Hi,

our 5975XL is not performing according to the specifications when using Chemical Ionization. Our tune files look like the ones described in the following question: https://community.agilent.com/technical/gcms/f/gcms-forum/706/autotune-ci Sadly no resolution was found there.

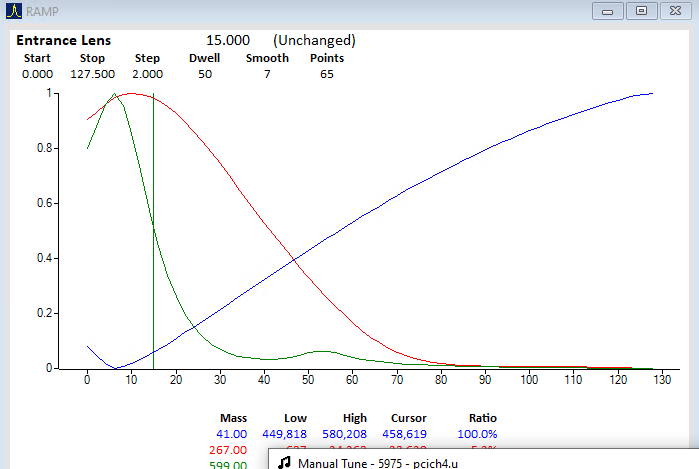

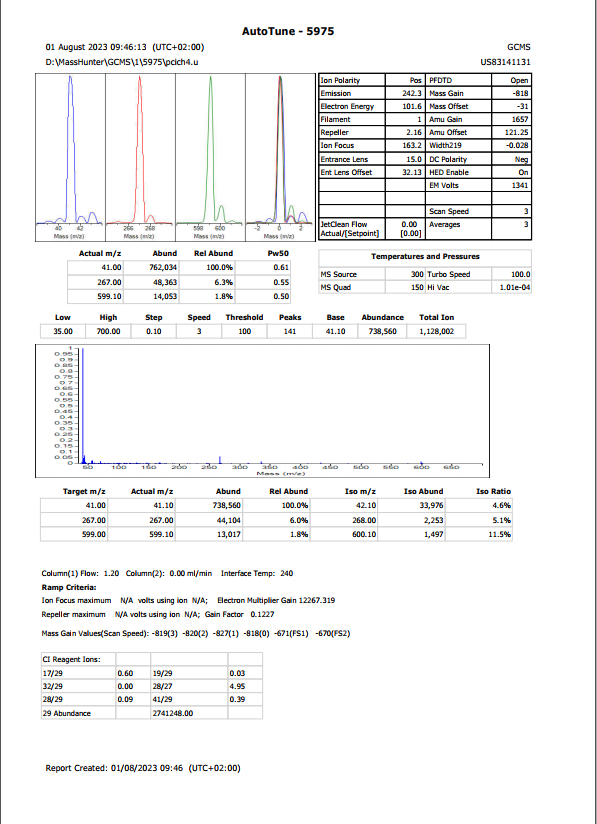

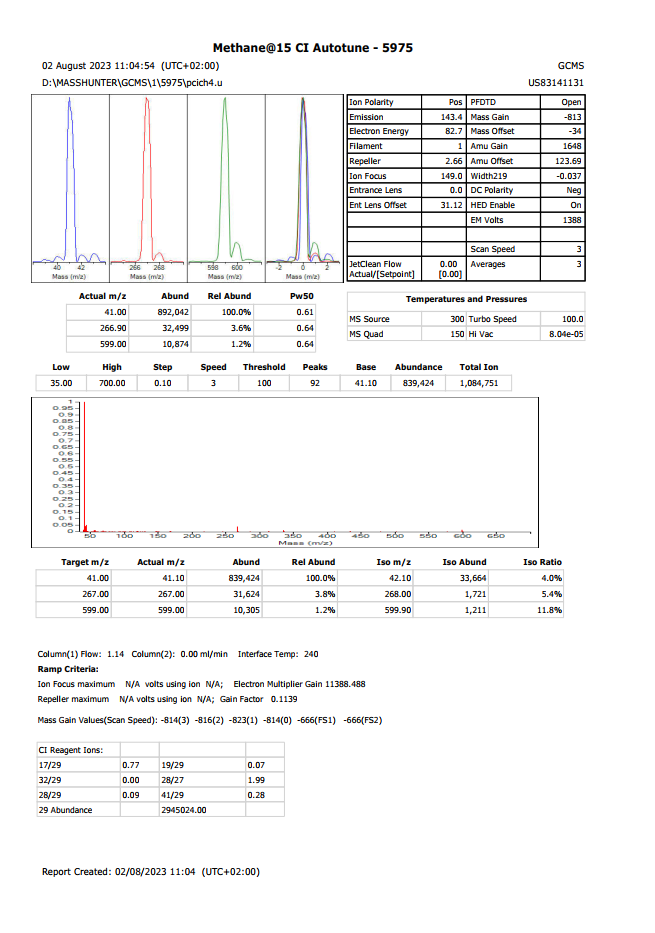

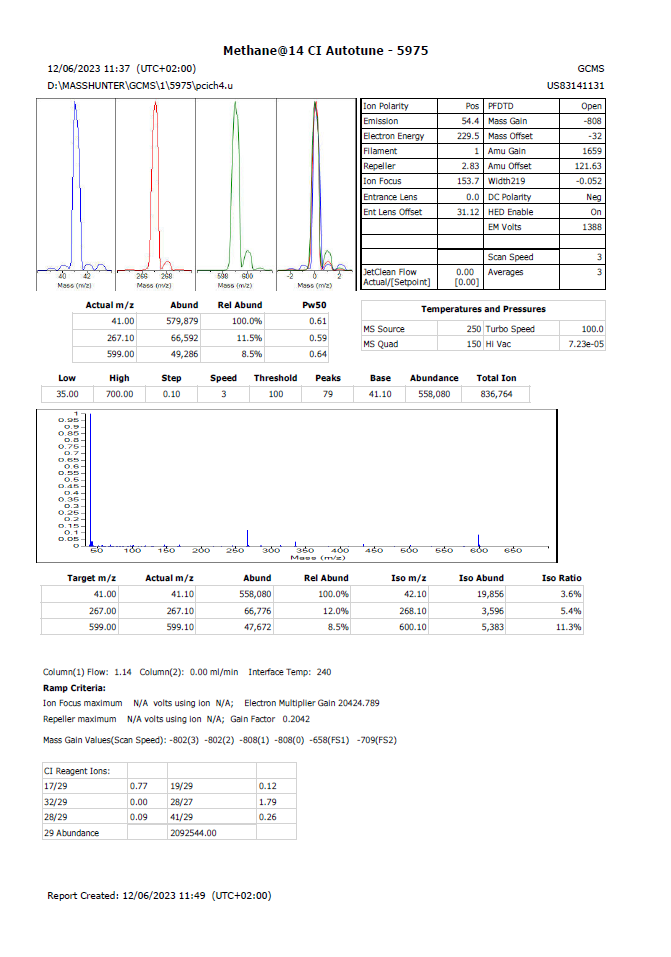

PCI

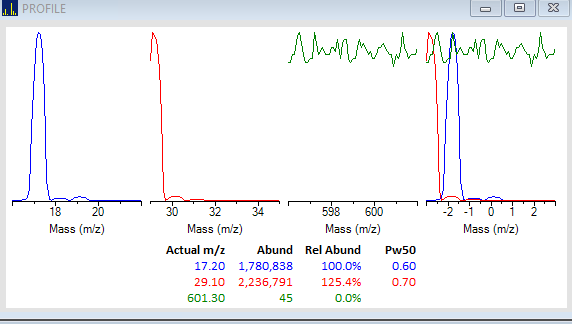

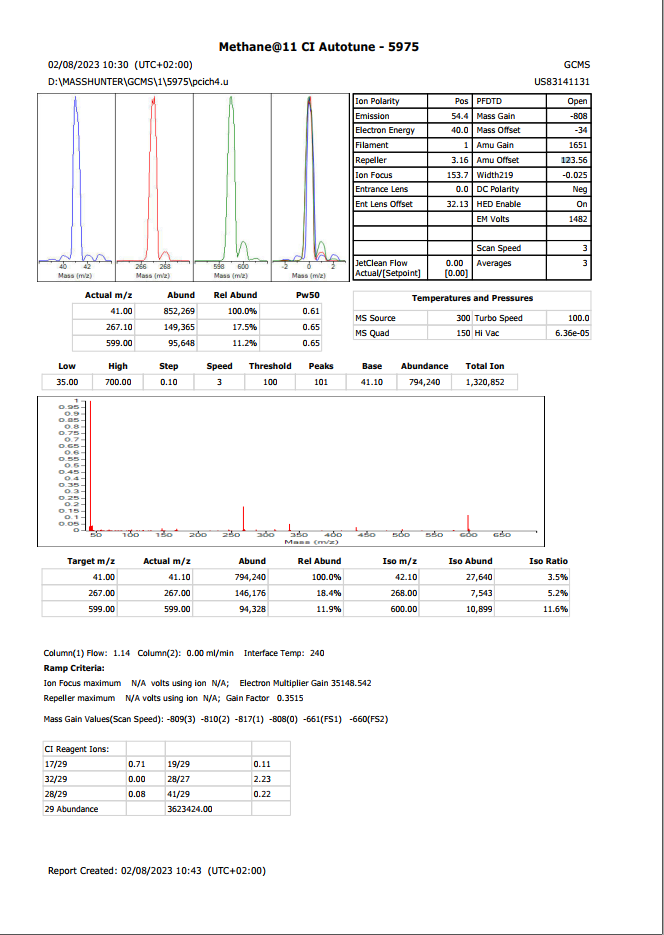

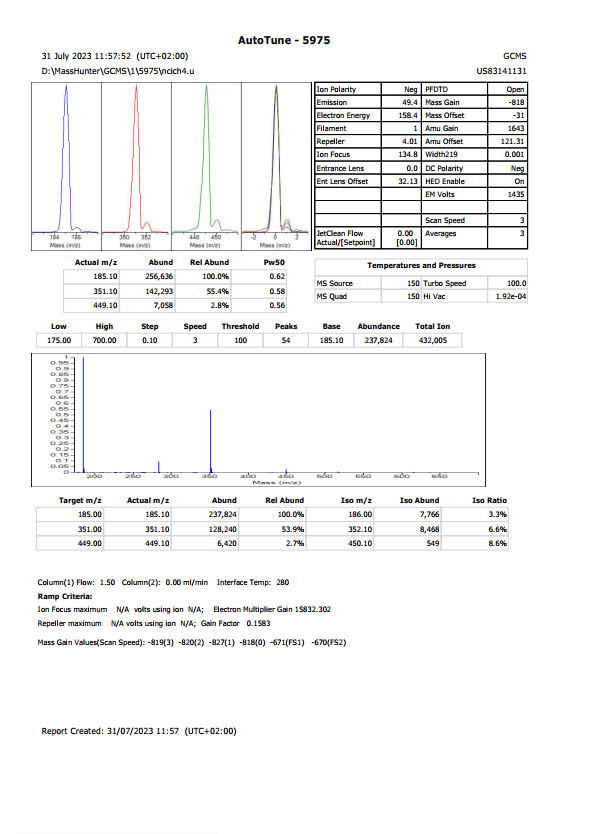

NCI

We tried the following:

1. Swaping the gasline from A to B

2. Changing the gas supplier from Air Liquide to Linde (both methane 5.5)

3. Cleaning of the source

4. Using another source body from an older CI-Source

5. Baking out of source an quadrupole

6. Checking for leaks in EI mode. Nitrogen is about 4 %. Evaluation tune ist successful. EI ist working fine.

7. Changed the CI gasfilter.

An Agilent representative suggested filling up PFDTD. But if PFDTD might be emtpy we would not see any signal at all? For NCI sensitivity ist bad. That is especially the case for m/z above 500 (PBDE und PBB Analysis). PCI checkout as well as NCI checkout do not result in the right S/N. Both are way to low; at least 3 - 5 lower than what we should expect. Unfortunately last year our GC was upgraded with a new sampler an inlet (PTV), so we suspected that some problems may arise from this but all our measurements in EI-mode perform perfectly.

We hope that somebody has an idea on how to resolve this issue, because we need the MSD for brominated an fluorinated substances.

Thanks for any input concering this issue.