Filter selection is one of the most critical and misunderstood aspects of dissolution testing. This post includes key points regarding this topic as well as important links to further information from Agilent and Cytiva filtration experts.

Why are filters important?

Filters are a critical component of the dissolution method for two main reasons. The first, and most commonly thought of, is to prevent large particles from traveling through the flow path of automated systems or analytical equipment which can cause clogging and cleaning issues.

The second job that a filter has, and the most important part of the test, is to stop the dissolution process. When an experiment is occurring, there is a mixture of solid particles traveling through the vessel. The filter must be able to screen out the undissolved drug particles as well as any excipients. The time of sample filtration defines the timepoint, not merely when the sample is removed from the dissolution vessel.

Validating Your Dissolution Filter

Dissolution filters must be properly validated for each product/method to ensure that they do not create a biased sample. Filters must be evaluated for three parameters:

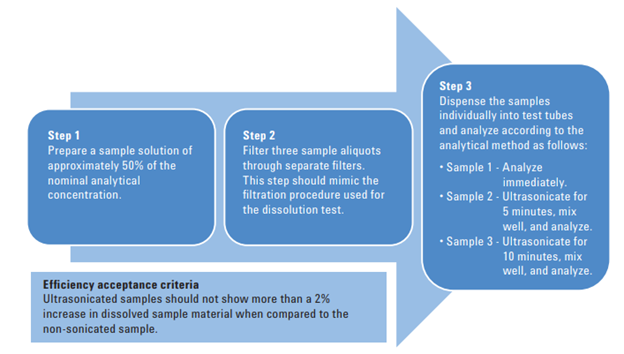

- Efficiency – the filter’s ability to remove undissolved active pharmaceutical ingredient (API) from a sample solution.

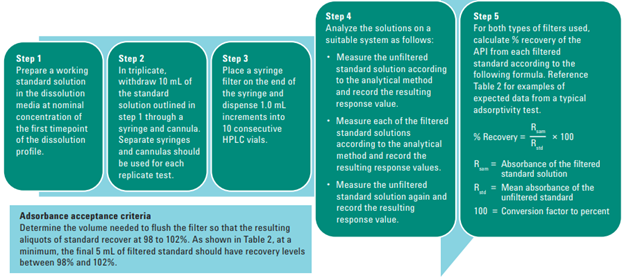

- Adsorption – filters used to clarify dissolution sample solutions should not adsorb dissolved API material onto their surfaces.

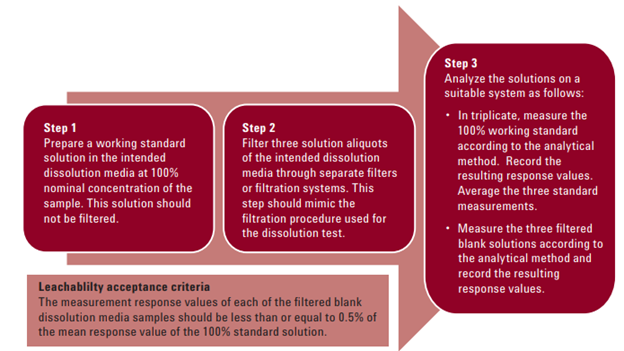

- Leachability – filters used to clarify samples must not contribute to the UV-vis spectra at the wavelength of measurement. Additionally, leachable substances must not affect the quantitative integrity of dissolved API.

Complete details and background regarding filter validation may be found at:

What Types of Filters Are Available?

Cannula filters are most commonly used for dissolution samples. These filters are typically available from 1 – 70 µm and are relatively inert, making them a suitable choice for most methods. Agilent's Full Flow filters (shown below) are an example of this type of filter.

Syringe filters can be used where filtration is required at a lower pore size than possible with a cannula filter. These filters are available in sizes from 0.2 – 1µm and can be used manually or in semi-automated or online UV-Dissolution systems, utilizing the Agilent 850-DS Sampling Station or Cary 60 UV-Vis spectrophotometer.

A third option for filtration is Hollow Fiber filters which are utilized as part of the Agilent NanoDis System. This type of filter is very useful when dealing with particles on the micro- or nanoscale where filtration is needed below 0.2 µm, or when there are challenges with capacity, blocking, or backpressure in syringe filters.

For more information about filter types, check out Agilent’s Dissolution Product Specialist kenboda recent article about this topic at:

Additional Resources

For more information, you can view a recently recorded webinar delivered by kenboda about this topic. Ken offers a step-by-step guide for how to evaluate and select the right type of filtration for even the most challenging products. This session will demonstrate the options available based on the traditional dissolution environment and how to properly validate different filter solutions with long term success and sustainability in mind.

Cytiva has also compiled a valuable knowledge center of filtration resources for dissolution – check out the following links for this information:

Lastly, and as always, feel free to post any additional queries to the Forum page of the Agilent Community or reach out directly to Agilent’s Dissolution team at dissolution.hotline@agilent.com. Thank you for reading!

DE53113395