We were having many issues the last months with our GC-7200 qtof system. Many have been resolved, but we are left with tailing on later eluting peaks (phthalates, starting at about 250 °C) and oscillations coming from the splitter plate.

Our system is as follows:

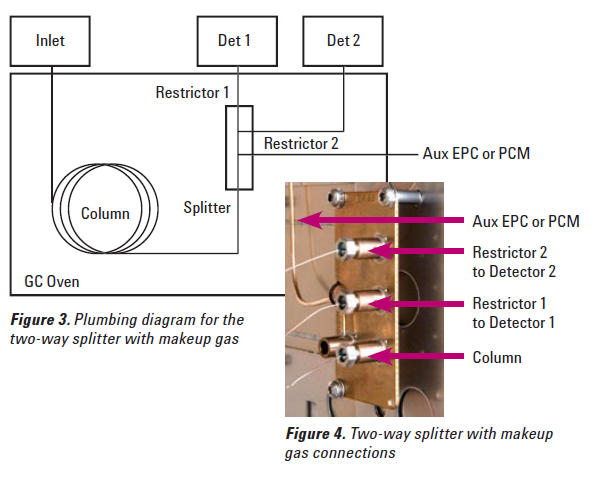

KAS-inlet (Gerstel), 15m column - backflush - 15m column - splitter plate - FID/qtof

The tailing is only on the MS side, and not on the FID. Oscillations are on both channels (and on the actual pressure reading of the corresponding EPC).

We extensively checked for leaks (with a duster), so splitter plate is good. I checked the inertness of the inlet side (including backflush) with the GC degradation mix from Restek (I know that it shows me leaks up to the backflush), so inlet/backflush is fine too.

Also, analytical columns are in few months only and the system has hardly seen any samples. Transfer line has been exchanged again last week and tailing stayed. (Again, resolution is perfect on the FID!) MS source has been cleaned several times and hardly any samples have been on it since.

Any ideas what the oscillations on the splitter plate are coming from and how to resolve it?

Any ideas on the tailing of later eluting compounds? (Could it possibly be the transfer line that's not heating evenly? How to check for this?)