Hello

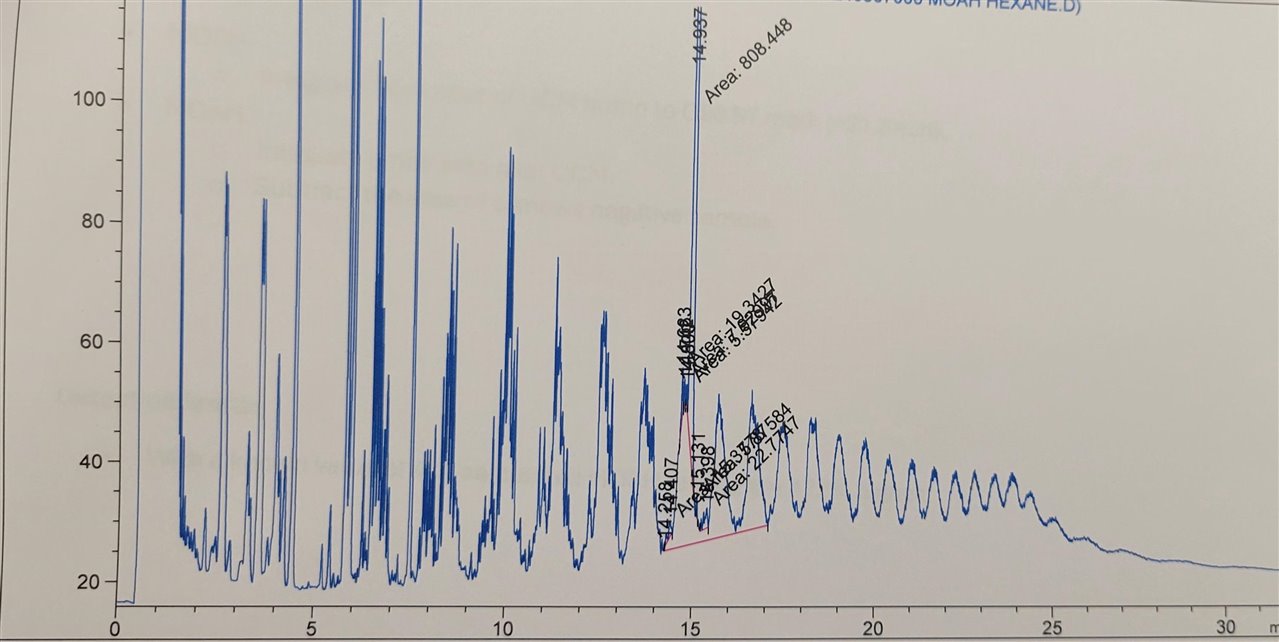

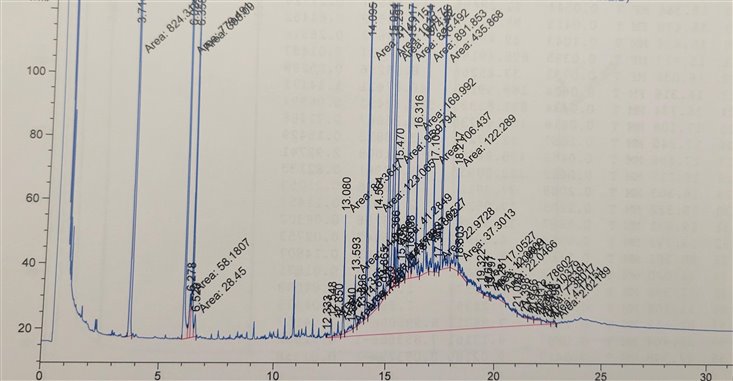

We are working on developing a method for detecting mineral oil contamination (MOSH and MOAH) in edible oils. We are able to get MOSH (mineral oil saturated hydrocarbons) to work well, but when we inject a sample for MOAH (mineral oil aromatic hydrocarbons we are getting a wave in our baseline during the ramp. I believe it bay have to do with the sample itself, because I don't see this on the blank injection or the MOSH injection using the same GC parameters. Has anyone seen this before or have any suggestions.

The samples are in iso-octane. But the MOAH sample may contain traces of other solvents such as DCM and toluene.

The GC is a 7890A with a PTV inlet configured to inject as if it was on-column using a Restek liner, Catalog No. 24977. Detector is a standard FID.

We are using a 15 m, 0.32 mm, 0.10 µm DB1-HT column with a 5m, 0.53mm retention gap/ guard column.

GC parameters are as follows:

Oven

Equilibration Time 1 min

Max Temperature 400 °C

(Initial) 40 °C

Hold Time 2 min

Program

#1 Rate 5 °C/min

#1 Value 50 °C

#1 Hold Time 0 min

#2 Rate 15 °C/min

#2 Value 350 °C

#2 Hold Time 8 min

PTV Inlet H2

Mode: Splitless

Pressure: On: 9 psi

Total Flow: On: 16.686 mL/min

Septum Purge Flow: On: 3 mL/min

Gas Saver: Off

Purge Flow to Split Vent: 2 mL/min at 1.5 min

Temperature

(Initial) 40 °C

Hold Time 2 min

#1 Rate 5 °C/min

#1 Value 50 °C

#1 Hold Time 0 min

#2 Rate 15 °C/min

#2 Value 350 °C

#2 Hold Time 8 min

Detector FID

Makeup: N2

Heater: On: 370 °C

H2 Flow: On: 40 mL/min

Air Flow: On: 400 mL/min

Makeup Flow (Combined): On: 25 mL/min

Carrier Gas Flow Correction Included in Makeup Flow

Flame: On