Hello GCMSTQ Friends!

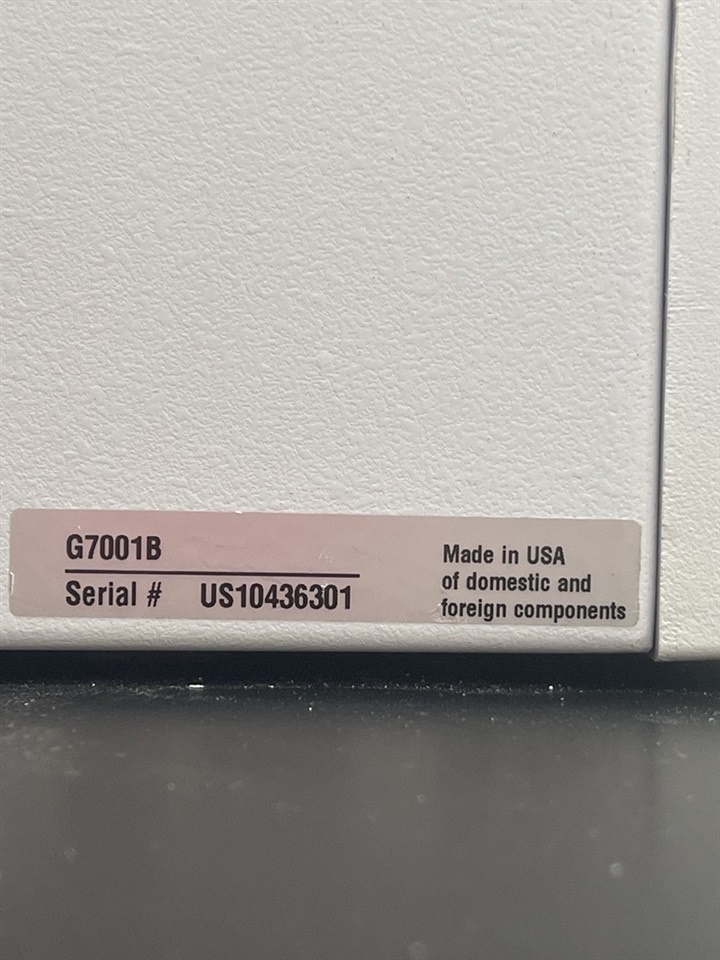

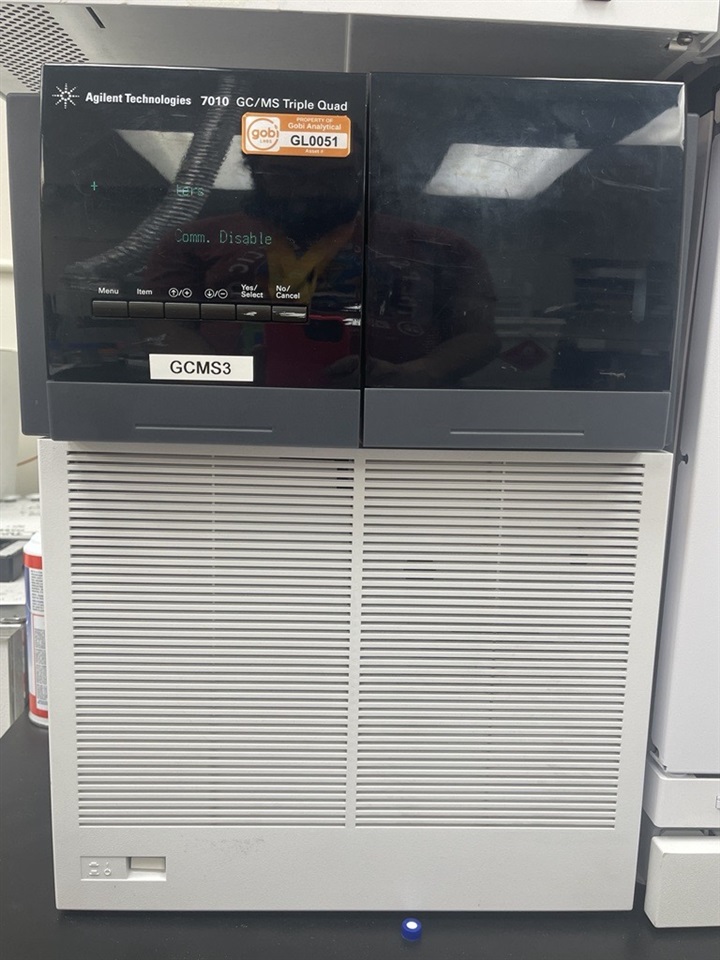

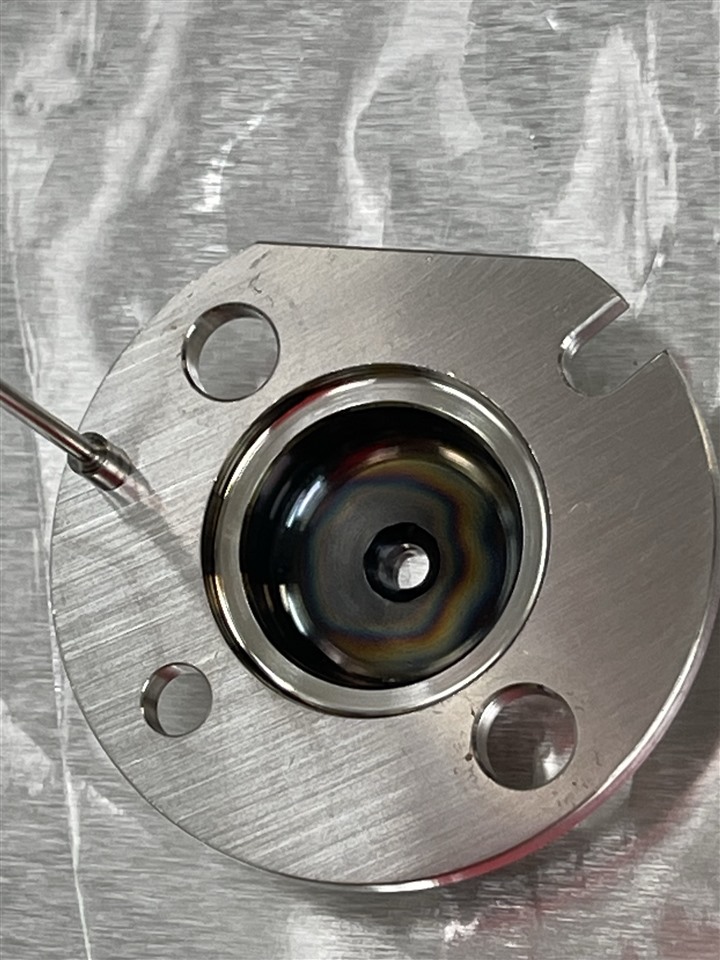

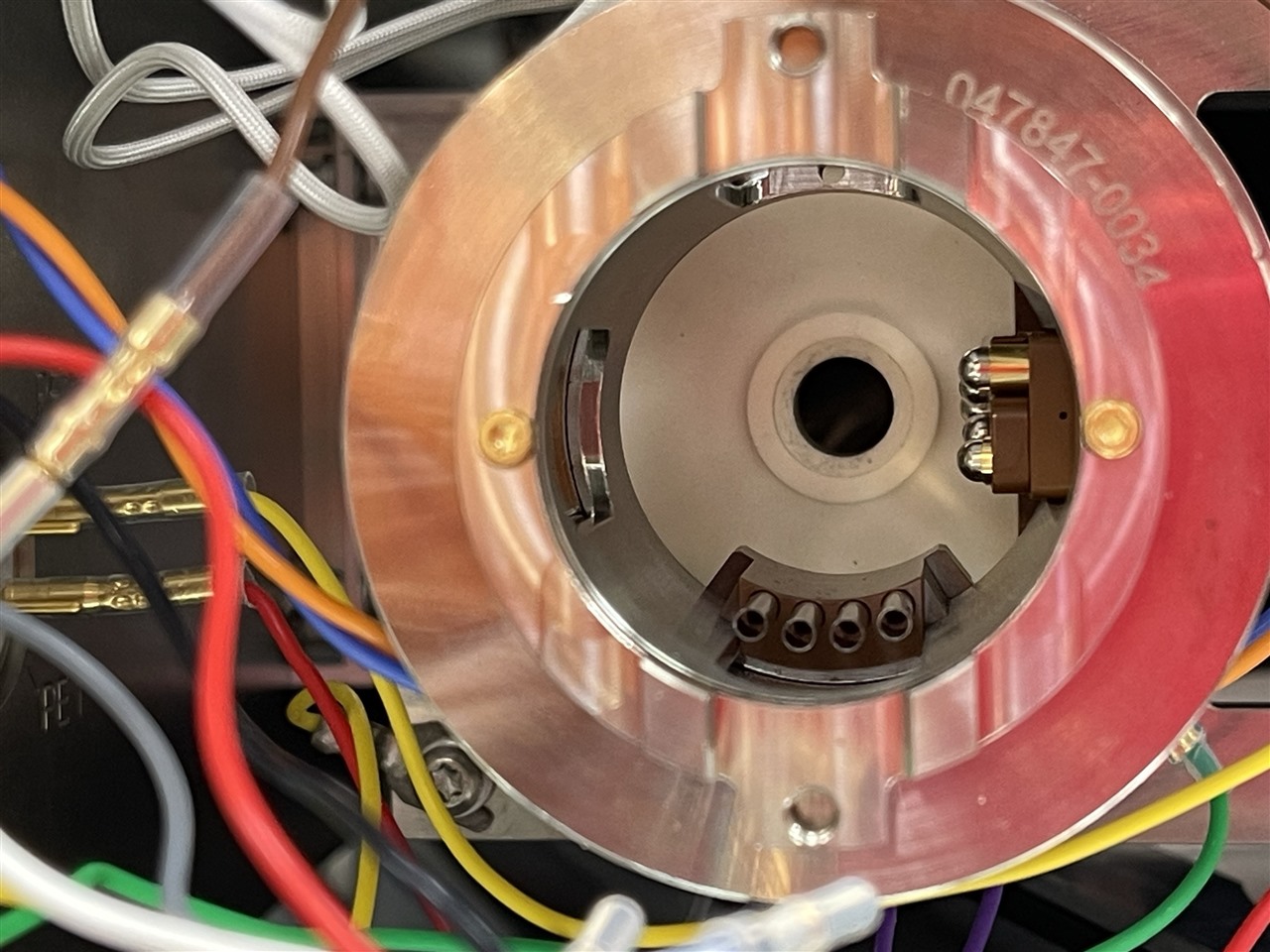

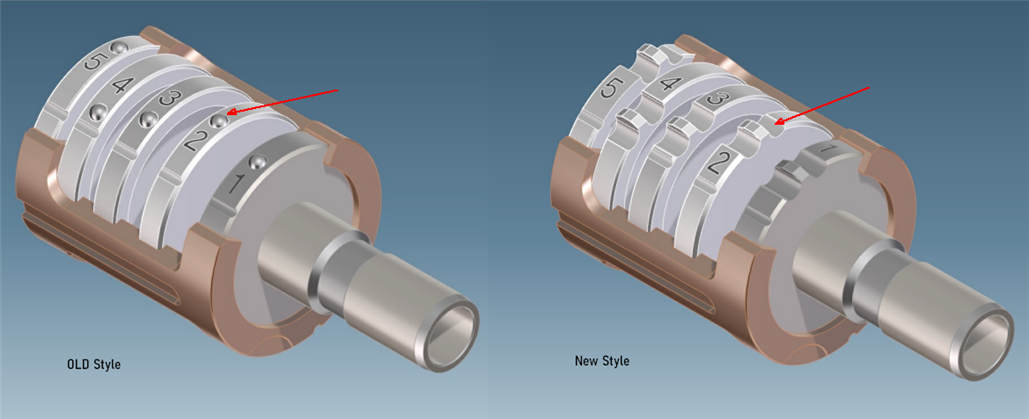

My lab had purchased a 8890/7010 system with HES source (via 3rd party) a few months ago for low level pesticide analysis in cannabis. Previously we have been working with a 7890/7000C with Xtr EI Source for the last few years. Every since we have begun using the 7010 with HES, I have felt there is some issue with MS1 ion abundances, in turn lowering overall sensitivity depending on the tune applied. I am used to 6-10 million counts for PTBFA 69 in my tunes on the 7000C, but was expecting at least double that with the HES.

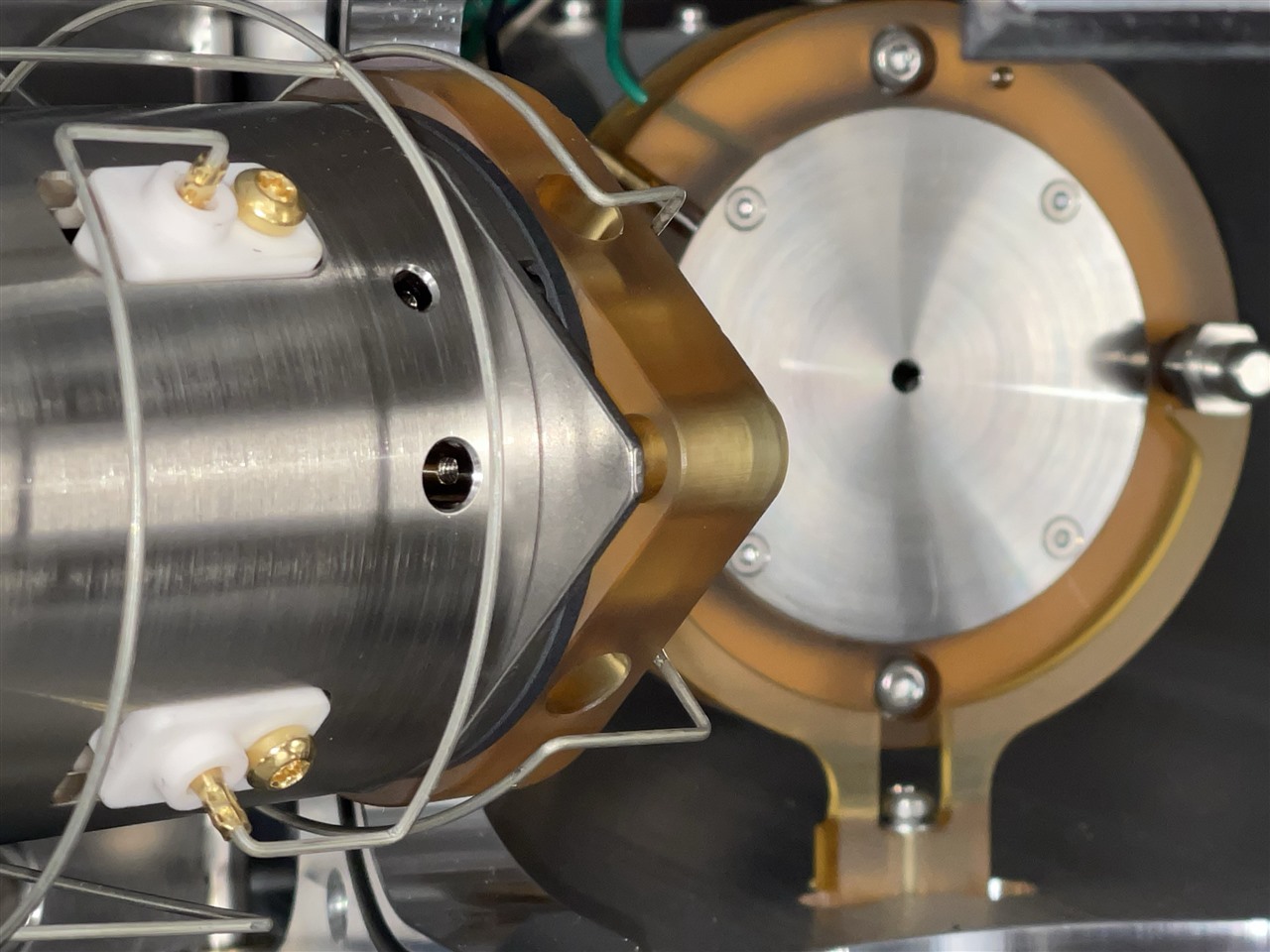

Peak shape of tune ions in MS1 are a bit off shaped, and isotope "foot" resolution is not baseline resolved as it appears to be in MS2 (also relative abundances seem low, particularly in mid and high masses). I have opened profile screening in manual tune to live monitor both MS1 and MS2, and am seeing about 1/3 ion abundances in MS1 as MS2. Is this normal? Should both profile abundances be equal? I have attached 2 versions of tune files, one month apart. I have tried tuning from default a number of times with minimal improvements. In addition, we do have hydrogen jetclean installed on this instrument, so I am pretty sure its not a dirty source.

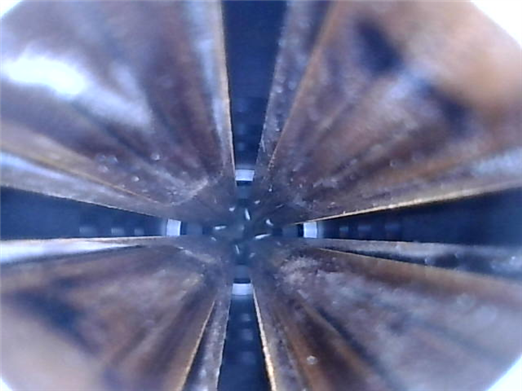

Could MS1 quads be dirty causing this issue?

I would greatly appreciate any and all feedback, Thanks!