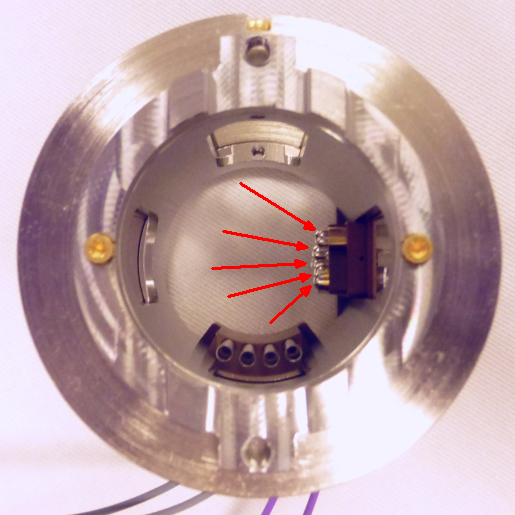

Hi, I cleaned the ion source of G7012B a month ago. I cleaned the ion source and replaced the filament. Ever since I installed it back, there has been this 1.5 entrance lens voltage error message showing up at random times. It pops up during the pre-run stage and abandons the run and the rest of the sequence. The frequency was like once every 3-40 runs (sometimes very frequent and sometimes not so much).

Earlier this week, I took the ion source out and checked the lens and connections. They all seem ok to me. I was able to conduct an autotune the next day. But the issue remains as the same msg pop up after about 25 runs last night. I would like to know what is probably wrong and what I can do next.

The signals are all good. I don't see other issues with the MS data.

Thank you!