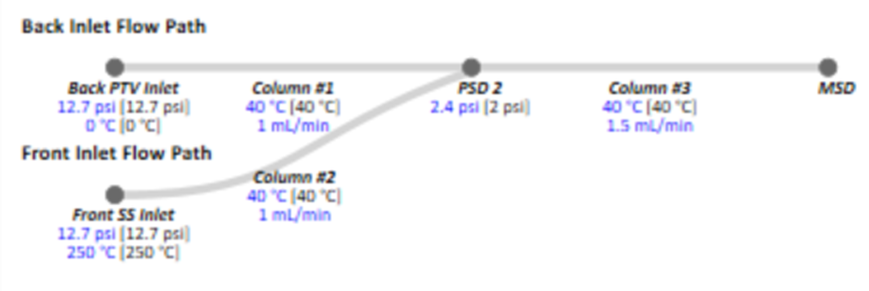

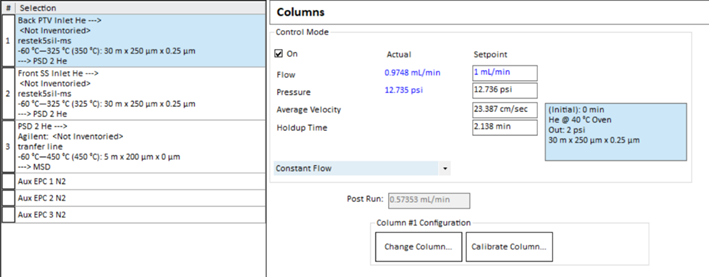

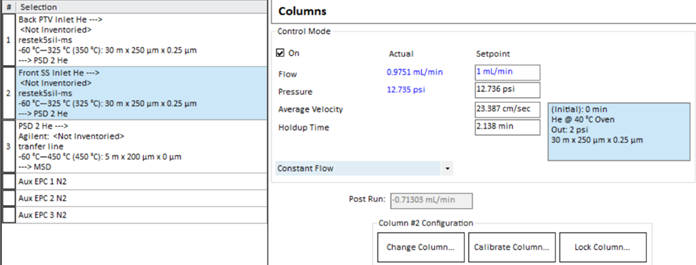

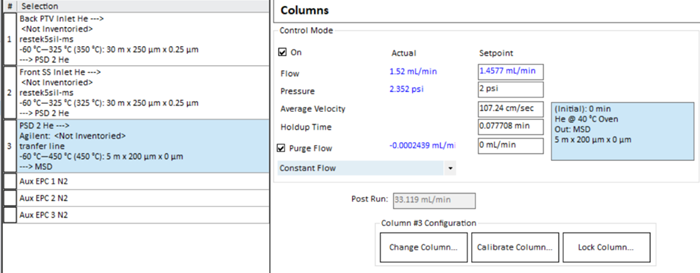

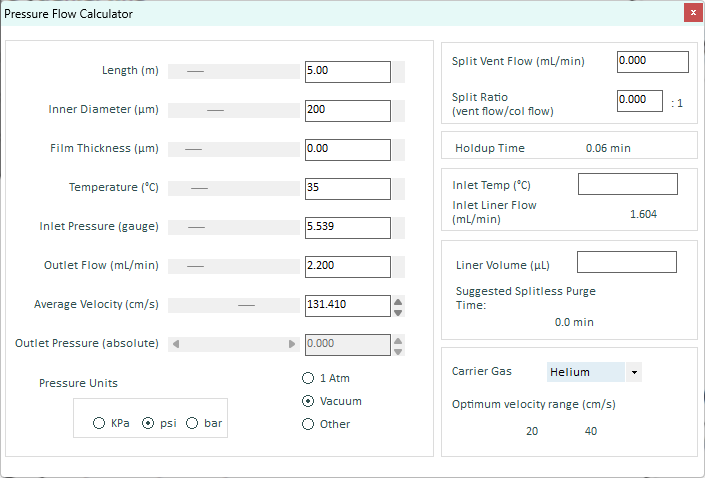

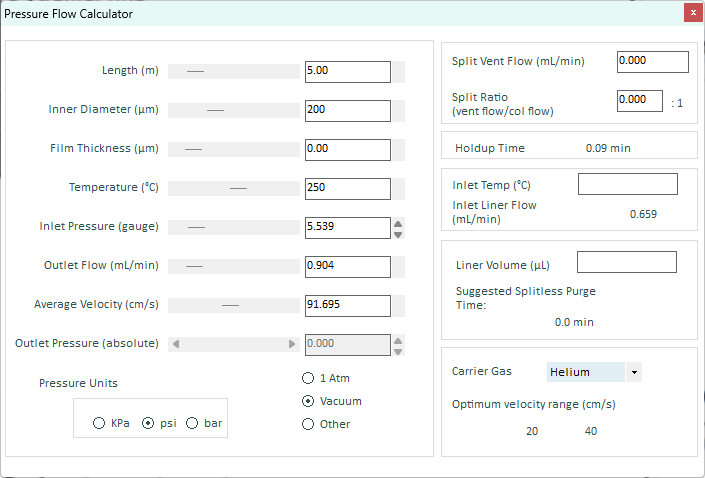

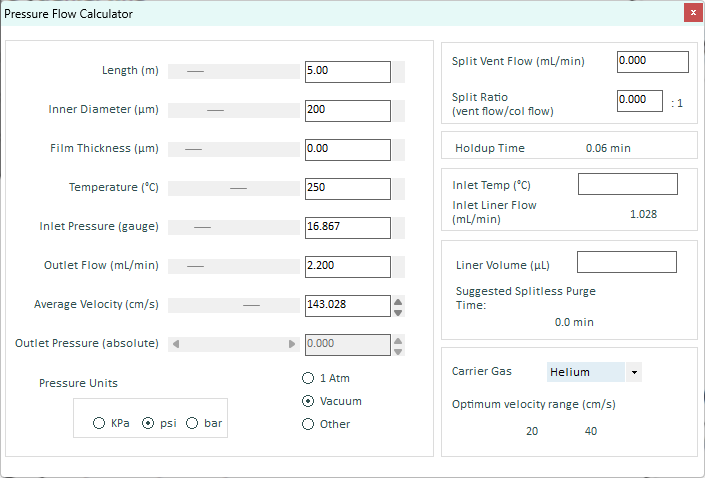

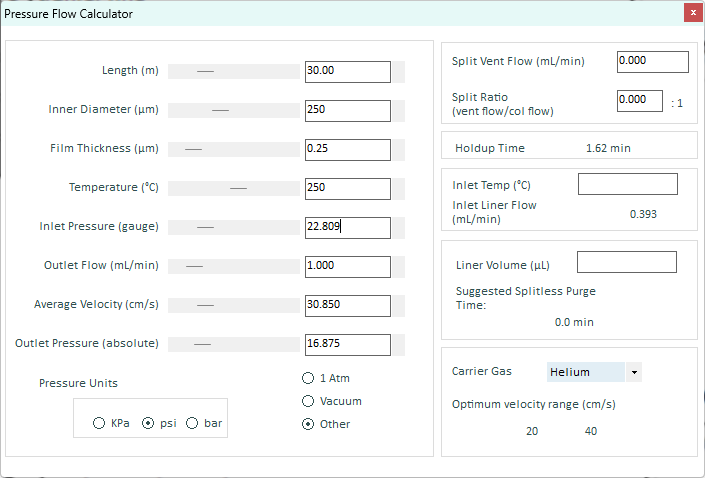

We have installed a second column on the back inlet and need help configuring the flows for both analytical columns and the transfer line. We prefer flow of 1 mL/min for each column, but only the back inlet will be used for now. Should we operate in constant flow or constant pressure? How should we adjust the PSD purge flow?