I ran an autotune and the tune evaluation. It says 502 precursor is too high and contact Agilent service engineer. Any thoughts on what could cause this?

I ran an autotune and the tune evaluation. It says 502 precursor is too high and contact Agilent service engineer. Any thoughts on what could cause this?

The tune report says your column flow is 6.607 ml/min, which dramatically exceeds the maximum allowable flow into the GCMS. Yours has a diffusion high vacuum pump and the absolute maximum is 2.0 ml/min or else damage could occur from backstreamed diffusion pump fluid. Turn the flow down into the recommended 0.8 to 1.4 ml/min range, 1.2 ml/min is used on most systems, then tune again and post those results please.

Tune ion peak precursors, splitting, and tilting/asymmetry are related to the quadrupole itself, but poor vacuum could certainly cause this.

I should have mentioned that this is a GC-MS/FID.

What is the flow into the MS? What is the configuration of the inlet, column(s), splitter, restrictors, etc?

How many injections have been done on this 24 year old system?

The most probably cause of tune ion peak precursors/splitting/tilting/asymmetry is that the quadrupole has sample residue deposited on it that is affecting the electrostatic Rf/DC fields that filter the ions. The system needs remedial cleaning including the quad, quad radiator, source, source radiator, side plate, and the entire inside of the vacuum chamber to reduce the amount of sample residue that is continuously redistributing inside. A quad cleaning may resolve the precursor but without cleaning everything it will happen again sooner.

So this instrument runs air samples. It has probably done thousands. and thousands of injections.

How long is the piece of 0.25mm id capillary column going into the MS and what is the pressure at the end of the 0.53mm column? Or, what is the inlet pressure and the lengths of every segment with a diagram so that I can try to figure it out.

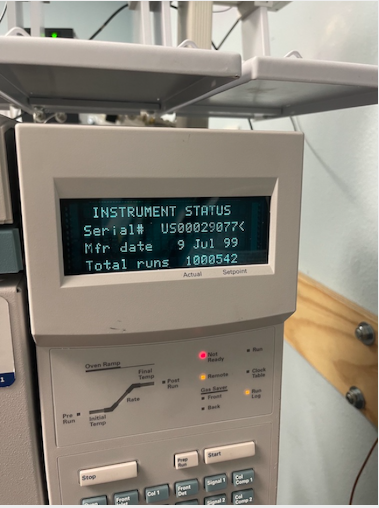

Every time I walk up to any Agilent GC, I show the operator how to see the number of injections.

8890 and Intuvo: Service Mode, Instrument, Usage

7890: Service Mode, Diagnostics, Instrument Status

6890: Options, Diagnostics, Instrument Status

It might be worth venting and either put a 30x250x.25 column from inlet to MS, configure it properly, set it to 1.2 ml/min, let it pump for a few hours, and then try it again. Or, vent and cap off the MS transferline. That is not necessarily a completely valid test, but will help see if too much flow is the issue or a contributing issue.

Inlet pressure is set at 12.0 PSI. The total number of injections 1000542.

Inlet pressure is set at 12.0 PSI. The total number of injections 1000542.

The GC counter rolls over at 999,999...but 100,542 is still a lot!

Great drawing, thanks. That setup makes it difficult to figure out pressures/flows. The path of least resistance is all of the 530 pieces unless the methanizer and the connection from that to the FID is restrictive. 30.14meters of 530uM with 12psi to an FID would be 15.769 ml/min at the FID. The pressure at the tee to the MSD is just barely less than 12psi, and the GC Pressure/Flow Calculator says at 100°C that 11.985 psi would result in 1.119 ml/min into the MS.

Even if we discount all the rest, 12.0 psi, or a tick less, at the head of a 30x.25 column into the MS would result in a flow that is in the typical range.

So the remedial cleaning would be what I would recommend.

So I've heard that cleaning the quads can be tricky, I've only ever really cleaned the source. Is there a detailed manual on how do this remedial cleaning?

well, wow! I remember setting one to 999,999, pressing start and it rolling to 000,000....but it must have been that I set it to 9,999,999 or 99,999,999 and it rolled over. That was probably 15 years or so ago. Amazing. A new high score winner. I thought the one I touched this week with 202,000 was a lot!

Agilent does not recommend that operators perform quad cleaning as the chances of causing damage is quite high without training. I would suggest you contact your country's Agilent field service and schedule a visit.

Will do! Thanks for the help!