Hello,

I am having a problem with GC/MS system leaking (Intuvo 9000 with 5977B SQMSD).

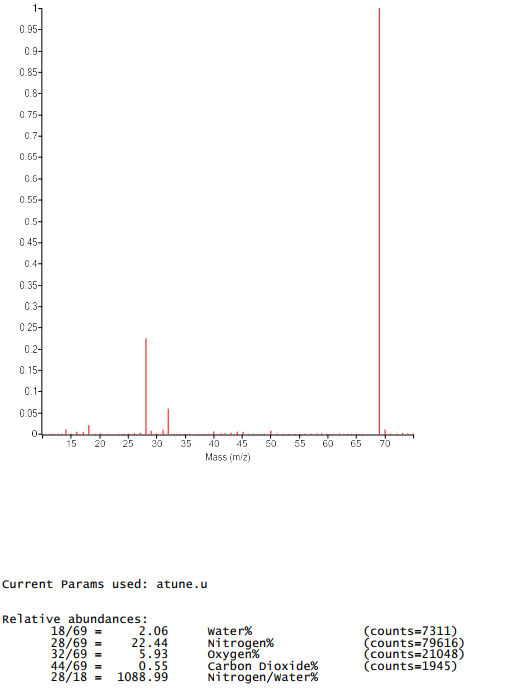

Pretty much out of nowhere, a leak in GC side appeared. MS rules out, as it was enclosed - and leak is non appearing, both in AWL check and simply while profiling air masses. Most usually, with AWL check, there used to be about ~2-3% N2+O2 in system. Now the N2 is jumping ~15-25% and O2 to about 5-7% - nothing was changed prior to it. Leak can't be detected inside GC using air canister, neither with hexane - while profiling appropriate masses for both.

Using the GC "Leak and Restriction" test, system shows unstable (jumping), about 0.1ml flow rate towards restriction.

What has been changed so far:

- Gas Filter (Big Universal Trap);

- Septum;

- Liner and its O-ring;

- Guard Chip (split/splitless);

- All compression bolts (except for guard chip);

- Column and MS Line gaskets (polyimide, 350°C).

Appreciate all the suggestions and ideas, thank you!