I’m the first GCMS blogger for the Agilent Customer Community and this is article number 1. We’ll navigate through the GCMS talking about how it works and what needs to be done to keep one running smoothly. That is going to take a while, I think!

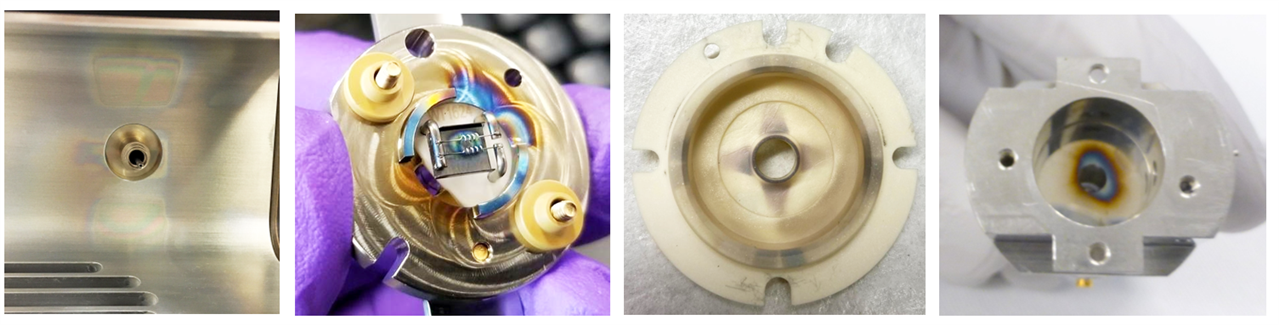

The primary normal user maintenance for a GCMS is Ion Source Cleaning. Let’s demystify the relatively straightforward procedure and dispel some myths.

Everything that comes out of your column goes into the mass spectrometer.

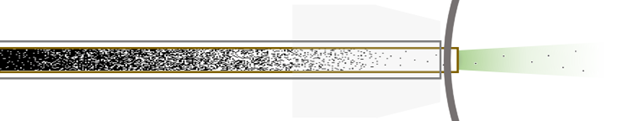

We speak of the speed of column flow as average linear velocity. Average. Like “44.7 cm/sec”, which happens to be one mile per hour. That velocity is not constant, though. At the inlet, there are innumerable molecules jammed together under pressure - nanometers apart - and at the end of the column in the MS there is enough space between molecules for them to be able to fly a few meters without hitting another one. The flow in the column goes faster and faster as there is less and less restriction heading into the MS.

At the end of the column into the MS, everything comes out in molecular flow, which is not flow at all, but molecules in vacuum moving in a straight line. This happens when the empty space between molecules is longer than the column inside diameter, somewhere near the end of the transferline. Now the innumerable molecules are going in the thousands of miles per hour into the ion source!

There is no flow in a vacuum, only molecules bouncing with empty space in between, that mean free path thing. Everything that comes out of your column goes into the MS, molecules bouncing all over, or sticking and then releasing to bounce and stick again, until they either stay attached or continue to bounce their way around and into the opening of the high vacuum pump. For an electron ionization source, it is frequently stated that only about 0.1% of the molecules are ionized and not all of those ions make it down the quadrupole to the detector. 99.9% of the molecules aren't ionized and they are bouncing around touching everything.

At GCMS vacuum levels, molecules that come out of the column contact every square millimeter of every surface inside the chamber in less than three seconds. It is not an even distribution for all molecules, though. Some have bounced, stuck, and taken up residence, depending on their boiling point in a vacuum among other variables. The ones that are stuck already may grab onto other molecules, too. This adhered layer continuously redistributes.

When molecules stick on the active electrostatic components of the source they interfere with the electrostatic fields. Part of tuning is changing the fields to accommodate this. As the adhered layer on the active components grows, the source efficiency degrades and the tuning changes.

Everything that comes out of your column goes into the MS.

- All of the sample that made it into the column - solvent, matrix, peaks of interest, contaminants

- Column bleed if you are running with an air leak and the oxygen is damaging the column phase

- Gas contaminants if your traps are full or the gas had problems from the supplier

You can reduce the amount that goes into the mass spec by injecting the smallest volume, running the highest split ratio with the lowest concentration with the cleanest samples you can. The source stays really clean if you don’t run anything. The better you do those steps the cleaner the system stays and the less maintenance that needs to be performed along with the least number of consumables used. If you don’t, or can’t because of your samples, then you need to accept that there will be increased maintenance, consumables, and the associated costs.

The adhered layer must be removed to maintain proper function of the mass spectrometer. Removing the residue is normal user maintenance – cleaning the source. Molecules also stick on the inactive electrostatic components, like the inside of the ionization chamber, the insulators, and the source body. These redistribute in the heated vacuum environment and some will go right onto any freshly cleaned parts. Clean all parts of the entire assembly and clean or replace the insulators often.

The frequency of cleaning depends on the sample, the number of samples, and the way the instrument is run – how much is injected, inlet mode, temperatures, etc. Routine maintenance is not included in the hardware repair contract. It is paid for once during the preventive maintenance but most systems need more, much more. Don’t wait! Cleaning early and often means that you don’t need to work as hard. While it is apart, clean it thoroughly, every surface, face, nook, cranny, edge, window, and hole, inside and outside, every place that is possible.

In summary:

- Everything that comes out of your column goes into the MS.

- Cleaning the residue out of the MS is normal user maintenance.

- Clean it often. Don’t let it accumulate.

- Be thorough. While it is apart, clean everything you can.

There are videos available that cover in detail all the necessary steps to clean the ion source.

1:09:06 (3) GCMS Ion Source Cleaning - Videos - GC/MS Portal - Agilent Community

26:29 (3) How to Clean Your High Efficiency Ion Source - Videos - GC/MS Portal - Agilent Community

23:25 (3) How to Clean Your Chemical Ionization Ion Source - Videos - GC/MS Portal - Agilent Community

15:44 (3) GCMS Rough Pump Options and Changing Rough Pump Oil - Videos - GC/MS Portal - Agilent Community

DE08546168

.

.

.

.

.

.