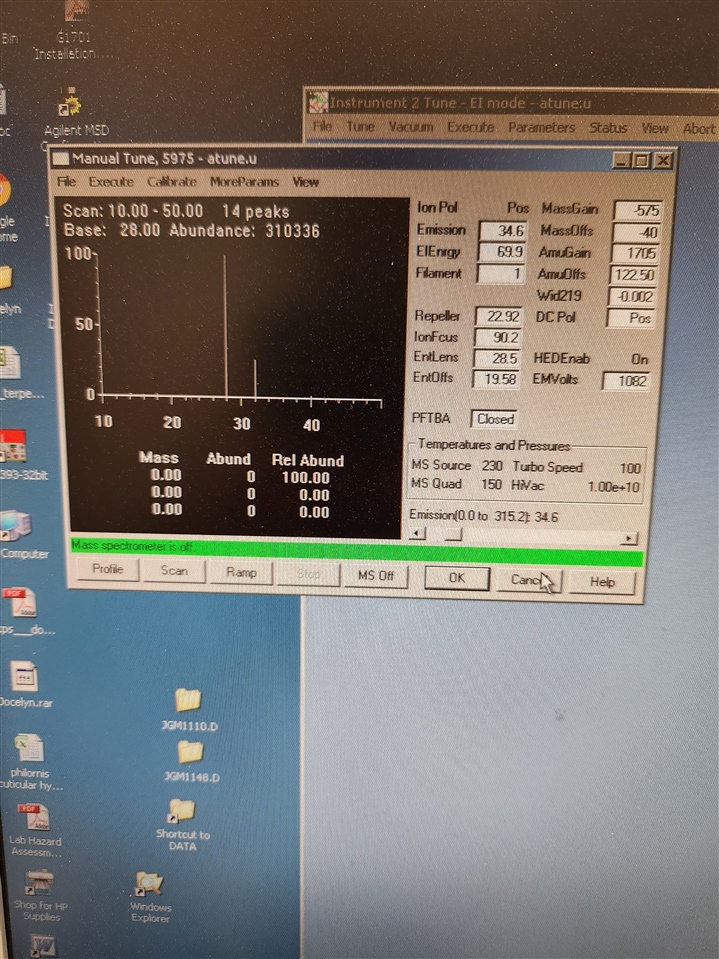

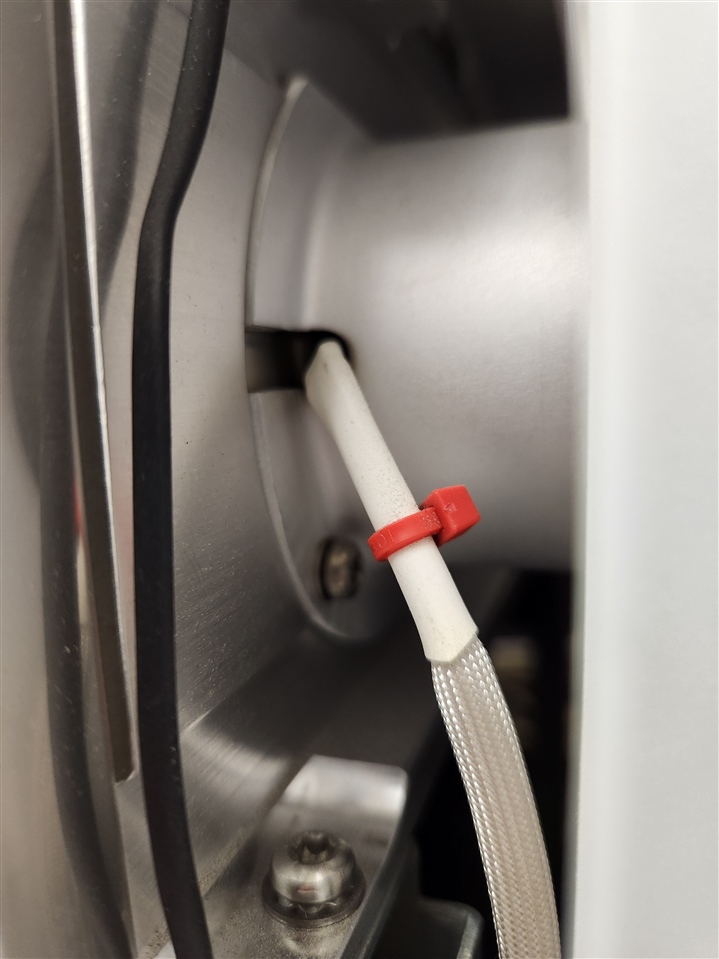

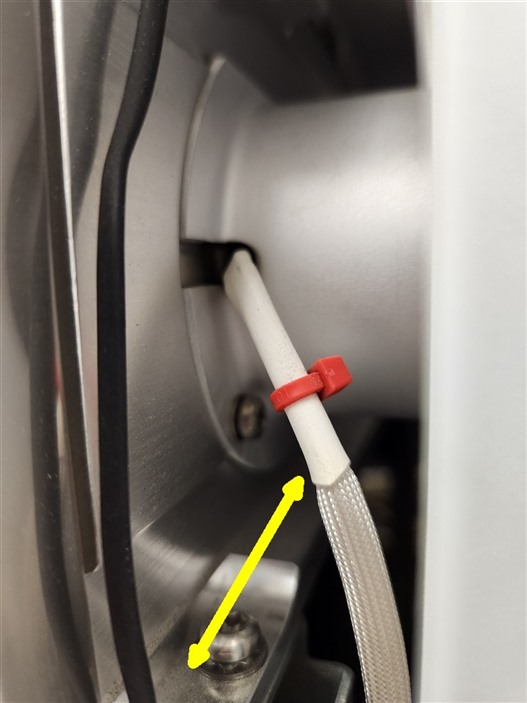

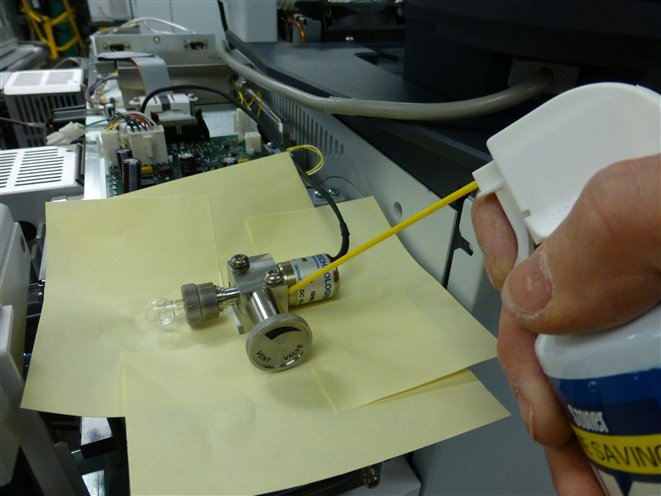

The system we are using is a 6890N GC coupled with a 5975C MSD. After a recent power outage we pumped the system down and discovered a major air leak with Nitrogen being roughly 50% of ion 69 and Oxygen being 13% after waiting 24 hours from the pump down. We scanned from 0-100 with the manual tune and used a flow of Argon gas to test for air leak locations, and found that the usual locations were not showing a leak. We tested: GC/MS interface nut, Vent valve area, MS side plate, foreline pump and hoses, as well as the GC injector and nuts on the GC portion of the system. The only location where we saw Argon in the scan was where a white cord is connected to the MS transfer line (I've attached a picture). No other location around the transfer line or anywhere else in the system is showing a leak. This is a new one for me and I'm unsure what the repair is. Any help would be appreciated.

Sean Halloran

UC Riverside