HI All,

I did a test as specified below to check if there is any issue with the Split Vent. There is a pressure build up when I closed the hole with my finger. Does that indicates the valve is broken and I need to call the Agilent to fix it?

Would this affect the RSD(%) of injections? I am having an issue with my injection repeatability.

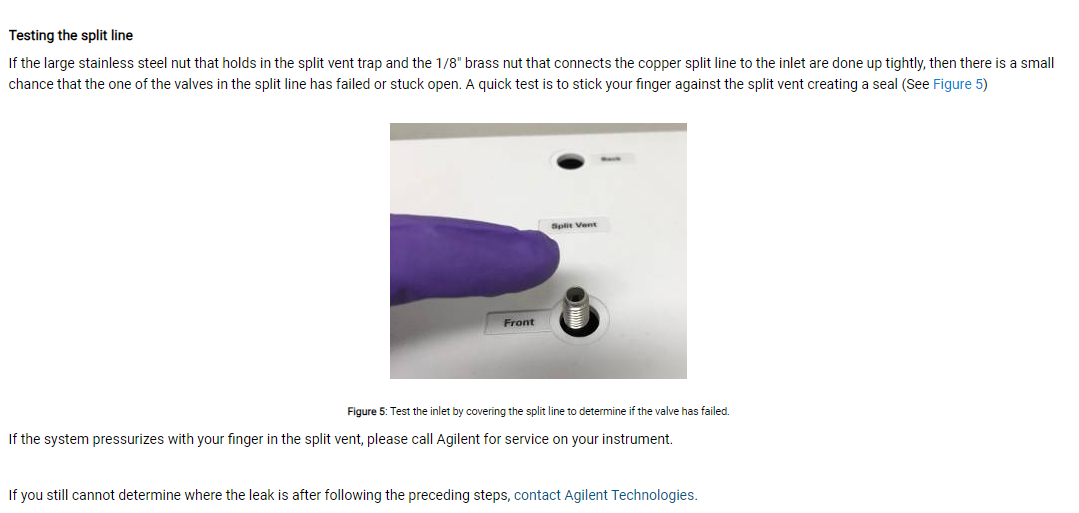

Troubleshooting a Leak in a Split/Splitless Inlet - Articles - GC Portal - Agilent Community

Thank you

Regards

Kris