Hi All,

I need help to fix either baseline drifted down or change volume injection of water samples in GC/FID.

Specifically, I am setting up a new GC instrument for analysis of methanol and alcohols in water samples with the following conditions:

- Instrument: Agilent 6890 with FID detector

- Column: DB1, 60m length, 0.53mm, film 3 micron, temp limits: 60-260 oC, column flow 7ml/min

- Purge flow: 65 mL/min @ 0.01 min. Gas saver 20 ml/mi @ 2min, Mode splitless with H2 gas.

- Autosampler: Agilent 7683B

- Conditions: Initial Temp 60oC, increase 15oC/min to 120oC, then increase 25 oC/min to 220 oC.

- Detector temp: 300 oC, H2 flow 35 ml/min, Air flow 300 ml/min, make up flow 30 ml/min

- Signal: Data base 20Hz, minimum peak width 0.01 min

- Injection of 1 microL water sample using 10 microL syringe at 200 oC will create a vapor volume about 1.3 mL water vapor.

- Liner: steel line from Restek

It seems the water vapor volume is larger than the internal volume of the liner or FID detector is cooled down with a large vapor amount, chromatogram always shows a big baseline drifted down about 2 min. This well was initially covered the methanol peak. I had to optimize with temp program, column flow and purge flow.

DO YOU HAVE ANY SUGGESTION TO REMOVE THE BASELINE DRIFTED DOWN TO FORM A WELL?

Purge and column flows are two key factors to shift methanol peak off the well. However, the injections are not consistent with 30% bias with the sample spike concentration, especially with a high purge flow.

Autosampler Agilent 7683 step motor ONLY allows injecting 0.5 microL with 5 microL syringe or 1 microL with 10 microL syringe.

Then, I switched to injecting 0.5 microL water sample (vapor volume about 0.7 mL) with 5 microL syringe. The early well was still present about 2min, but the methanol was off well.

All the alcohol standard curves were perfect. The injection results were reproducible. Analysis was successful. However, the plunger of 5 microL syringe was too FLIMSY and broken all the time, especially with sticky samples. It is too costly. I had to switch back to injecting 1 microL with 10 microL syringe.

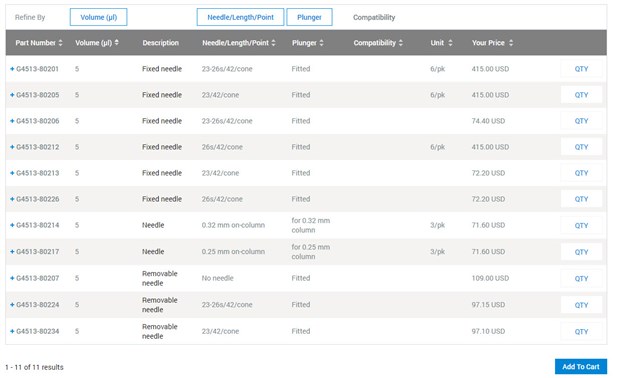

COULD YOU PLEASE SUGGEST ANY 5 microL syringe with a THICK plunger? or any autosampler or modification of autosampler can inject 0.5 microL of water samples with a 10 microL syringe?

In brief, 0.5 microL injection gave perfect results, but no practical with a large amount of samples due to broken Plunger.

1 microL injection gave inconsistent results.

Thanks a lot for any suggestion