Hello Community,

I have been noticing random peaks, made from 1-2 data point(s), appearing in my samples where nothing should come out.

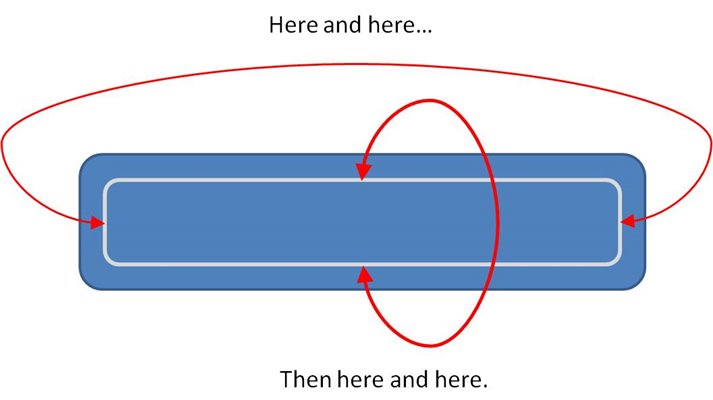

In the image below, the first chromatogram is the way it's supposed to be while the others show the mentioned peaks.

What could they be? Dirty injector, dirty detector, failing column...?

Highest m/z: 281, 282, 283

Thank you.

Happy Easter!