How to Identity the Root Cause of Common GC/MS Issues

Where can problems in your GC/MS System occur? How can you identify what part of the GC/MS system you should be troubleshooting: gas supply, GC inlet, column, transferline, ion source, quadrupole, detector, tune file? Or should you be looking somewhere else?

======================

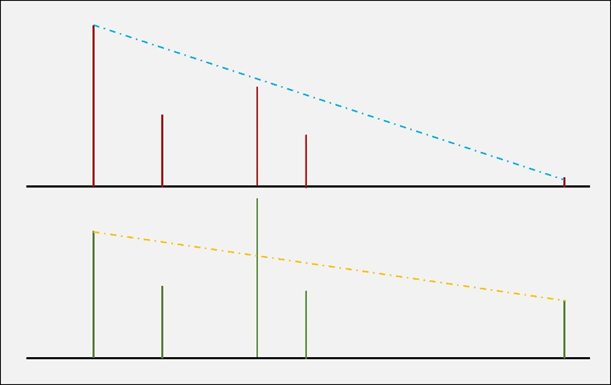

Image 1: Spectral Tilt Differences, Grossly Overexaggerated

Ion ratio problems are identified by unusual tune ion ratios or low library search match quality. This is also called spectral tilt. It is most often the result of a dirty ion source, misassembled ion source, or old/dead filaments.

The GC inlet cannot cause ion ratio problems. This is true unless:

- there’s a leak that causes a dirty source

- the injection volume is too large causing overloading/saturation which dirties the source

- the concentration is too high causing overloading/saturation which dirties the source

- the column flow is too low or too high which affects the ionization chamber vacuum

The Column cannot cause ion ratio problems. This is true unless:

- there’s a leak now that is damaging the column so there’s column bleed dirtying the source

- there was a leak that already damaged the column and column bleed is dirtying the source

- the column flow is too low or too high which affects the ionization chamber vacuum

- the wrong gas is plumbed, and the gas configuration is wrong

The transferline cannot cause ion ratio problems. This is true unless:

- there’s a leak

- the column is sticking out too far into the source

- the setpoint is lower than the boiling point in vacuum of the peak of interest

- the setpoint is higher than the column max and column bleed is dirtying the source

For more information, see:

- How to Clean the EI/CI Source in the Agilent 5977A/B

- How to Clean an Agilent GC/MS Ion Source

- GC/MS Ion Source Cleaning Videos

======================

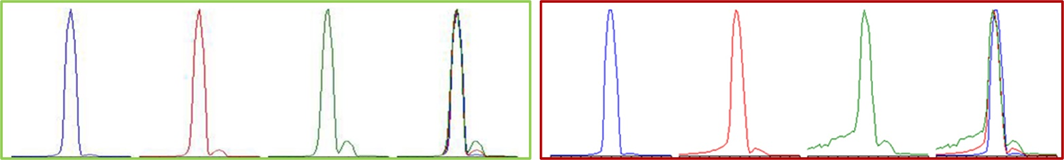

Image 2: Comparison of Tune Peak Shape

Good Ion Tune Peak Shape Poor Ion Tune Peak Shape

The inlet, column, or transferline cannot cause tune ion peak shape problems unless the flow is so high that the vacuum is bad which affects the ion source and quadrupole operation.

The source cannot cause tune ion peak shape problems. It only makes the ions and focuses them into the quadrupole. They are not tune ion peaks until they have been filtered by the quadrupole. The ions coming out of the source are always exact mass – 68.9947, 130.9915, 218.9851, 263.9866, 413.9770, 501.9706, 613.9642. That is chemistry and physics. On SQ and TQ system, the tune ion peaks have width because of the way a quadrupole mass filter functions. Any mass assignment or tune ion peak width problem can come ONLY from the quad(s), quad driver circuitry, DC polarity, poor vacuum, bad tune file, etc., and cannot be from the source.

The detector, the High Energy Dynode or Electron Multiplier, cannot cause tune ion peak shape problems, they are just multiplying.

For more information, see:

- Reviewing the Autotune Report for Agilent 5977 GC/MSD Systems in EI Mode

- How to Reset the Agilent GC/MSD Tune File to Default Values

======================

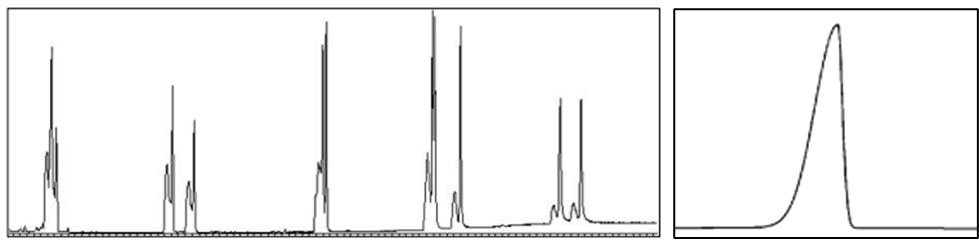

Image 3: Chromatographic Peak Shape

The MS Ion Source cannot cause chromatographic peak shape problems like splitting or fronting. This is true unless:

- there is overloading or saturation

- the peaks are very small, less than 3x to 4x the background noise

- the source temperature is lower than the boiling point in vacuum of the peak of interest

- some weird things may happen with hydrogen carrier gas and some chemicals

The quadrupole cannot cause chromatographic peak shape problems -- except for overloading/saturation.

The HED/TAD/EM cannot cause chromatographic peak shape problems -- except for overloading/saturation

Poor chromatographic peak shape is sample, sample handling, syringe, inlet choice, inlet mode, inlet flows, inlet temperature, initial oven temperature, oven profile, or rarely column related.

For more information, see:

======================

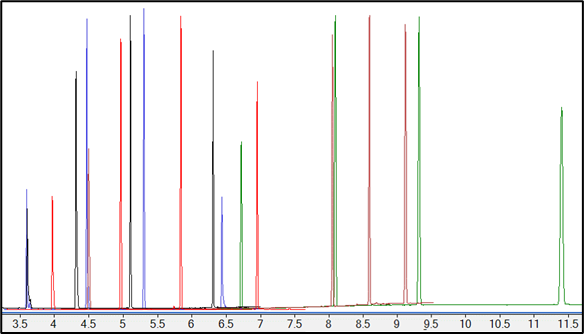

Chromatographic Peak Retention Time

Image 4: Chromatographic Peak Retention Time

The GC/MS source, quadrupole, and HED/EM cannot cause chromatographic peak retention time problems like retention times shifting faster or slower or retention time wander. They are caused by gas supply, leaks, inlet pressures, inlet flows, varying temperatures, and other instabilities.

For more information, see:

======================

Consider what could be causing the problem before replacing parts, changing parameters, or assigning blame. Know what should be normal and be able to identify the symptoms and part of the system that might cause those symptoms to occur.

DE48612755

.

.

.

-

ISH

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Comment-

ISH

-

Cancel

-

Vote Up

0

Vote Down

-

-

Sign in to reply

-

More

-

Cancel

Children