*The system and method are given at the bottom of this post*

I am working with an Agilent 8860 operating a DB-624 UI (30m x 0.25mm x 1.4um) column with nitrogen carrier gas and split inlet (20:1). The system was shut down for approximately 1 year, and I am now working on getting it up and running. During the shutdown time, the column was left installed (ends were not sealed) with no gas flows of any kind (so water and oxygen likely entered the column). Upon start up, I cleaned the FID and conditioned the column. There was initially a lot of noise, but the baseline eventually stabilized at about 2.5-3.0 pA. Upon injecting analytes (e.g., methyl methacrylate, b.p. = 101 Celsius) dissolved in acetone at 100 ppm, I was unable to observe any signal other than that of the solvent. The signal of the solvent was varying from ~2.5 pA to 15 pA despite using the same injection and methods.

I then decided to replace the injection septum and O-ring (did not have a replacement liner, but the glass wool looked okay) and trim the first ~30cm of the column (visual inspection suggested some contamination near the column inlet). Upon reinstalling the injection assembly and column (with new ferrule), conditioning the column until a stable baseline, I am now reading consistently low acetone signals (<2.5 pA) and still not seeing any analyte (at 100 and 300 ppm).

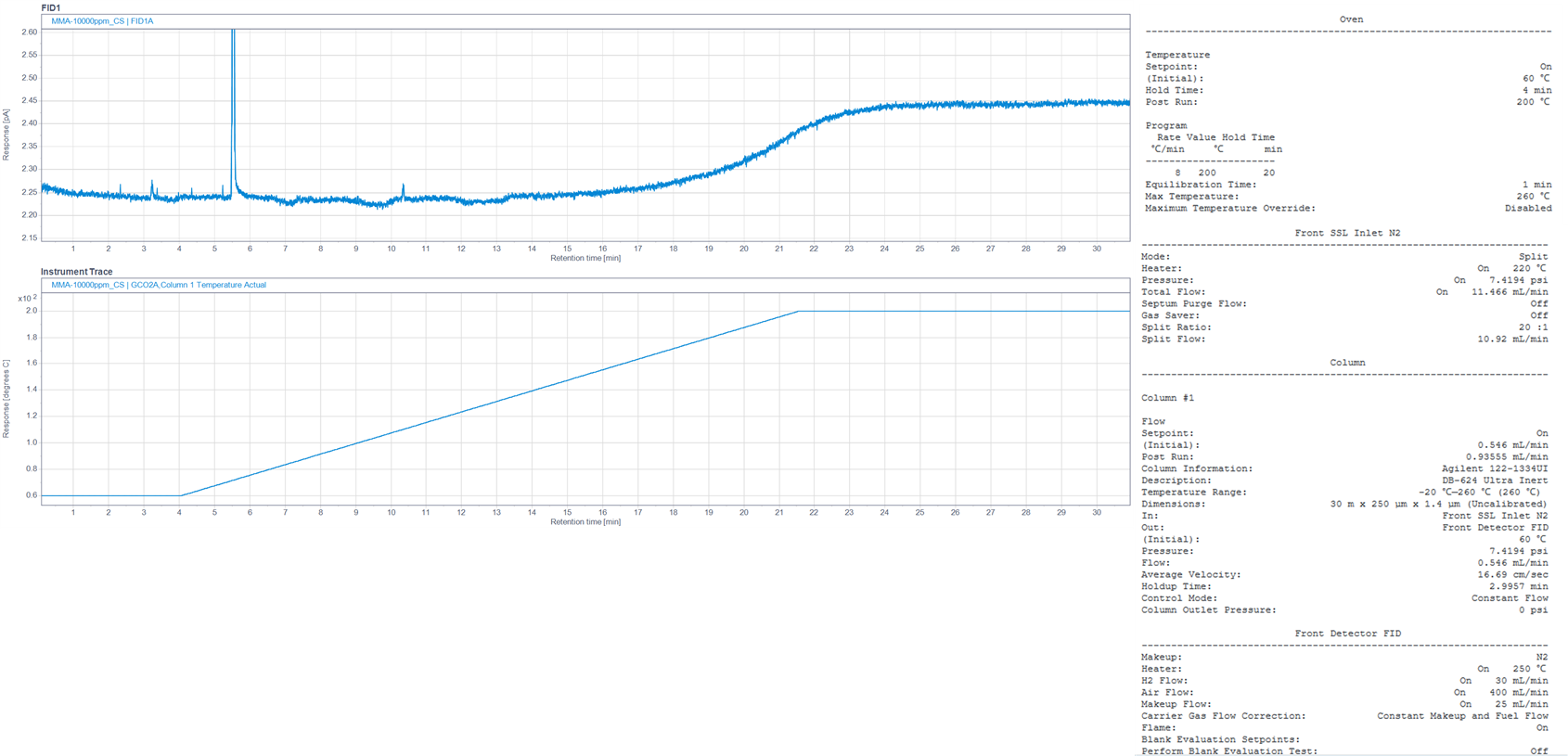

Upon looking into the last runs before the shutdown, the user was injecting analytes at 10,000 ppm. I repeated this and only saw a ~0.035 pA peak height for a 10,000ppm sample, but it was hardly discernable from the noise.

I am not sure where to go from here. I have not checked for gas leaks (no instrument for this in-house, can I use a leak-detection solution [i.e., soap water?]). We do have an extra column (HP-5), but I am trying to avoid changing the column unless absolutely necessary.

I appreciate any advice the community can offer in terms of where to go from here.

System:

- Instrument: Agilent 8860

- Injector: 76930A automatic liquid sampler

- Column: DB-624 UI (30m x 0.25mm x 1.4um)

- Carrier Gas: nitrogen

- Detector: FID

- hydrogen at 30 mL/min

- air at 400 mL/min

- nitrogen makeup at 25mL/min

- Inlet liner: Ultra inert, split, low P drop, glass wool, single taper (5190-2295 | Agilent)

Method:

- Inlet

- 1 uL injection

- 220 C

- 20:1 split ratio (split flow 10.92 mL/min)

- septum purge flow 1.63 mL/min

- Column

- 0.546 mL/min (16.69 cm/s avg linear velocity)

- Oven

- 60 C (hold 4min) - ramp at 8C/min to 200 C (hold 20min)

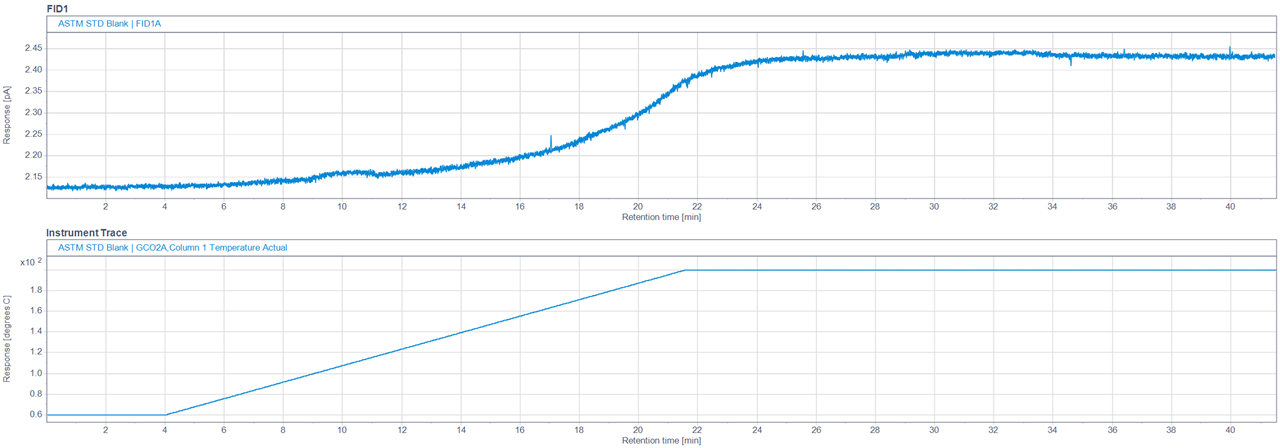

Typical baseline:

10,000ppm analyte in acetone (analyte at 10.3 minutes):