Greetings,

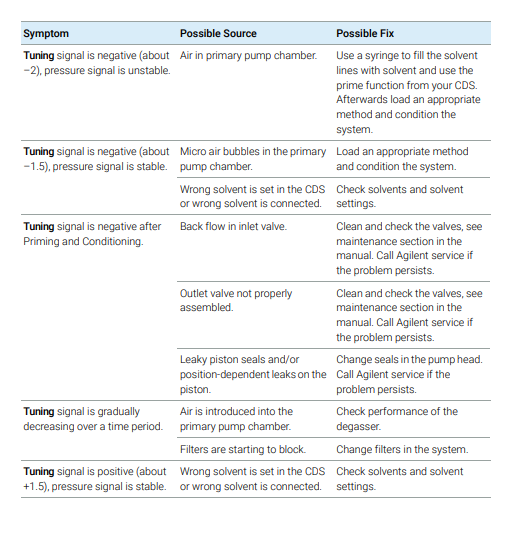

I am trying to determine whether or not my binary pump is working properly. I have heard three different opinions with respect to the tuning parameter. This post ( RE: Tuning A and Tuning B parameters in Binary Pump of 1290 LC ) indicates that +/-1 is acceptable. However, I have also heard +/-0.4 from an Agilent trainer, and +/-0.2 from my service technician.

For my system, the tuning parameter for Pump A typically stays below 0.1, but pump B can vary from 0.05 to 0.2. However, lately the tuning parameters for both pumps have been drifting upward, sometimes as high as between 0.15 and 0.2. According to my service tech's opinion above, this is brushing against the upper limit for acceptability.

My questions for the community are:

- How do I interpret what is going on? I don't have any other indication of error (e.g., leak, pressure fluctuations)

- What at what point do I really need to worry about the pump tuning parameter? Is it even something that I should bother monitoring?

- Would running a conditioning routine for the binary pump have any effect?

- How is conditioning different from, say, running at a high flow rate for ~15 minutes? I ask this because I am experiencing difficulty executing a conditioning routine in MH Acquisition from the "prepare pump" menu (nothing happens).

Any insight would be greatly appreciated. Thank you!

Mike