The Apex (Peak) vessel continues to gain momentum in the dissolution testing arena. A recently published Stimuli article from industry experts (link at bottom of article) reflects this position with supporting data from several case studies. Hear Agilent’s in-house dissolution specialist, kenboda , describe why Apex (Peak) vessels can be used as a valuable tool for troublesome products. This content was initially published on Ken’s LinkedIn page in August 2018.

Coning in dissolution can occur whenever you are working with a disintegrating dosage form, beaded formulations, powders, and some other types of dosage forms. Coning is often not a problem, and at times can be a very helpful indicator on how the dissolution is progressing (or even how well the dissolution unit is aligned). When coning is leading to artificially low dissolution, then one potential solution is the Apex (formerly known as Peak) vessel.

To begin, we should discuss coning and differentiate between good and bad cones. Coning is whenever you have a mound of material at the bottom of the dissolution vessel when performing USP Apparatus 2 (paddle) testing. The material accumulates there because this is a relatively unstirred portion of the vessel - much like the eye of a hurricane. One of the most well-known coning formulations is Prednisone.

For coning to occur, the bottom area must be a calm mixing environment. If you have a properly aligned dissolution unit, this will be the case. If your dissolution unit is off-center, vessels or shafts are not vertical, paddle height is too low, etc., you'll no longer have this same calm area in the bottom of the vessel. For this reason, the USP PVT with Prednisone is so sensitive to misaligned systems and remains a valuable tool for dissolution qualification.

The prednisone tablet is an example of what I would consider to be a good cone. By a good cone, I mean that the formation of the cone is not restricting the media from mixing with the drug product and continuing to dissolve it. Characteristics of a good cone are that it is moving, somewhat loose in appearance, and that there are particles moving outside of the cone area.

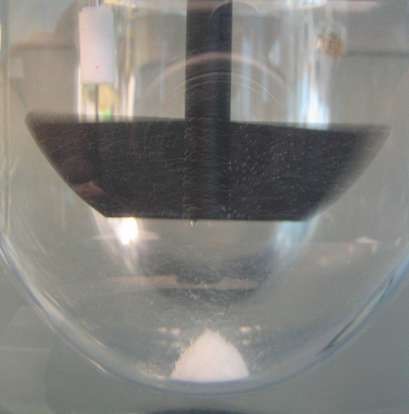

A bad cone or coning problem is when you have a cone which is restricting the dissolution process. With these cones, you will see that they are very tightly bound without particles traveling around them. They may also not have a conical shape to them such as the example below.

In these cones, typically what occurs is that you've have a layer of non-dissolving excipients form on top of the rest of the formulation. These excipients essentially will form a shield from the dissolution media, restricting access and slowing or stopping the dissolution entirely. Coning can get worse with stability samples at times. Coning most typically occurs with larger dosage forms where there is simply more mass there.

If you have problematic cones as described above, you might initially evaluate higher agitation speeds or consider testing with USP Apparatus 1 (baskets). Evaluate RPMs for paddles at 50, 75, and 100 RPM at a minimum. If you still are seeing a cone at 100 RPM for paddles, or you find that your method is not discriminatory at the higher RPMs, then the Apex (Peak) vessel might be a good fit for the product.

The Apex (Peak) vessel works by replacing the quiet zone of mixing with a peak at the bottom of the vessel. Other than the peak itself, the vessel is identical to a typical 1-Liter vessel. The paddle would be set at a height 25mm from where the bottom would be if there was no peak - there's a special height tool used to help with setting this height. With the peak in place, there is no longer a quiet zone where particles can settle, allowing you to achieve good dissolution profiles at low to moderate paddle speeds.

While Apex (Peak) vessels do not yet have prominent inclusion in dissolution chapters <711> or <1092> of the USP, they have been accepted by the FDA with products where it has been demonstrated that they have better discriminatory power. These vessels are listed as an approved part of a method for Atovaquone/Proguanil HCl in the Dissolution Method Database and have been used for other formulations as well. As with most non-compendial changes to a dissolution apparatus, you should first perform dissolution method development with the USP compendial apparatus within typical ranges and confirm there is not a good fit there.

In summary, Apex (Peak) vessels can be an excellent choice in a 2nd wave of dissolution method development where coning has been seen as a major challenge. It is a relatively inexpensive and easy modification, and one that is well understood. For more information, you can check out the following Stimuli article published in a recent issue of Dissolution Technologies:

Stimuli to the Revision Process: The Case for Apex Vessels

Or, as always, feel free to reach out to Agilent’s Dissolution Hotline at:

dissolution.hotline@agilent.com

DE60765916