Hi

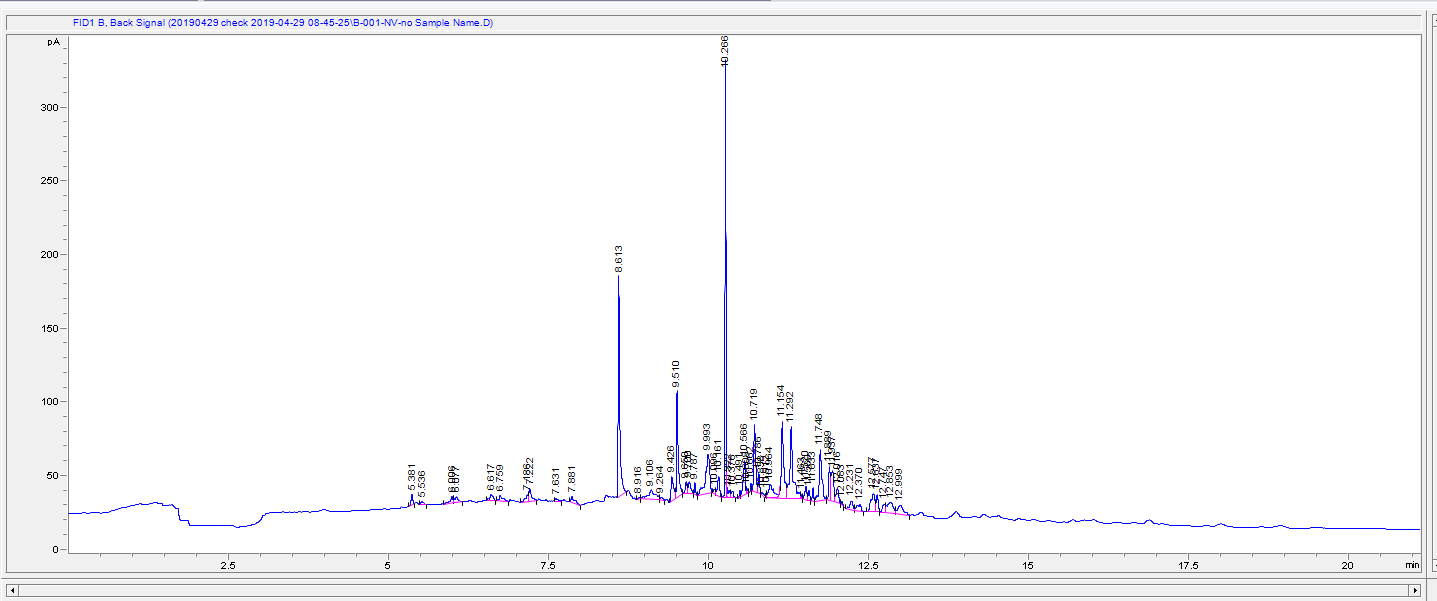

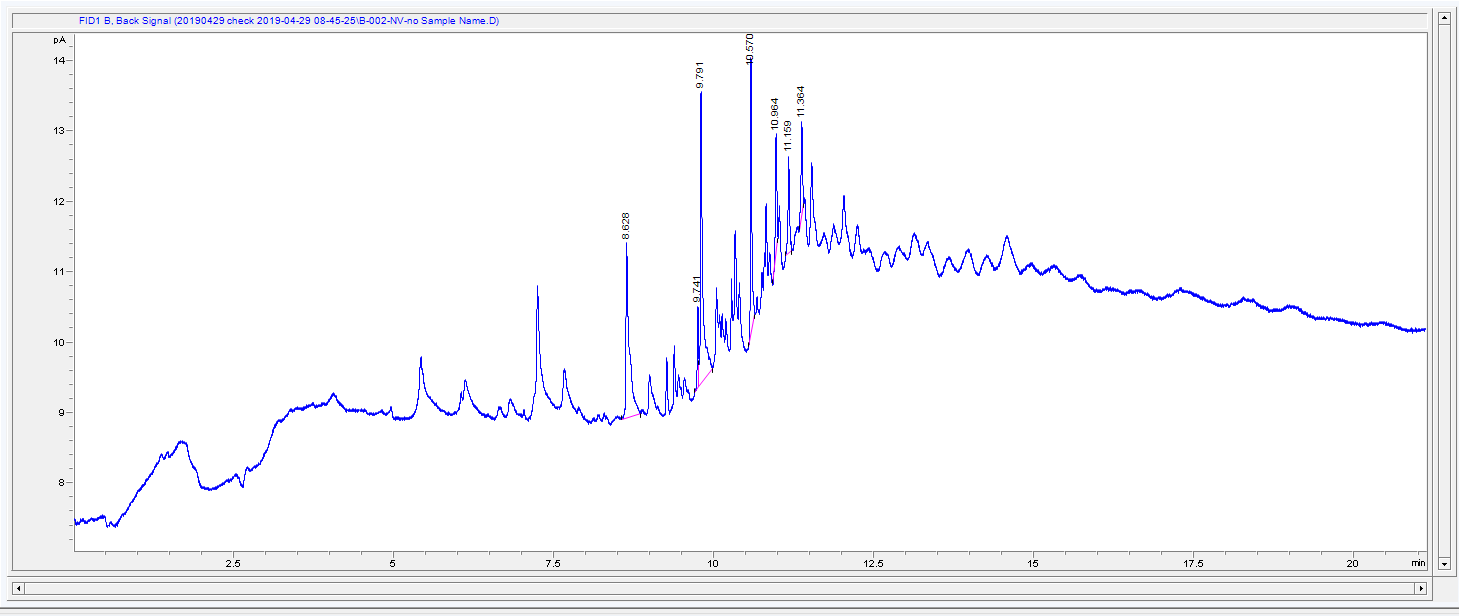

I have noticed something different this morning. I did a black run without injection( after I changed the inlet and septum) using my method(same method) continuously for three times. All the three times I am getting different chromatogram, as seen below. Can anyone help me and explain why they are different and is there anything wrong which I need to correct. I am using GC 7820 A with FID Detector.

Run 1

Run 2

Run 3

Thanks in Advance

Revathy