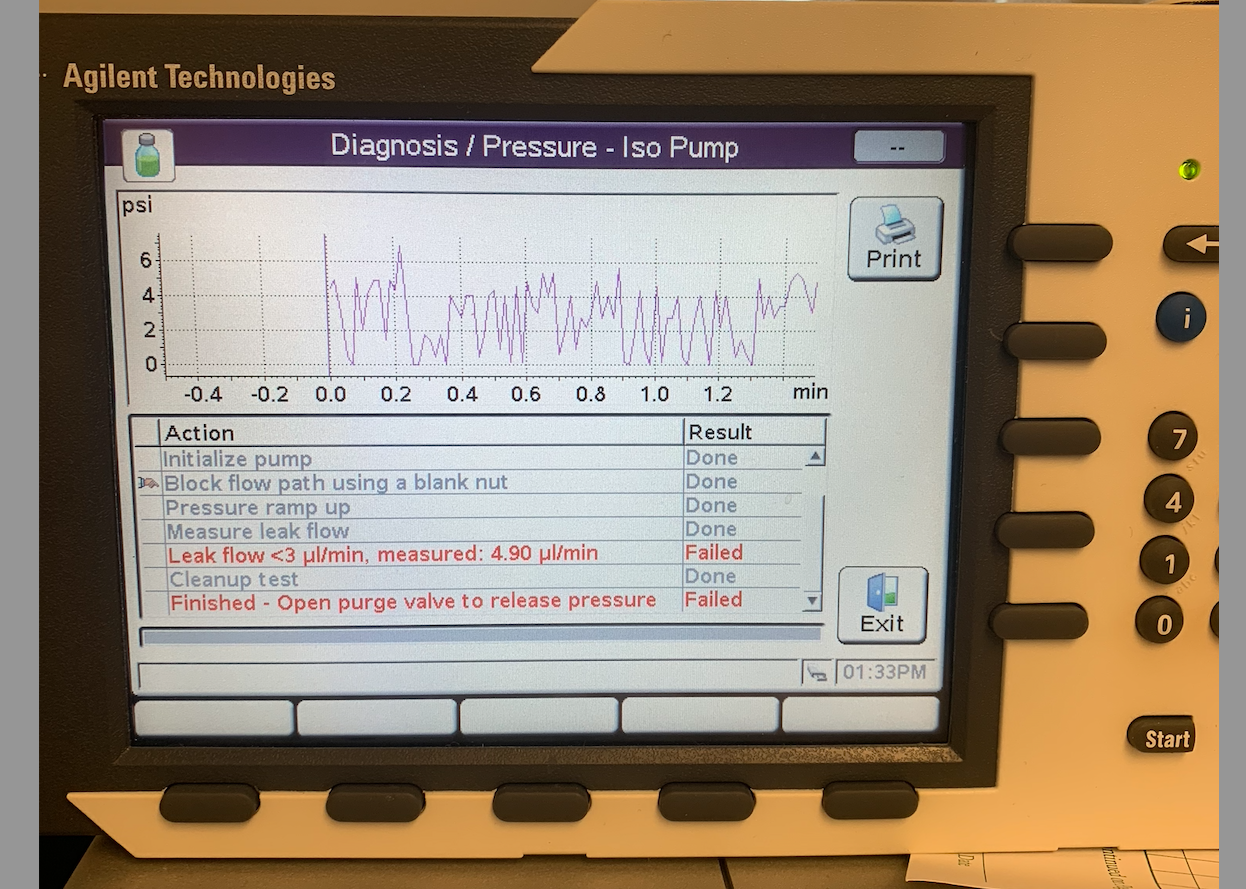

Hello. We have issues with the 1260 infinity binary pump (1260 iso pump, G1310B). It is a DMF GPC-MALS system. We are currently washing the whole system using ACS Certified DMF, and the column is not involved now. DMF goes through the degasser (1200 series, G1322A) first and then goes into the pump. There are 4 channels in the degasser. DMF can go through channels A, B, and C but cannot go from D to the pump. We are pretty sure the degasser is functioning well. We ran a diagnosis of the pump and it says the pump is leaking as the picture shows. What can we do to fix the pump?