Hi, I've been using GC6890N/MSD5975C with no issue but after I recently performed tune evaluation, suddenly the sensitivity decreased severely and there was no peak detected unless very high concentration like 10% loading. Auto tune was fine every time I tested. I do manual injection, so not relevant to ALS, etc.

So, I followed the troubleshooting guide. These are what was done so far;

- replaced septum, liner, o-ring, gold seal, ferrule in inlet.

- replaced ferrule in GC/MS interface

- removed guard columns, cut off ~1 cm of column at each side and re-installed column (same column) with new ferrules.

- cleaned ion-source

- replaced filament

While doing these, there was a leak issue but it got fixed, and auto tune passed.

Surprisingly though, I still have the same problem - poor sensitivity or no peak at all with small loading sample. Tune file was correctly saved and assigned.

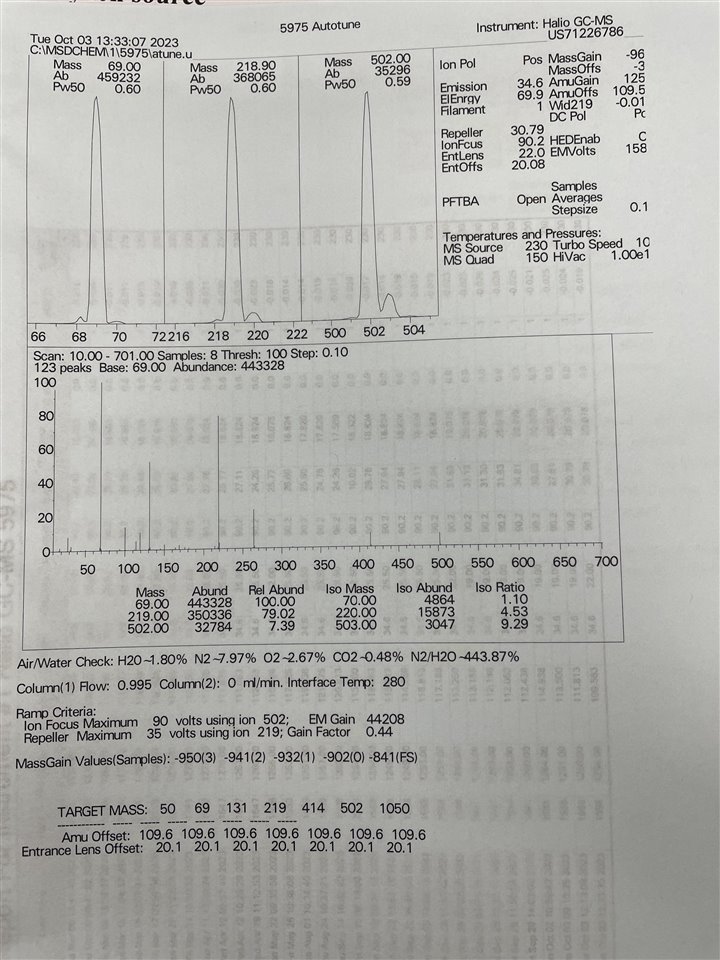

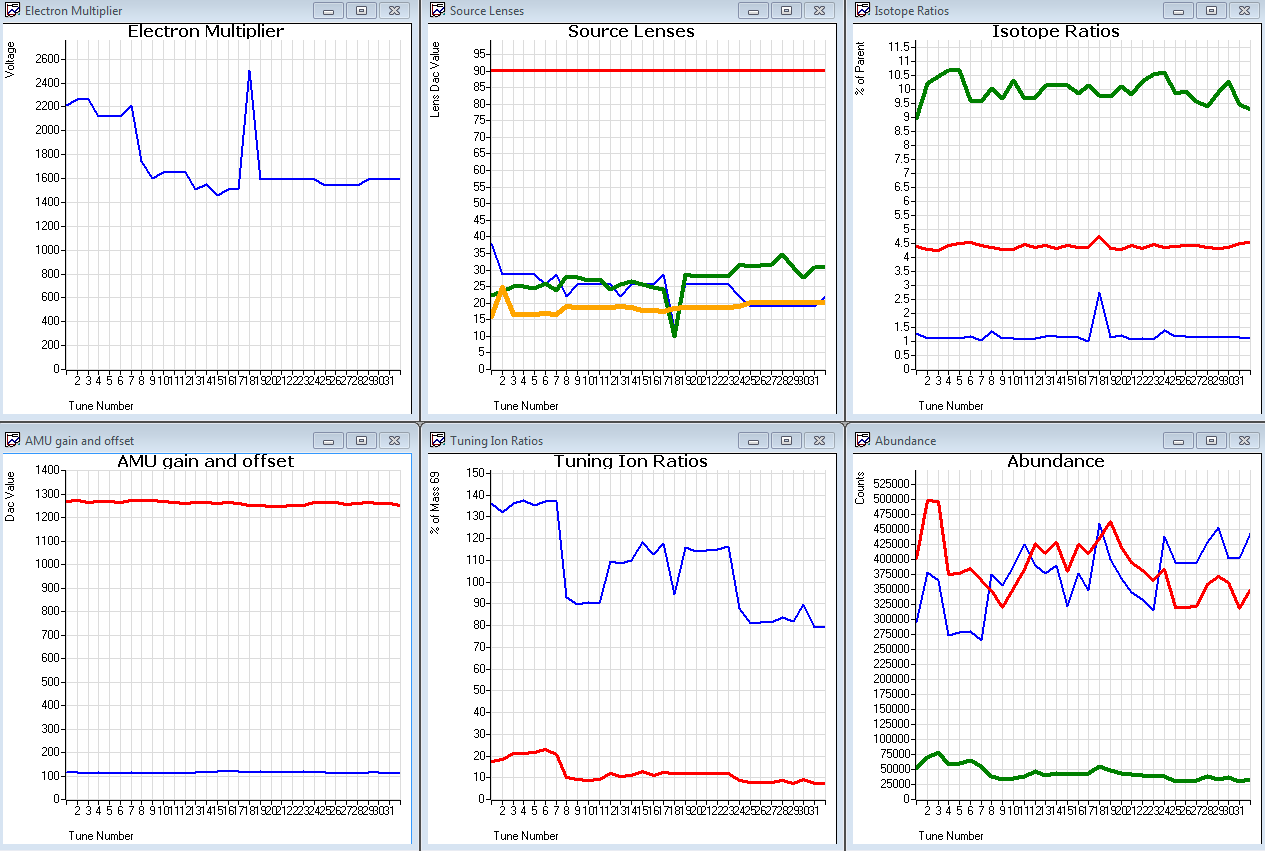

Below is the auto tune report (please note the vacuum reading is not valid because the ion gauge is failing), and the tune views (number 24 is when ion source was cleaned).

Your advice would be very much appreciated. thank you