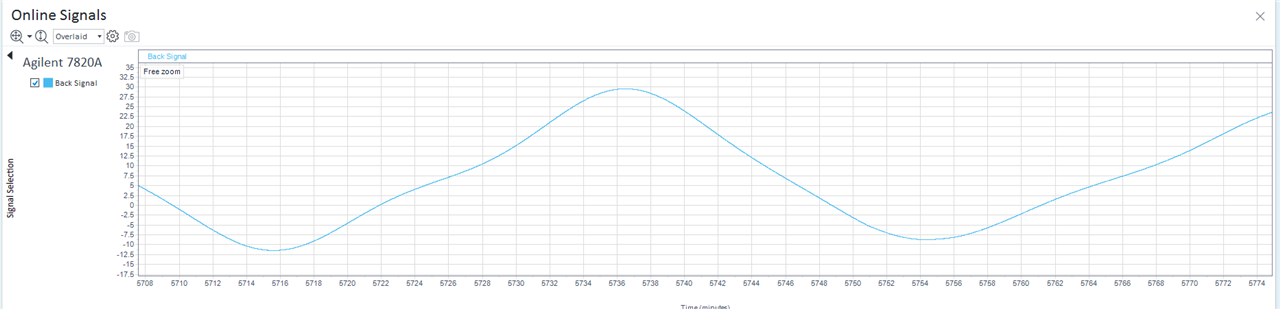

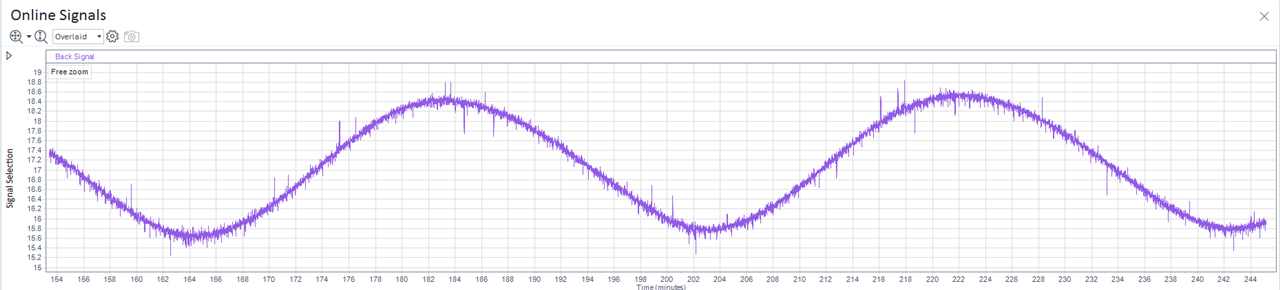

I am experiencing sine wave behavior on the TCD signal for 4 different GC systems (all 7820A). I've attached two images for reference. All systems use He for column and reference/makeup flow. All systems operate under the same testing method, and so have the same detector temperature. These images show the signal "at rest" as in with no sample running, with full column flow and full reference/makeup flow. The "waves" do not appear synced across the systems.

My working theory is that we have a leak in our He lines. This could explain the behavior and why all the systems are affected. We have a primary gas manifold with 3 tanks hooked up which supply the He for all 4 systems. However, I checked the manifold thoroughly and could not find any leaks. There were also not any leaks I could find in any of the 3 tanks. The common thread for all the systems is the He source, so this is what I have been focusing on.

I am posting the following question: Is there another factor I could have overlooked which could be the source of this behavior? Again, these are TCD detectors, so could it be some other environmental factor?

Thank you.