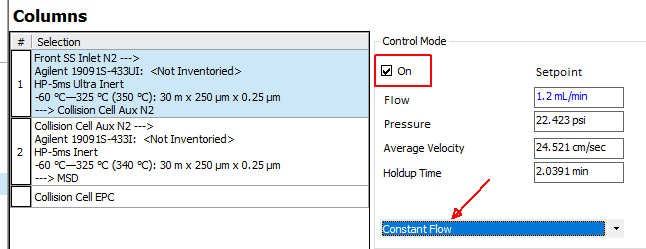

Instrument: 7890B Agilent GC & 7010B TQMS

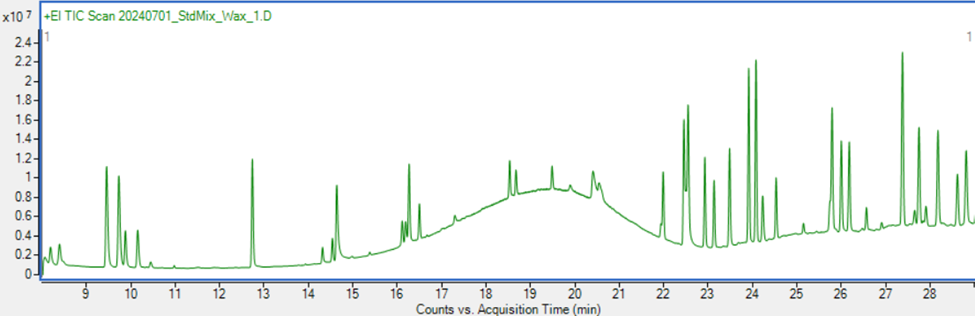

Hello, our issue started when we noticed a giant peak on a DB-Wax column in the front inlet – it has ions indicative of ethyl ether, which we often use as the solvent in our injections and was injected with the sample that this chromatogram is representing, however, we typically never see the solvent, as it disappears in the solvent delay. Before this front inlet run took place, we ran DHS on our back inlet with the same column, and the chromatogram looked normal with no large peak. There was no solvent in the DHS run, but this proved to us that it likely wasn’t a column or detector issue.

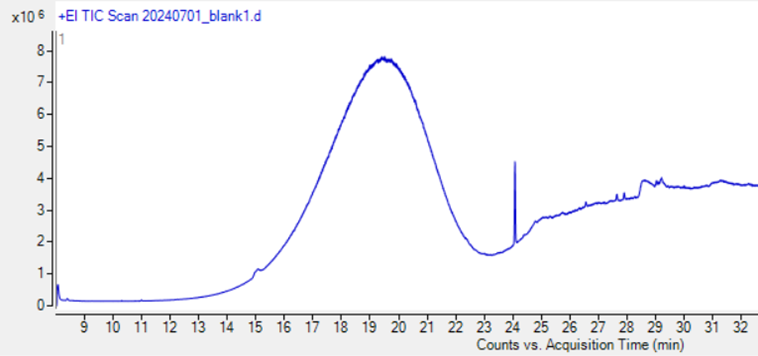

Sample with giant peak (sample was a mix of ~45 flavor standards in diethyl ether solvent), this was a splitless injection on a DB-Wax column and the method has been used previously with no issues:

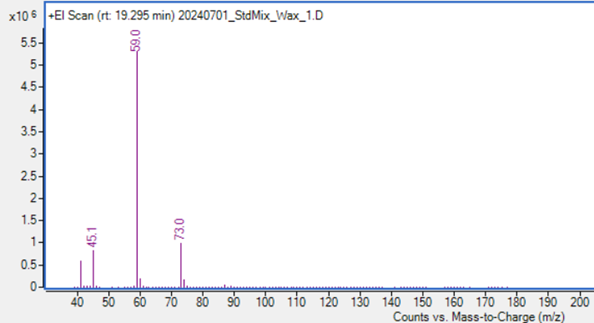

Mass spectrum of giant peak - looks like ethyl ether:

We ran an air blank (remove solvent from the equation) and the giant peak was still present.

Air blank on DB-Wax (syringe was on and wash station had ethyl ether as it normally does):

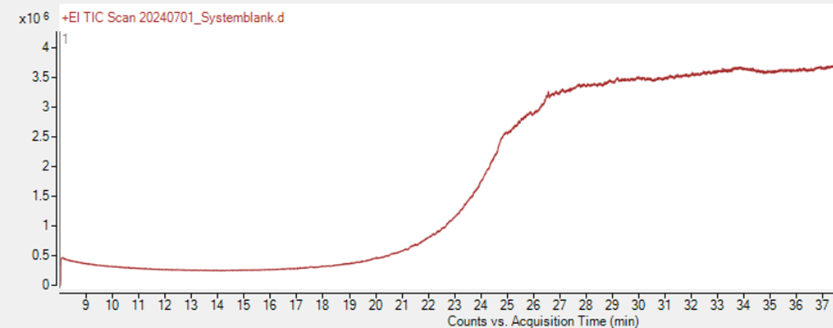

We ran a system blank (ran the same method but removed the injection syringe) and the giant peak disappeared, the baseline looked normal.

System blank on DB-Wax (no syringe):

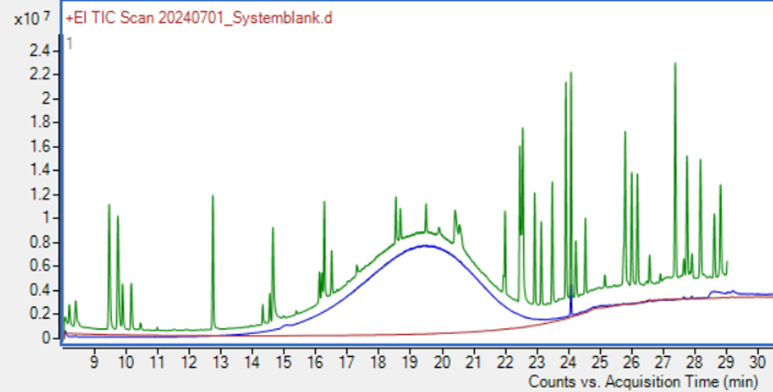

Overlay of the 3 chromatograms:

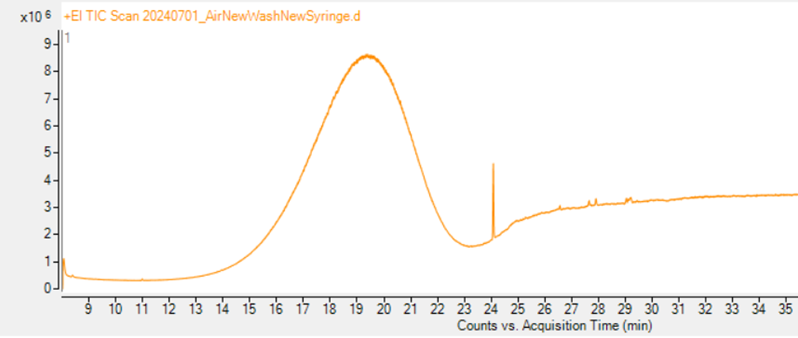

At this point, we thought the syringe or wash station bottles could be contributing to the issue, so we changed those out with new parts + solvent (which is ethyl ether) and ran another air blank. We also put in a new liner and septum just in case something was going on with our current ones, though they looked visibly fine. The giant peak was still present.

Air blank with new liner, septum, wash station, and syringe:

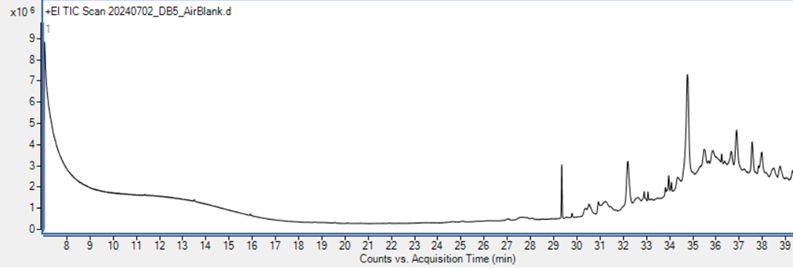

At this point, we swapped to a DB-5 column (that we know is in good condition) because we thought maybe something might be wrong with the DB-Wax column. We ran an air blank after installing the new column and there is still an elevated baseline due to the solvent peak…though we are not injecting any solvent into the system (aside from washing the syringe at the wash station). We have run the same method many times before and never have had this type of issue. To note, this issue is reproducible, we ran the air blank twice and the chromatograms overlay almost perfectly.

Air blank on DB-5 column:

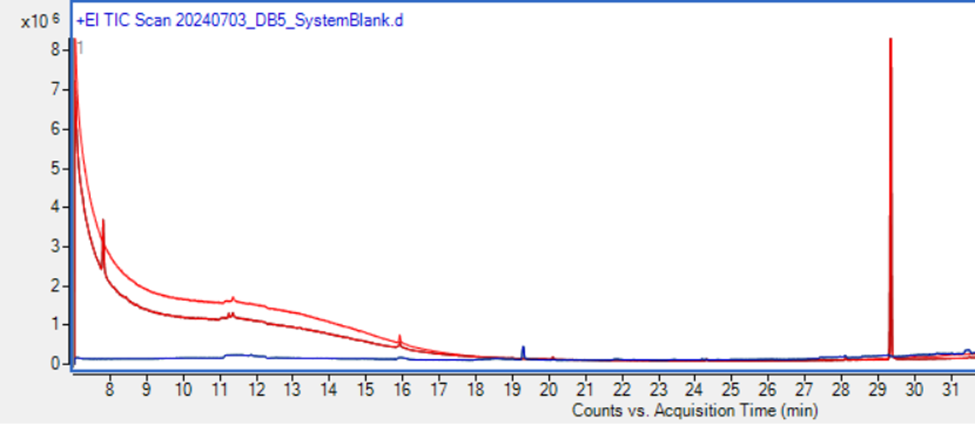

After calling Agilent, we checked the gold seal (looks completely fine) and the attempted the clean the channel that leads to the split vent line with solvent- it was clean. We ran an ethyl ether solvent blank, an air blank, and a system blank after performing these actions. The system blank looks normal, while the solvent and air blanks have the giant peak.

Chromatogram overlay (DB-5) of ether solvent blank, air blank, and system blank after cleaning/checking gold seal and solvent vent line (the system blank is the blue line):

The only thing in the front inlet that we have not replaced (that we can think of) is the split vent filter cartridge, but we have just ordered parts to do so. Could this be the issue? Is there something else that we are missing or that might be worth trying?

Note: The only thing that happened in the time span between functioning instrument and giant peak was that various solvent mixtures were run on the front inlet. Testing extraction solvents, someone was running DCM/ether, hexane/ether, DCM/hexane on a DB-Wax column – there may have been some water in the samples (we are not sure), but likely not much.

Tune: The tune looks like previous tunes and nothing is out of the ordinary (normal air/water levels)

Any help you can offer would be greatly appreciated, thanks!