Hello,

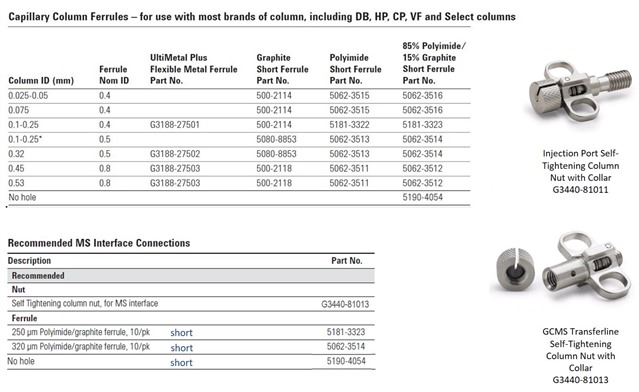

I confirmed I have a leak at the MS interface of a 7010 GC/MS TQ. Roughly 22% H2O and 22% Nitrogen and 6% oxygen. I tried two different self tightening nuts and also the older model MS interface nut while using a no hole ferrule and still can observe the leak. Is it possible MS interface itself is damaged and is this part replaceable? Are there no-hole ferrule that would fit the newer self tightening nuts, if so what is the part number?