안녕하세요.

저는 현재 gc-ms 헤드스페이스를 사용하여 분석하고 있습니다.

저는 메탄올에 희석한 표준 용액의 고정된 양을 10mL 증류수 바이알에 첨가하고 있습니다.

여기에 몇 가지 질문이 있습니다.

1. 용매 지연은 메탄올이나 증류수를 말하는 것인가요?

2. SIM 방법에서 용매의 이온 값을 입력하지 않았는데도 용매 피크가 나타나는 이유는 무엇인가요?

3. 용매와 대상( 염화비닐) 물질의 머무름 시간이 겹칩니다. 용매를 더 빨리 용출(또는 분리)할 방법이 있나요? (RT 1.4분)

4. 겹치는 물질이 용매가 아니라면 무엇이 문제일까요? 공백에도 같은 피크 면적이 나타납니다.

귀하의 답변을 부탁드립니다.

감사합니다.

/ oven

| ℃/min | next ℃ | hold time |

| 35 | 4 | |

| 10 | 230 | 1.5 |

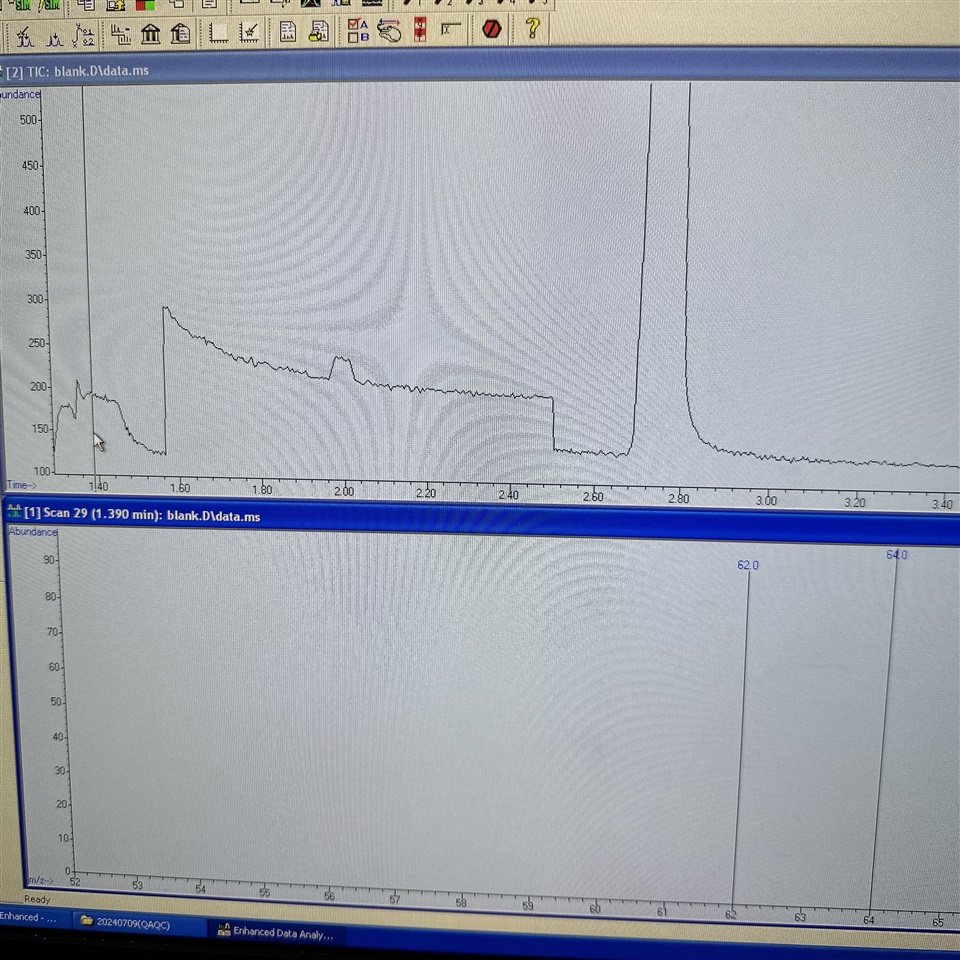

- 공백 스펙트럼

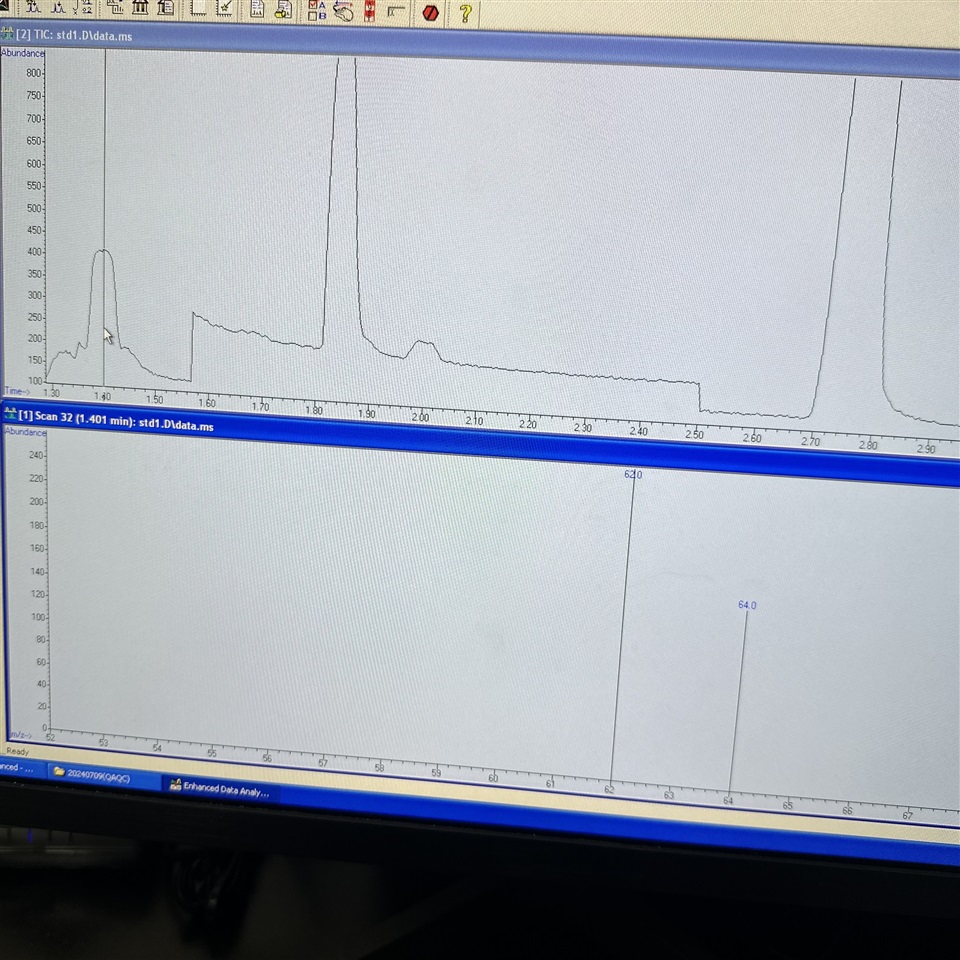

- std1 스펙트럼

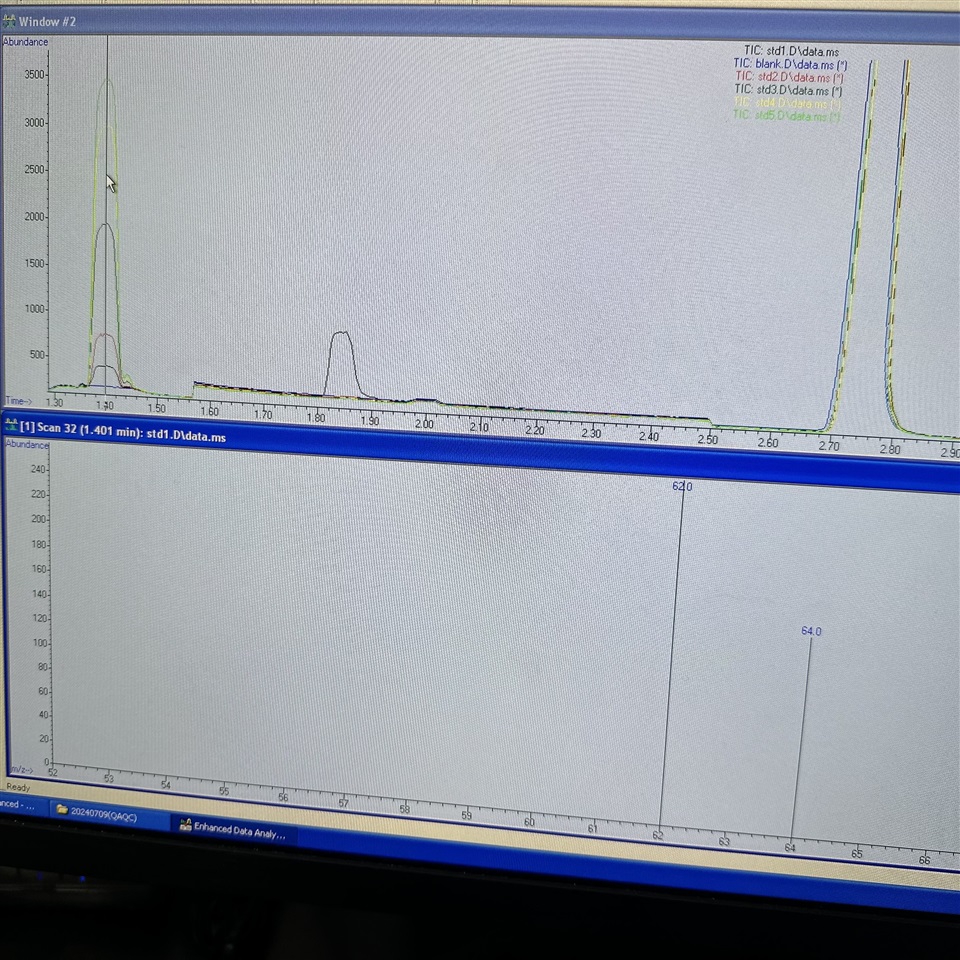

- 빈칸 + 표준 오버레이 스펙트럼