Hi All

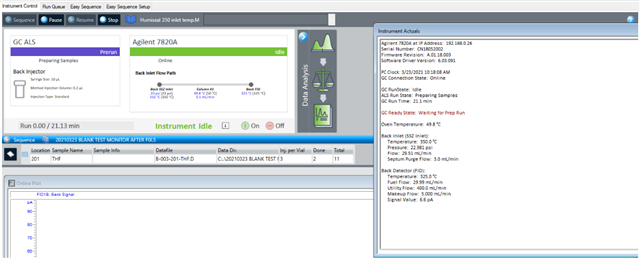

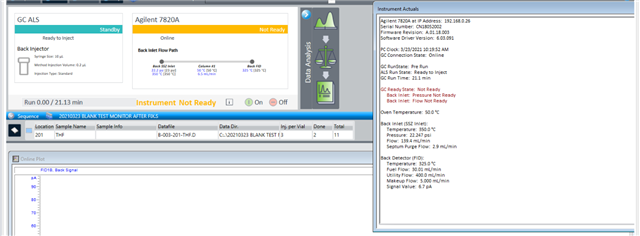

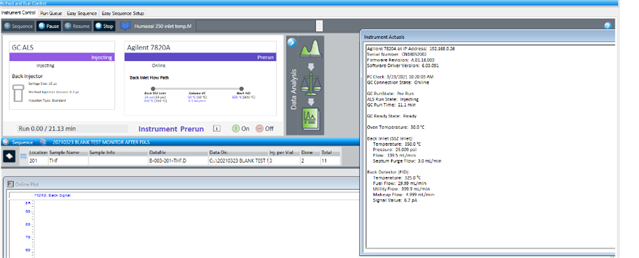

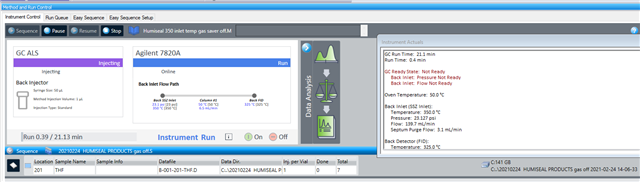

I am coming across a problem when i put a sequence of run, after the run starts when the syringe goes to wash vials it looks fine and after that sample wash looks fine, and when it comes to sample vial again to pick the sample, it stays there for long and i am getting the below message. Some times it will pick after 5 min some time it will take longer. Is there a leak

For 5 min or some times even longer it is staying there, after that it runs normal, but by displaying the same message again while it is in run.

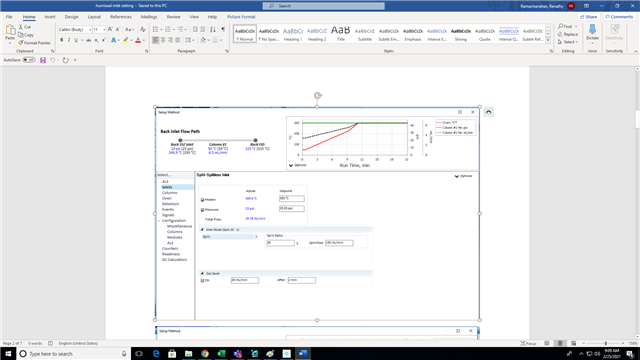

I have attached the pressure setting an it is in constant flow,

I. I tried changing the inlet, gold seal, check the coloumn end both inlet and detector end

2. The engineer changed the EPC, still i am getting this message. I tried it with gas saver mode off as well. Any sugesiton please