We are struggling with an issue where our mobile phase will not *actually* change composition during a gradient when going from a more viscous solvent to a less viscous one (H2O to acetonitrile, for instance). The instrument says it should be changing, but the pressure reading does not change and our chromatographic results indicate that it is not truly increasing the amount of ACN in an H2O/ACN gradient. This began happening after a user mistakenly didn't have their worklist run the shutdown sequence at the end and the ACN bottle ran dry while unattended.

We ran a purge right away to fill the lines again, and then noticed that it needed to be primed also as there seemed to be some air in the pump somewhere. We ran an injection thinking things were alright and nothing much eluted from the column (or just did so very abnormally). What we realized is that we were running -- in reality -- an aqueous isocratic separation because the pump was not really introducing ACN into the mobile phase. The mobile phase pressure was very steady, until the point where the gradient got to 95% ACN and then it had a little blip and lots of small spikes, but no real change in the pressure away from a typical pressure for high H2O fraction on this particular column (~400 bar). So we deduced that ACN is not actually getting into the column.

Ran a prime sequence to see if there were more bubbles. At the end, I had it set so that the mobile phase would be 100% ACN when the prime ended. At this point, the pressure looked like what we would expect for 100% ACN (~130 bar). So then to test, I stepped the mobile phase ratio from 95% ACN down to 5% ACN in a few jumps. At or below 50% ACN, the pressure went straight to what would be expected for mostly H2O present in the column. So I can prime the pump and get ACN to flow, but as soon as I add a bunch of water, ACN stops flowing and the pump only ends up pulling on the H2O bottle. This 'priming' tests is highly reproducible, done it many times in an attempt to dislodge a bubble or just see if it might eventually behave.

Called Agilent support, they suggested doing the same with IPA to help dislodge bubbles if there were any. Also cracked open the inlet and outlet valves on the pump to bleed some liquid out and any air along with it - upon suggestion. The IPA seemed to work better and behave more like the instrument should normally.

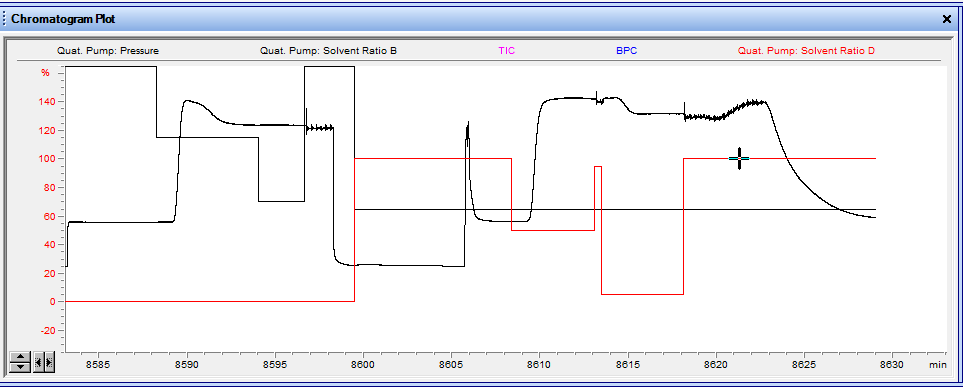

Went back to using ACN as the organic to test my real method case. All of the odd behavior came back. Phone support suggested changing to Channel D (was using B) to see if it helps. It did not. Pasted below is a screenshot of my testing today, first with ACN on channel B and then with the same ACN bottle on Channel D instead.

So here's my little test protocol (with column installed):

1. 100% ACN, ensure I'm getting the lower pressure that is typical for high %ACN

2. 50% ACN

3. 5% ACN

4. 100% ACN

If the pressure doesn't decrease when going back to 100% ACN, the test fails as ACN is not being introduced.

And something odd started happening later in this process (been a few solid whole work days running tests and troubleshooting), if I leave the system alone for a while after going back to 100% ACN at the end of one of my tests, the pump eventually starts pushing ACN again and the pressure drops -- this is seen in the second round of my test shown below. This behavior is also reproducible, at least for the latter part of my testing.

In the figure below the first round is with ACN in channel B (black solvent ratio trace). Then I switched bottles around 8600 min, ran a purge for channel D and repeated the test. The blip at 8613 min is just me mistakenly putting in the wrong number for a second for %D. After changing the system back to 100% ACN around 8619 min, I did not touch anything. That's all just happening on its own, and that behavior is reproducible.

Sorry if this is a little rambling an repetitive -- I'm just looking to see if anyone has seen this behavior before and has an idea of what might cause the issue. Next step is a service visit and a bunch more down time when I really need to not have down time...

Thanks,

Doug