I got your technical poster for nonylphenol ethoxylates(NPEOs) https://www.agilent.com/cs/library/posters/public/AGILENT_ASMS2018_THP174.pdf

and i also analyze to NPEO compunds from textile, dye materials with HPLCMS ULTIVO. (but not same your MRM transition. products is very different_)

but i have some issue for that.

First is getting higher column pressure.

A line is ammonium acetate buffer, B line is ACN. and column is two kinda things

Poroshell 120 EC-C18, 2.0 x 100 mm, 2.7 µm

Poroshell 120 EC-C18, 3.0 x 100 mm, 2.7 µm (the first time pressure is 200-250 bar, but after several time use the column pressure is 400-420 bar) (the pressure is first condition state and the eluent ratio is A 10%: B 90%)

is that from ammonium acetate buffer? or should I change specific column for NPEOs, OPEOs?

Second is Blank issue for NPEOs so I couldn't get low level analysis such as like you.

my lowest level is 0.1ppm that times response area is 100000. but Blank (just Methanol, the all of sample dilute methanol) is 50000. (almost half area. most detected products ion is 271,315,485,529,573)

because of the problems, calibration response can not make a ratio with standard concentration level. (if you get 0.1 ppm 10 response area, response of 0.5ppm have to 50 but ours 30 response area.)

so I couldn't get right quantitative result.

and how can make calibration curve (figure 6)? just only one compounds? or all of NPEOs get together? such as a sum of all response area?

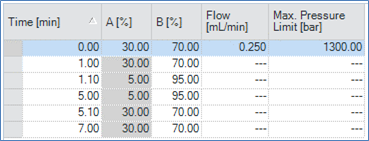

can i get that poster detail information? such as column, gradient time table(plz table, i couldn't understand well just explain thingies), recipe for buffer solution with all materials CAS NO. and source information.

several times i asked person in charge of your Korea branch. but couldn't get any answer. so plz help me.

AND YOU CAN CONTACT MY E-MAIL