Hi

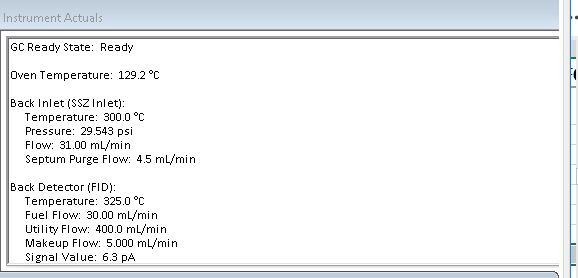

I have a very basic question, please correct me if I am wrong. I am using GC 7820 with FID detector. Flow , Pressure everything was set by another technician before I started. I know for Back Detector everything is what is set by the Technician in the method. For the Inlet, the pressure set point is 25.106 psi, split ratio 40:1. Column Flow set point 6.5mL/min with constant flow mode according to the method. But when the run is on in the Instrument actuals window shows (see below) for Back inlet, Temp which is at the set point, Pressure though the set point is 25.106 it is varying from 25 psi upto 40 psi some times I think this variation is because we have not set it as constant pressure mode. What this flow means, where it is taking the value from. There is a Total Flow section in Back inlet method, but it does'nt give any option to enter the value and I could'nt see anywhere in the method where it says this value. Today morning I noticed when the run begins the Flow started at 120 mL/min and in 2 min time it says 31 mL/min and it stays around this value till the run completes is this usaual or is there a leak anywhere.

I am using He as carrier and make up gas , Hydrogen and Air for FID. Any help would be much appreciated.

Thanks

Revathy