Hi everyone,

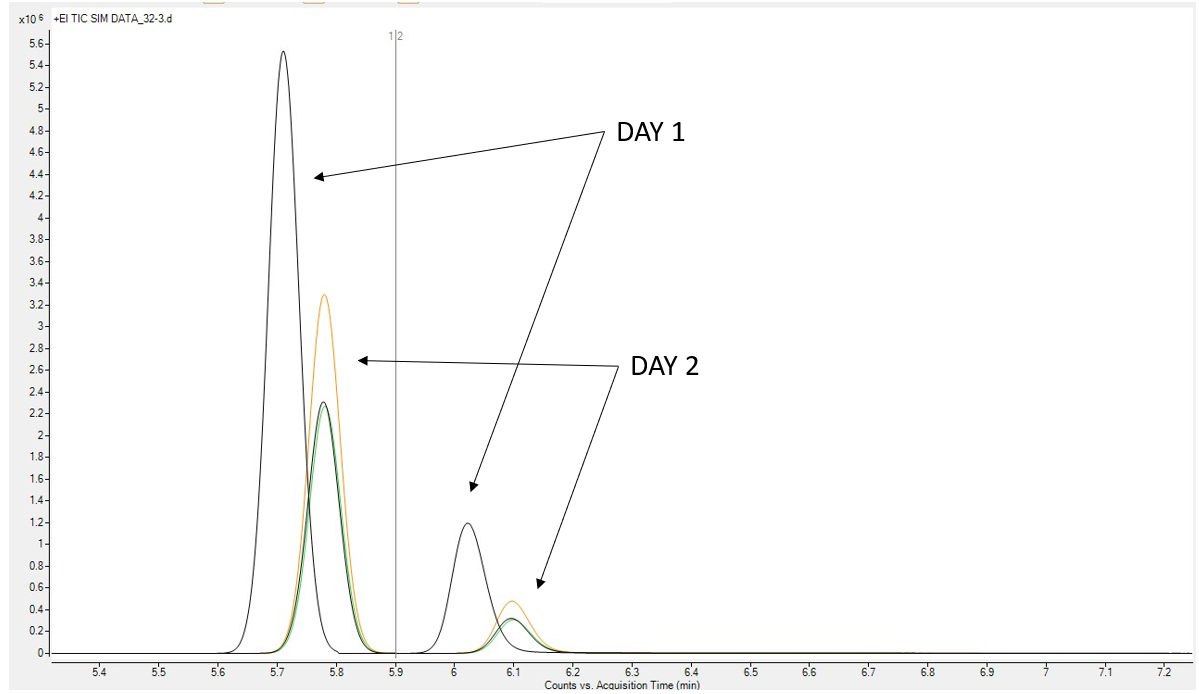

Can somebody advice me on what could be possible cause of retention time shift and unstable areas (meaning poor repeatability) in GCMS? I have included picture below where day1 and day2 means that standards were run in different days. Is that a normal behaviour? Our system is INTUVO GCMS thus we are not cutting our columns or anything like that because we are using guard chips instead.

The GC method is attached as text file

INSTRUMENT CONTROL PARAMETERS: GCMS

--------------------------------------

Fri May 27 14:00:29 2022

Control Information

------- -----------

Sample Inlet : GC

Injection Source : GC ALS

Injection Location: Front

Mass Spectrometer : Enabled

No Sample Prep method has been assigned to this method.

GC

GC Summary

Run Time 16 min

Post Run Time 0 min

Cycle Time Optimization Fast Cool (default)

Oven

Temperature

Setpoint On

(Initial) 70 °C

Hold Time 7 min

Post Run 70 °C

Program

#1 Rate 20 °C/min

#1 Value 150 °C

#1 Hold Time 5 min

Equilibration Time 0.25 min

Max Temperature 240 °C

Maximum Temperature Override Disabled

Slow Fan Disabled

ALS

Injector

Syringe Size 10 μL

Injection Volume 0.2 μL

Solvent A Washes (PreInj) 3

Solvent A Washes (PostInj) 3

Solvent A Volume 4 μL

Solvent B Washes (PreInj) 3

Solvent B Washes (PostInj) 3

Solvent B Volume 4 μL

Sample Washes 3

Sample Wash Volume 4 μL

Sample Pumps 6

Dwell Time (PreInj) 0 min

Dwell Time (PostInj) 0 min

Solvent Wash Draw Speed 300 μL/min

Solvent Wash Dispense Speed 6000 μL/min

Sample Wash Draw Speed 300 μL/min

Sample Wash Dispense Speed 6000 μL/min

Injection Dispense Speed 6000 μL/min

Viscosity Delay 0 sec

Sample Depth Disabled

Injection Type Standard

L1 Airgap 0.2 μL

Solvent Wash Mode A, B

Sample Overlap

Mode Sample overlap is not enabled

ALS Errors Pause for user interaction

SS Inlet He

Mode Split

Heater On 250 °C

Pressure On 2.0699 psi

Total Flow On 57 mL/min

Septum Purge Flow On 6 mL/min

Pre-Run Flow Test On

Pre-Run Flow Test Action on Failure Abort

Gas Saver Off

Split Ratio 50 :1

Split Flow 50 mL/min

Liner A Liner has not been selected.

Column

Column #1

Flow

Setpoint On

(Initial) 1 mL/min

Post Run 0.57353 mL/min

Column Information Agilent 123-9334UI-INT: US20400239

DB-BAC1 UI

Temperature Range 20 °C—270 °C (270 °C)

Dimensions 30 m x 320 μm x 1.8 μm

Column lock Locked

In SS Inlet He

Out MSD

(Initial) 70 °C

Pressure 2.0699 psi

Flow 1 mL/min

Average Velocity 30.691 cm/sec

Holdup Time 1.6291 min

Control Mode Constant Flow

Column Outlet Pressure 0 psi

Agilent Intuvo 9000 GC Components

Guard Chip

Temperature

Setpoint On

(Initial) 210 °C

Post Run 100 °C

Model Number G4587-60565: Intuvo SSI Guard Chip

Track Oven Off

Max Temperature 450 °C

Isothermal Setpoints

Bus Temperature On 200 °C

Use Default Bus Temperature On

Valve 1

Type Gas Sampling Valve

GSV Loop Volume 1 mL

Load Time 0.5 min

Inject Time 0.5 min

Signals

Signal #1: Test Plot

Description Test Plot

Save Off

Data Rate 50 Hz

Signal #2:

Description None

Signal #3:

Description None

Signal #4:

Description None

MS Information

-- -----------

General Information

------- -----------

Acquisition Mode : SIM

Solvent Delay (minutes) : 4.5

Tune file : D:\MassHunter\GCMS\1\5977\ATUNE.U

EM Setting mode Gain : 5.000000

Number of SIM Groups : 2

Run Time (if MS only) : 650 minutes

[SIM Parameters]

Group 1 Group ID : toluen

Resolution : 0

Group Start Time : 4.5

Number of Ions : 2

Ions

Dwell In Group :( Mass, Dwell) ( Mass, Dwell) ( Mass, Dwell)

( 91.00,50 ) ( 92.00,50 )

Group 2 Group ID : amyl alcohol

Resolution : 0

Group Start Time : 5.8

Number of Ions : 2

Ions

Dwell In Group :( Mass, Dwell) ( Mass, Dwell) ( Mass, Dwell)

( 55.00,50 ) ( 70.00,50 )

[MSZones]

MS Source : 230 C maximum 250 C

MS Quad : 150 C maximum 200 C

Timed Events

----- ------

Number Events= 0

END OF MS ACQUISITION PARAMETERS

TUNE PARAMETERS for SN: US1422L218

---------------------------------

Trace Ion Detection is OFF.

34.593 : EMISSION

70.007 : ENERGY

31.712 : REPELLER

90.331 : IONFOCUS

17.627 : ENTRANCE_LENS

1121.040 : EMVOLTS

1388 : Actual EMV

5.00 : GAIN FACTOR

358.000 : AMUGAIN

123.938 : AMUOFFSET

1.000 : FILAMENT

0.000 : DCPOLARITY

15.482 : ENTLENSOFFSET

0.000 : Ion_Body

0.000 : EXTLENS

-1040.000 : MASSGAIN

-35.000 : MASSOFFSET

END OF TUNE PARAMETERS

----------------------

END OF INSTRUMENT CONTROL PARAMETERS

------------------------------------

Best Regards,

Standwi