Hi

I am pretty new to GCMS, so may need extra details on how to do things you suggest

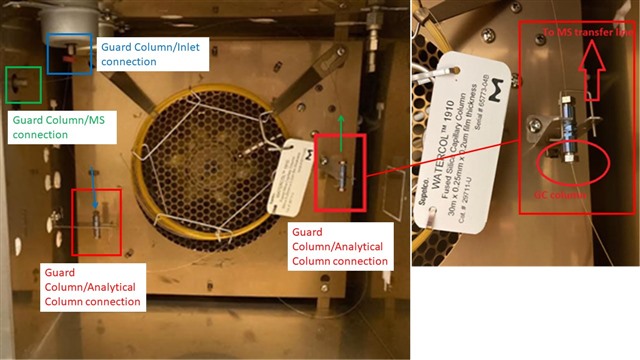

I attached a picture of the set up of our gc system, so I can explain better. We recently installed a guard column using 30 cm piece of FS Deactivated 0.250 mm(Agilent PN 160-2255-30) . We reused the column nut shown in a separate picture because we did not have a new one. We installed it without a ferrule (which I am not sure if a ferrule is needed or not as it seems to have a ferrule inside (or at least it looks like it. I measured 5 mm of the column end sticking out and inserted and tightened it into the inlet. We had issues with a leak afterwards with N2 values varying from 22 to 16% and O2 values varying from 7 to 5%. I tightened fittings, replaced inlet and septum. Nothing helped. Mass spec does not seem to be an issue.

When I read the installation instructions and it seems a ferrule is needed. I removed the column again and reinstalled it with a Graphite Vespel Ferrule P/N 290VA191 from Thermofisher (did not have any ferrules of that type/size from agilent. But

For the analytical column (which is Restek RTX-5MS, 0.25 mmID, 0.25 um df (PN :12623) I use these Agilent ferrules G3188-27501 (for 0.1-0.25 mm). Unfortunately I ran out of these while failing to do proper trimming after tightening the ferrule and used G3188-27505 (for 0.35-0.32 mm) for one of the analytical column connections. I'm seeing the same issues. Now the values are even higher N2 250%, O2 80%.

I tried to follow this video for leak check https://www.youtube.com/watch?v=hwPNejGBuqk , but there is no option for septum purge flow. When I set the purge flow to 50 and the column flow to 7, the total flow is 59.5. I don't understand why the total flow should be less than 10. Isn't the total flow all flows added up? Then in my case it should be 57.

Feedback, guidance, suggestions would be great.