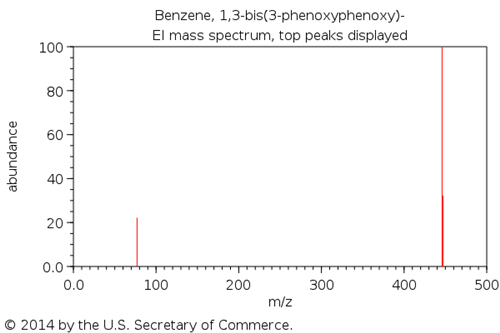

After some very severe foreline pump backflushing into an MS, our thermal desorption-GC/MS system has shown noisy high background chromatograms - not surprising. Looking at the ions, they are generally spaced by 14 amu which seems to be indicative of foreline pump oil.

I have cleaned the ion source thoroughly and wiped off the large inner surfaces of the MSD with methylene chloride, but the background is still there and has not diminished even slightly. Baking out the system has not worked out either.

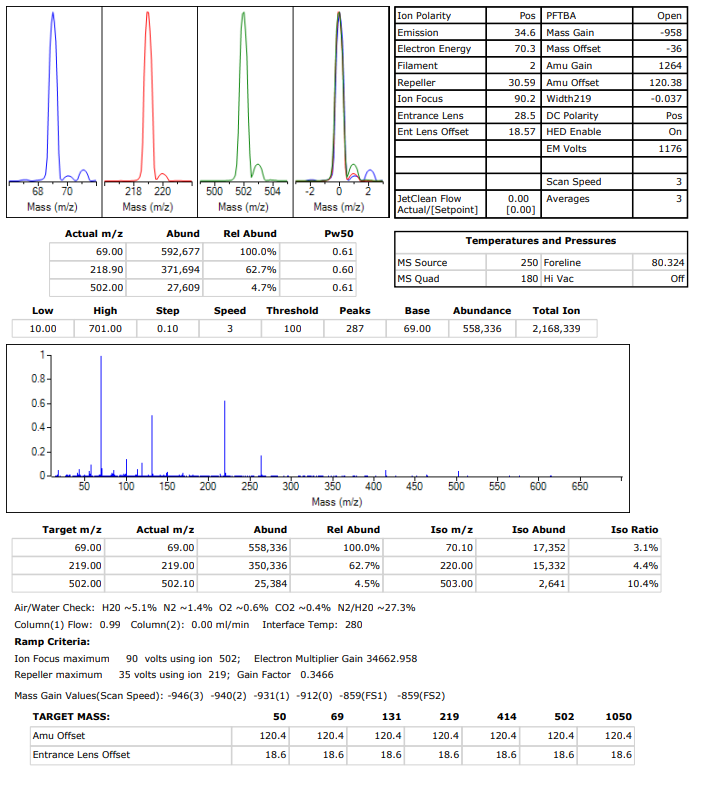

The autotune seems pretty good (with more peaks than usual though as expected from an oil contamination), and is mostly unchanged when changing filaments.

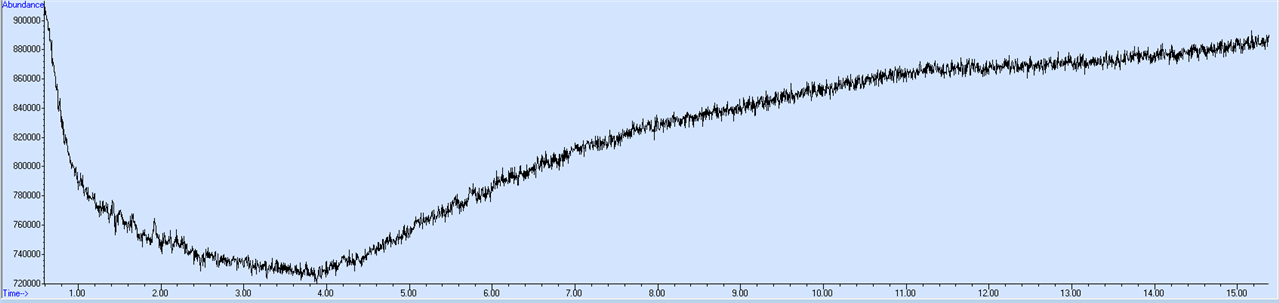

Here you can see an example of a recent chromatogram of what should be a 'blank run' - usually the baseline would be below 10000 counts and have a distinctive baseline jump from 1 min to 5.5 min from the thermal desorption instrument:

The most recent autotune:

Any ideas? Is this just a super dirty MS - and what can be done in that case beyond what I have done?

Or might there be other issues? Can one of the other parts be damaged from the contamination and in need of replacement or cleaning?

I do wonder if there might be multiple issues coming into play here. Before the backflushing of oil, the signal did suddenly start to become super noisy.

Any help is appreciated!